"HEATING", Soldering News: The Truth About Soldering[Youtube Tech Article]

YOUTUBE Tech Article!

The Truth About Soldering – Soldering News: The Heating Edition

Table of Contents

- Theme

- Overheating

- Improving Heating Efficiency

- Summary

- Related Products & Services

- Video of This Article

Video for This Article

Theme

Y Hello everyone. It’s time for Soldering News, where we tell the truth about soldering. I’m Yanaka, and I’ll be your host.

You might know that there are several important elements in soldering, but today we’re going to talk about heating.

Overheating

Y Heating is the most crucial element in soldering. Insufficient heat results in solder not sticking or not flowing properly, leading to defects.

But what happens when you overheat? We have footage to show you. Please watch.

In this video, we continue heating at a high temperature setting of 450°C. The excessive heat caused the pad to peel off. As demonstrated, compared to normal soldering, overheating can lead to damage to the PCB or components.

Hopefully, you understand why overheating is not advisable.

Improving Heating Efficiency

Y Next, let’s focus on how to efficiently transfer heat.

Indeed, increasing the set temperature can enhance heating power and make heat transfer easier, but as seen in the previous footage, it can also damage components and shorten the lifespan of the soldering tip. So, from here, we will discuss how to improve heating efficiency without raising the soldering tip’s set temperature. Please watch this video.

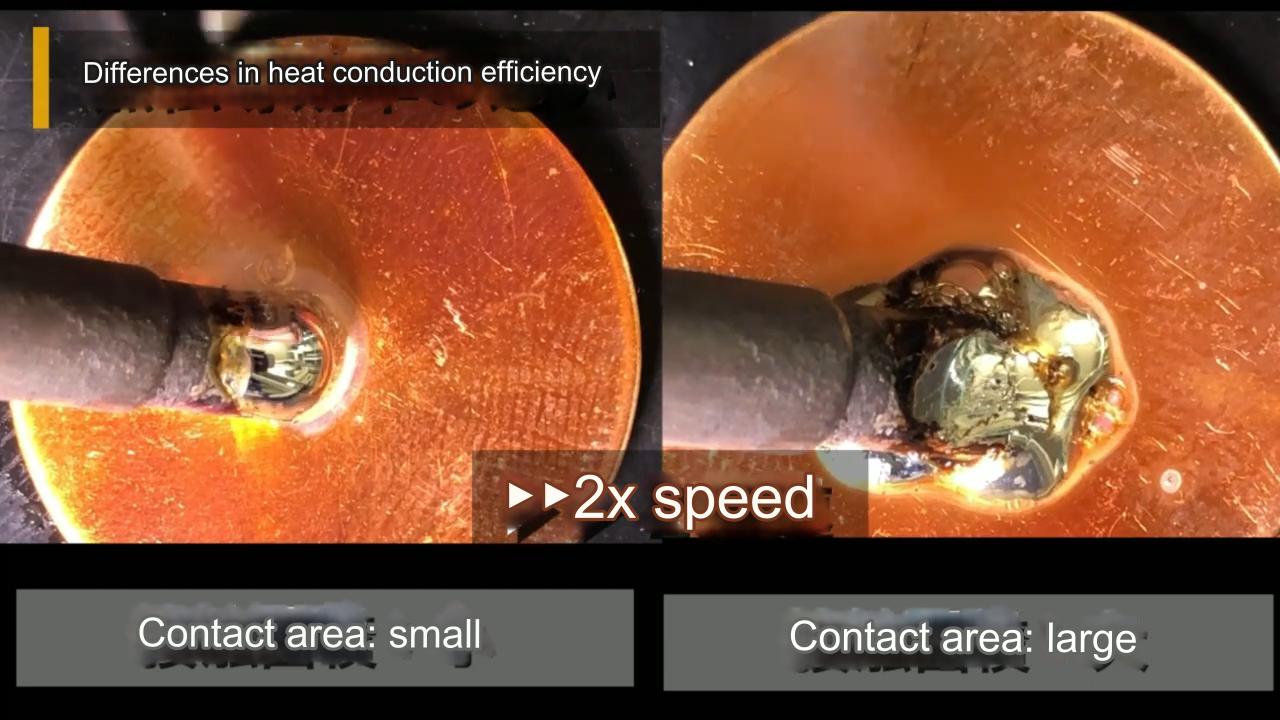

This video compares the heating conductivity efficiency. On the left, the soldering tip has less pre-solder, while on the right, there is more pre-solder during heating. The side with more is already adapting. The left side is finally catching up.

