Soldering Robot

Automated Soldering Solutions

Top in Variety of Automated Soldering Products

Japan Unix offers a unique lineup of automated soldering robots and systems, built on our own soldering theory and automation experience. We provide flexible models and setups to fit each customer’s needs.

Product Lineup

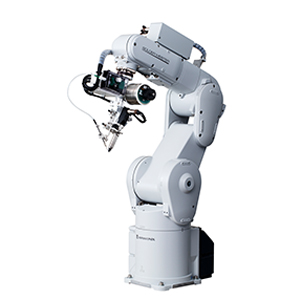

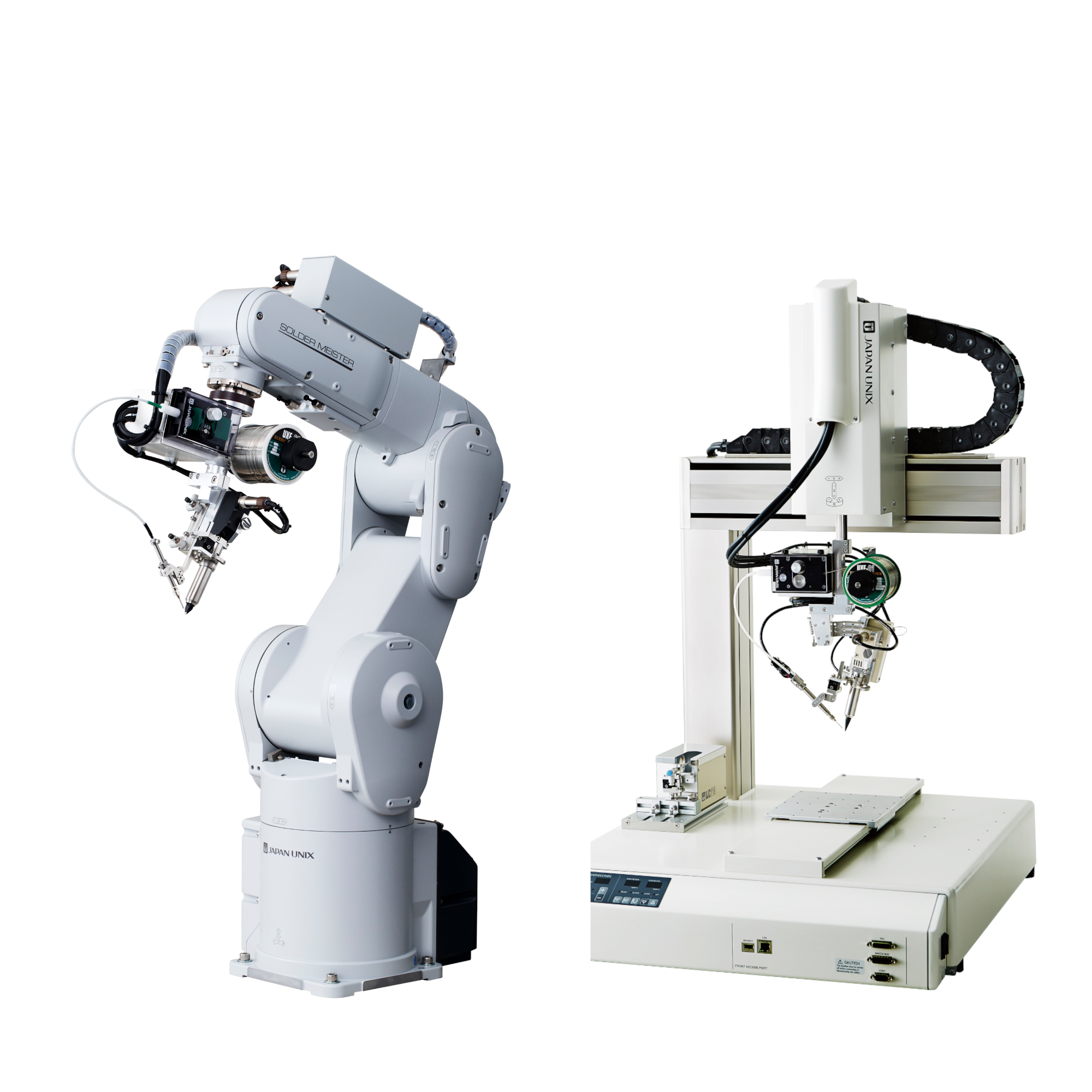

Multiple-joint Soldering Robot

The highest-end model for full automated soldering line. It can provide high-quality work on the most difficult workpieces.

Desktop Soldering Robot

Versatile desktop type. Once programmed, it can consistently perform with the same quality as a skilled operator by simply pressing the start button.

Gantry Type Soldering Robot

Gantry type robot has optimized for in-line automation that is as easy to use as a desktop type.

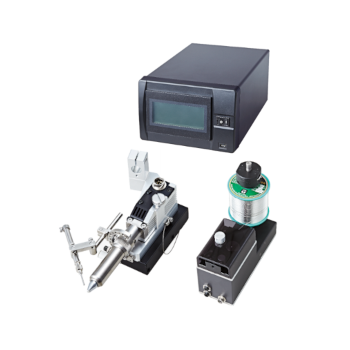

Optional Equipments

The challenges of the soldering process are varied. We offer a rich set of expandable options based on customer feedback.

Automation Unit

By using units equipped with soldering know-how accumulated by Japan Unix, you can automate the process with your own equipment.

System Integration

We customize the equipment to meet the customer’s needs. We will propose the most suitable soldering equipment.

Consumables

We offer a wide variety of high-quality consumables such as tips and laser parts.

Choice of Automated Soldering Installations

Soldering Automation

Japan Unix provides automated soldering solutions based on original theory and experience. Our robots and systems solve challenges like lead-free soldering, heat dissipation, and high-density PCBs.

Integration

Want to integrate and fully automate, including conveyer system.

Soldering Robot

Want to use a soldering robot with a proven performance.

Soldering Unit

Want to automate soldering process utilizing the existing equipment.

Additional Options for Soldering Automation

By combining a wealth of additional functions, higher quality, more accurate soldering and shorter cycle time can be achieved.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español