R&D Center

Over 1,000 verification experiments from all over the world every year

The world’s only soldering research institutes (soldering labs) gather together the latest soldering machineries and a variety of soldering equipments. The lab develops the foundation and new methods of soldering technology with utilizing advanced analytical tools.

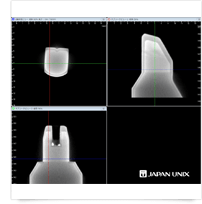

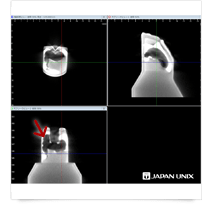

Micro X-ray CT

e.g. internal tip erosion and non-destructive inspection

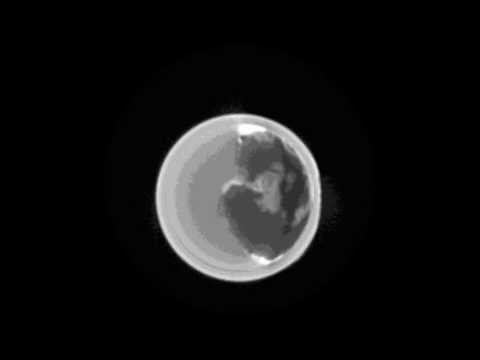

Nano-focus X-ray CT

e.g. Non-destructive inspection of micro-voids in the soldering point

Tensile Strength Testing Machine

Bonding strength analysis

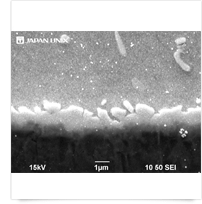

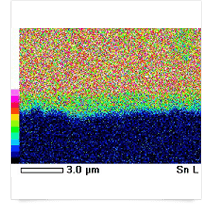

Analyzing soldering condition (SEM)

Observing PCBs and soldering tip(CT scan)

Experiments of robotic soldering

The number of soldering tests brought to us every day that we implement and verify totals over 1,000 per year. It includes unprecedented and exceedingly difficult orders that clients have been unable to find solution. Here are some analytical examples that soldering labs clarify and define the quality in soldering

Strength analysis of solder joints

Connectivity of substrate and soldered points

Analysis of intermetallic compounds

Observation of diffusion layer

Non-destructive analysis of tips wettability

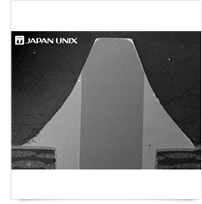

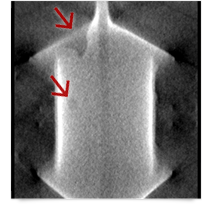

Inside of the new tip

Erosion was found inside of the soldering tip (like cavity)

Abnormality unseen to the eye (analyzed tip)

Soldering condition of a sealed product

Checking for solderability in through holes

Through hole X-ray analysis

Found blow holes and voids that can not been seen from the outside

Our soldering lab employs specialized, experienced engineers with the latest tools and established soldering theories in order to meet the needs and challenges of a wide variety of customers.

Please contact us if you could consider our experience and skills in solving your problems.

Other Analysis Examples

Aluminum plate soldering SEM analysis (x 1,000)

X-ray tracing image of soldering tips

Checking for inside erosions of soldering tips (like cavity)

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español