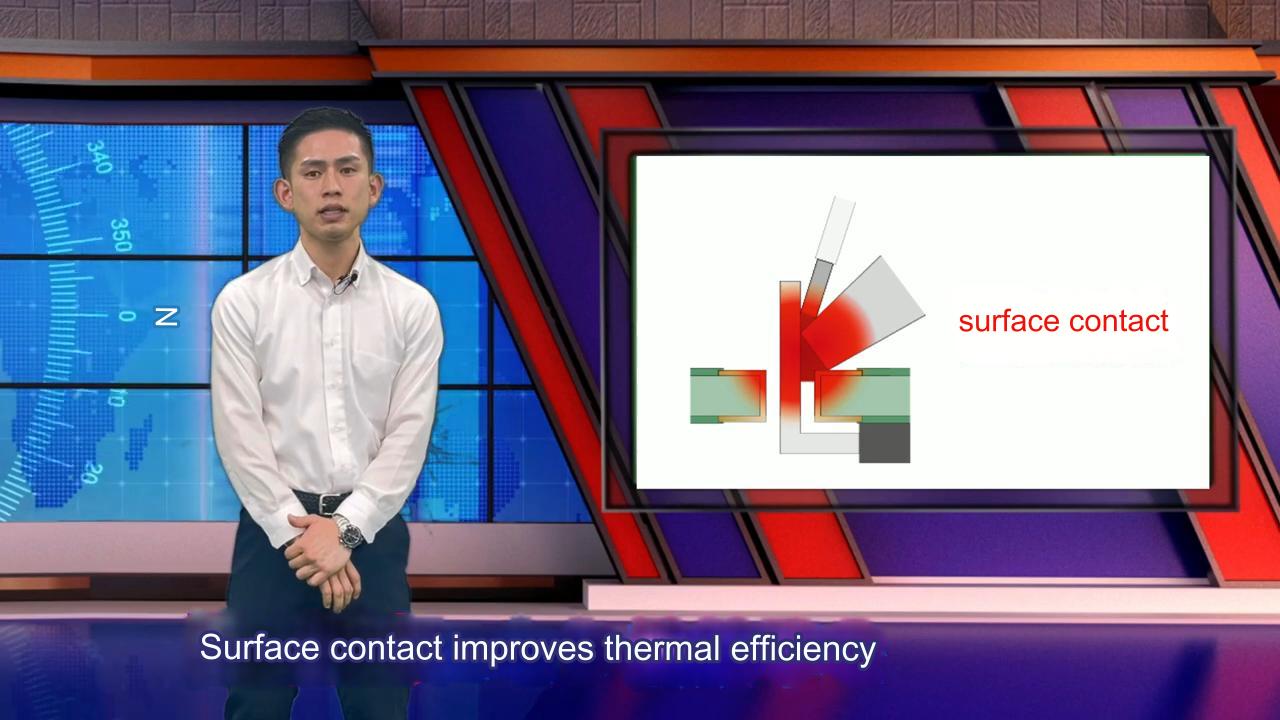

As you can see, the amount of solder supplied significantly affects heating efficiency. The difference in heating efficiency comes down to point contact versus surface contact. With less solder, the contact area with the component is small, resulting in point contact.

Conversely, with sufficient solder, the contact area is larger, resulting in surface contact, which can increase heating efficiency.

Summary

Y From these two videos, you should understand how crucial it is to manage the heating time and the amount of solder supplied in soldering.

Our channel will continue to deliver the truth about soldering. See you in the next video. Goodbye.

Related Products & Services

Video for This Article

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español