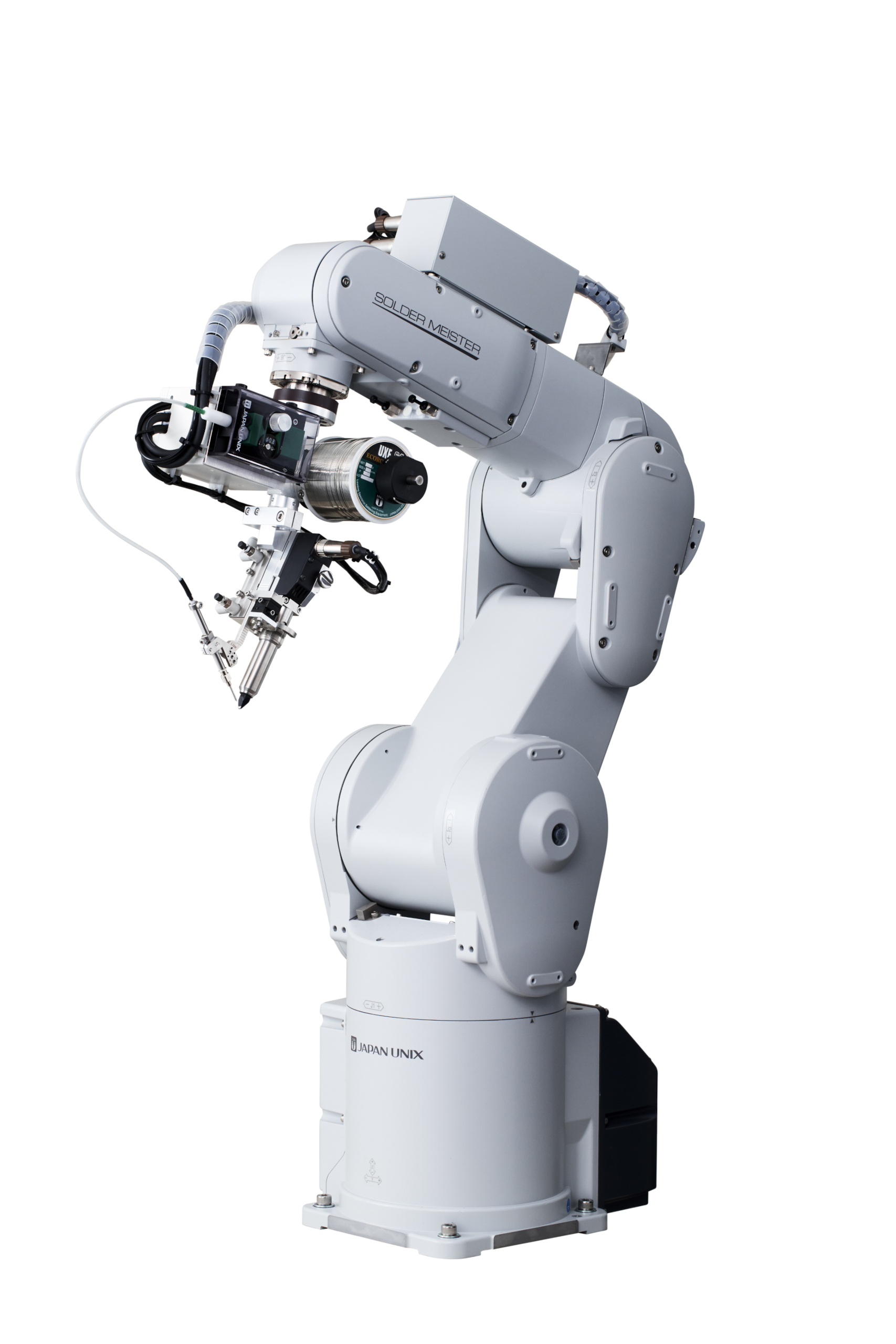

Soldering Management Software

Soldering IoT Starting in the Production Line

Soldering Manager

Real-time display and visualization of soldering robot operation status. Recording video and data during soldering enables

higher process control at the production site.

The system also supports serial management by reading 2D codes, which,

together with the recording function, provides enhanced traceability.

Software is available for laser soldering

as well as soldering with a soldering iron.

Feature

What is the “Soldering Manager” ?

CONNECT

Connect PC, camera, and thermometer to robot

DIGITIZE

Enables automatic storage of data during operation

VISUALIZE

Visualization of temperature and other data during soldering

CAPTURE

Save numerical data and video (CSV format, MPEG-4 format)

ARCHIVE

Stored data can be utilized, and serials can be managed by

reading 2D codes.

CONNECTIVITY

Conforms to IPC CFX,

SEMI, Hermes, and other standards and connects soldering data to other equipment

For More Connected Facilities

Temperature and other measured values from optional equipments are also recorded and stored in the Soldering Manager for more integrated process control.

<Iron Tip> Connecting to the UNI-TESTER soldering iron tester enables recording of measured values for soldering iron tip temperature, leakage voltage, and resistance to ground, as well as automatic offset of soldering iron tip temperature.

<Laser> Displays and records soldering temperatures measured by the Thermo Pro™ temperature control function .

Interface

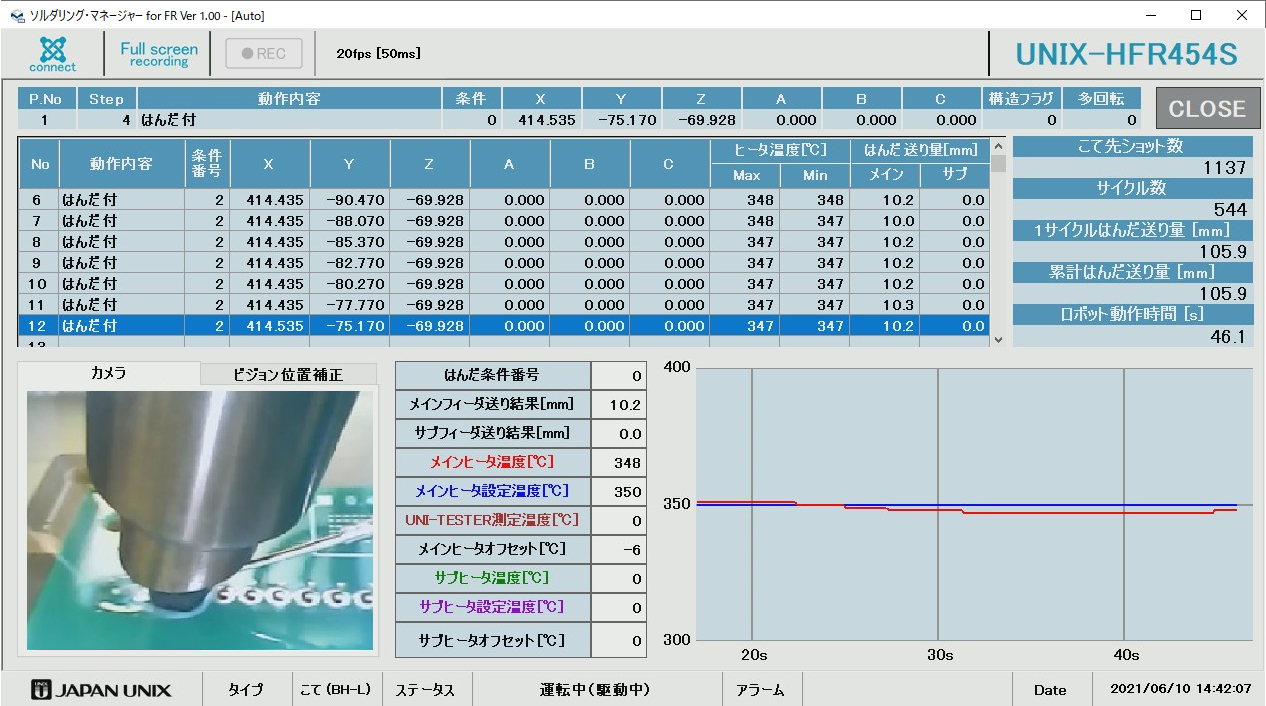

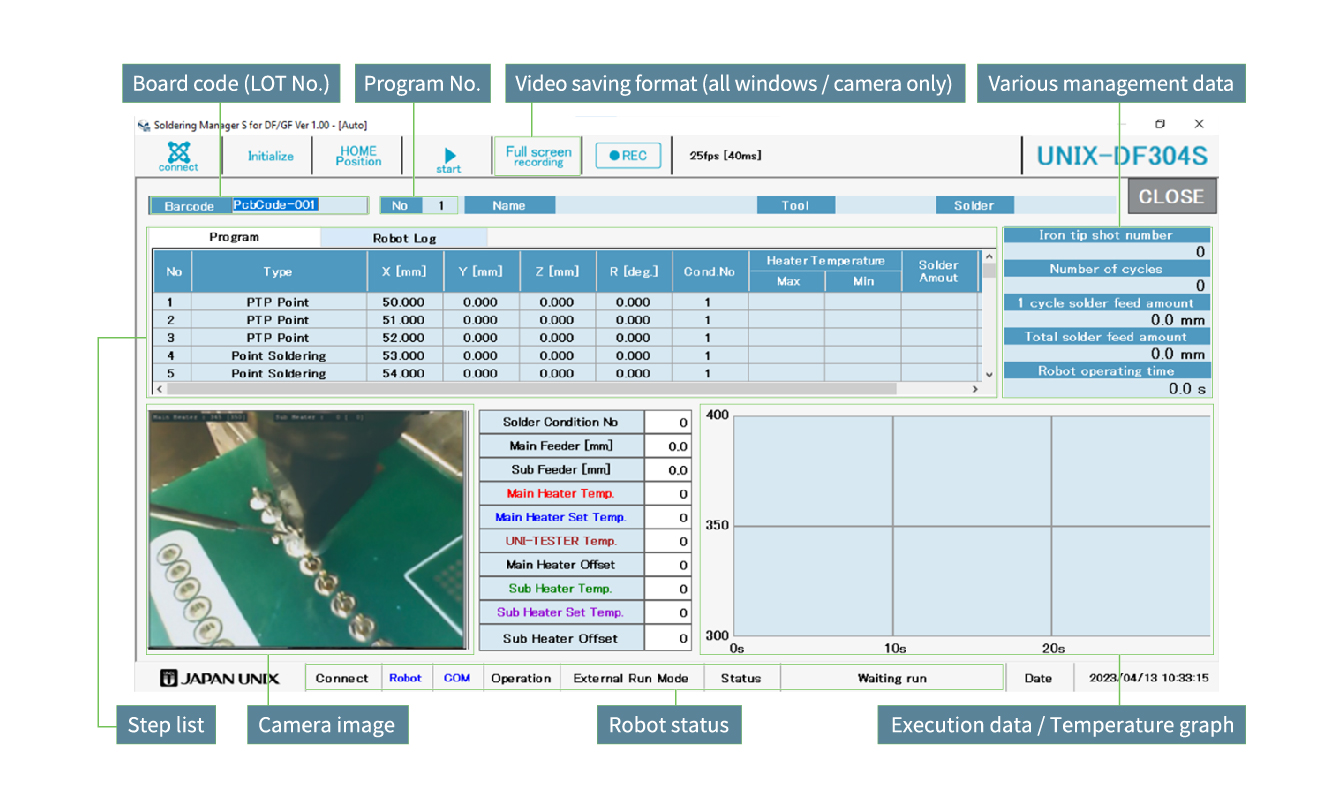

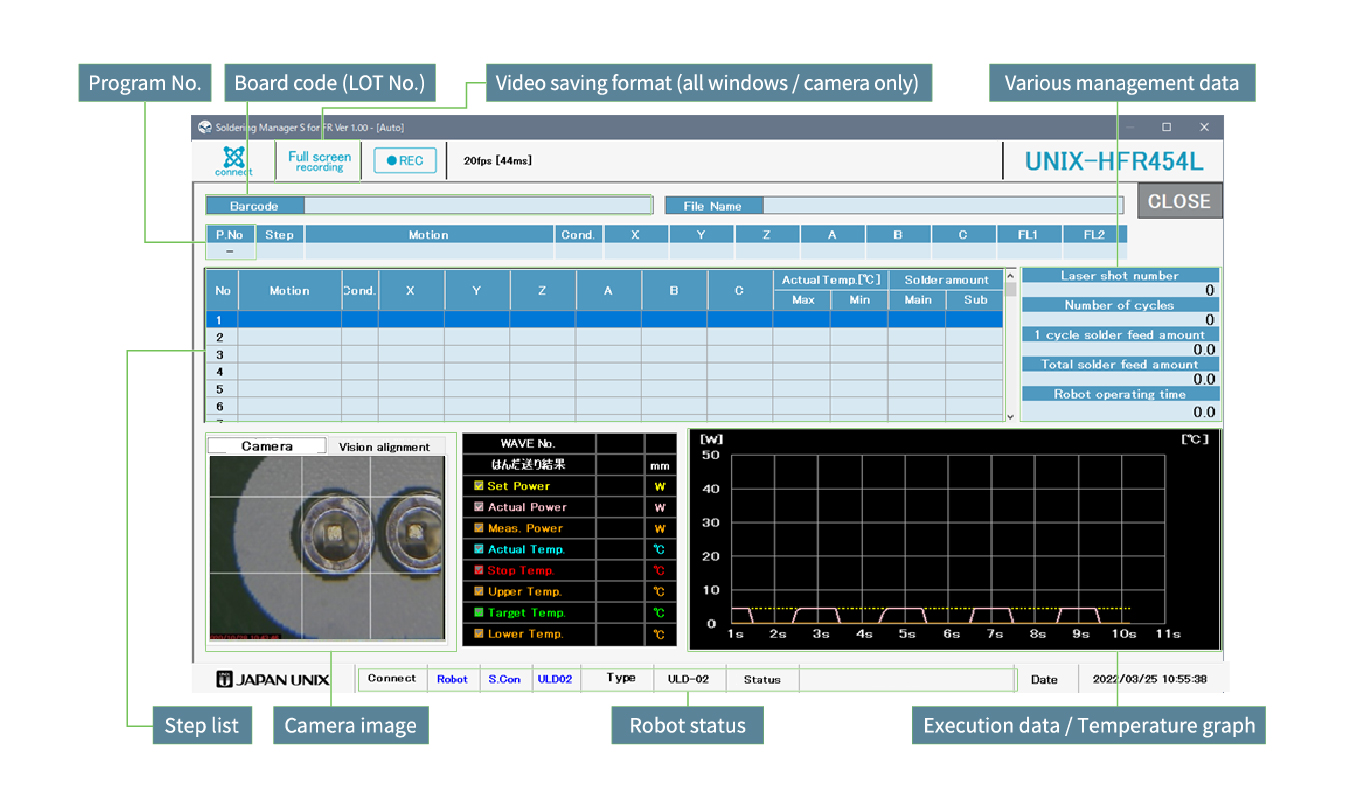

Soldering Manager (for iron tip)

- Visualization of the robot’s operational status, including coordinates for each point, various counters, tip temperature, etc.

- All correction values by the 3-axis tip position correction mechanism, temperature measurement values by UNI-TESTER, automatic offset values, tip grounding resistance, and leakage voltage are recorded.

- Video and data recording during soldering enhances traceability

- Serial management by reading 2D codes

- Global process control is possible by sharing acquired data

UNIX-DF series (iron tips), UNIX-GF series (iron tips)

UNIX-FR series (iron tips)

*Cannot be used with AD heaters.

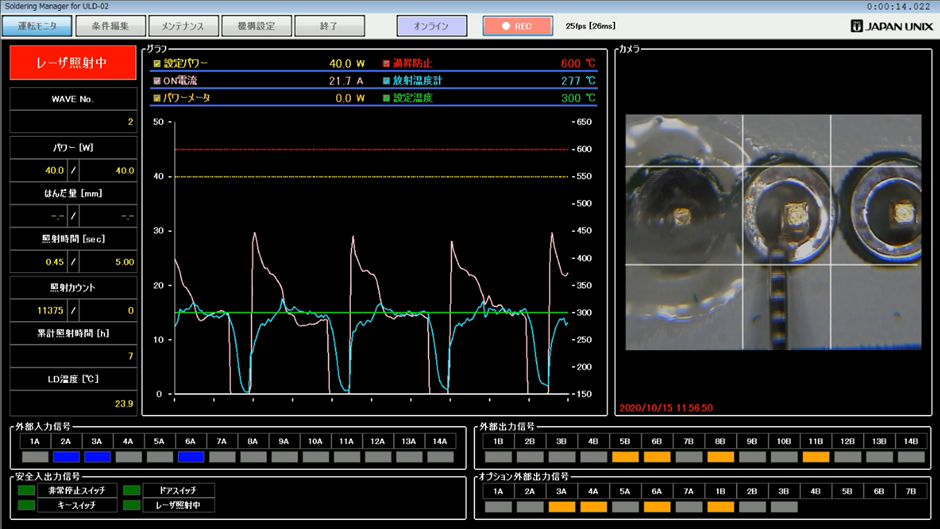

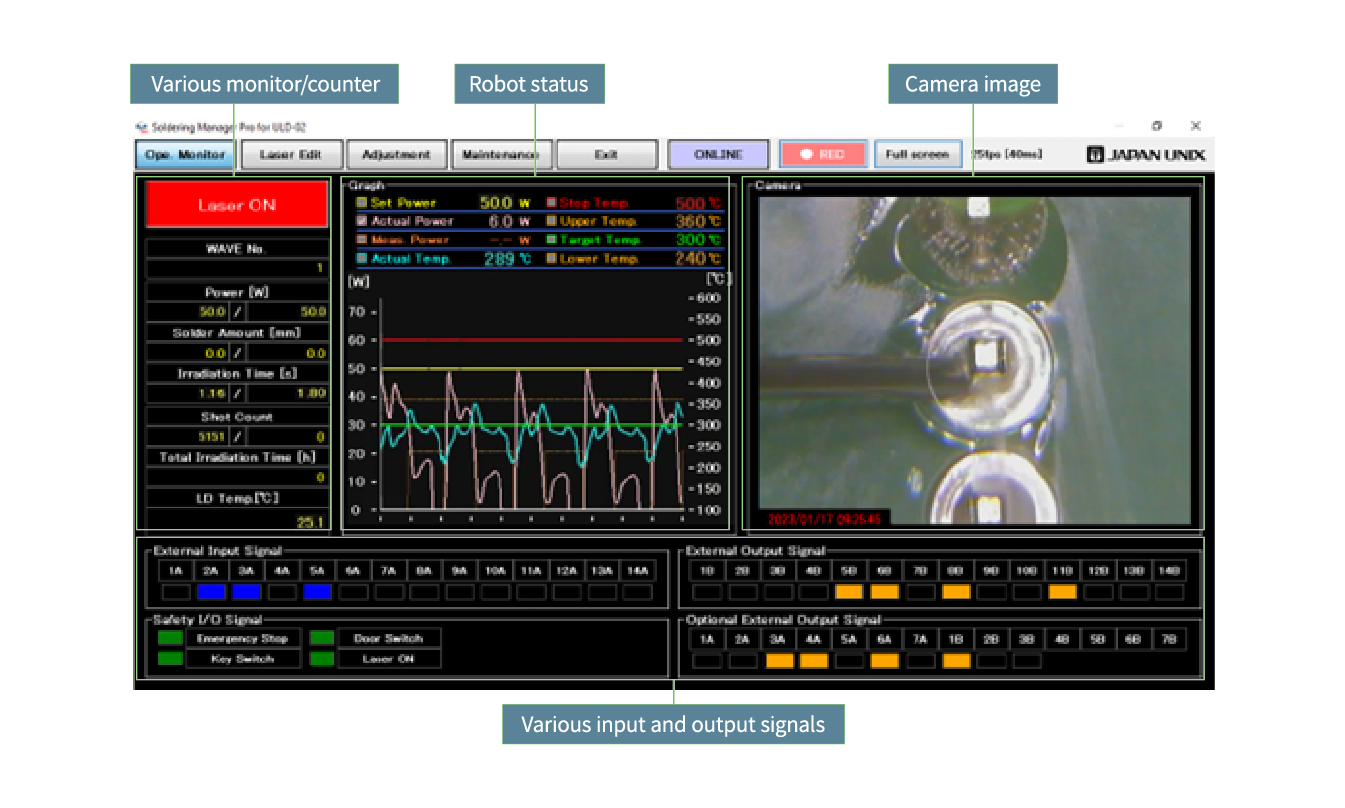

Soldering Manager (for laser)

- Visualization and recording of information such as laser output, output time, and solder amount (during internal control) for each point

- Laser output is converted to current value.

- Enhanced traceability through video and data recording during soldering

- Global process control is possible by sharing acquired data. When used in conjunction with Thermo ProTM (a temperature control function), the following information can also be managed:

- Soldering temperature

- Control over target temperature

- Over-temperature function alarms and stops in case of abnormality

- Primary good/fail judgment by temperature band function

ULD-02

Requirement for system configuration

| OS | Windows® 10/11 *64 bit only |

| CPU | Intel® Core™ i5 or more |

| Memory | 8GB or more |

| Resolution | WXGA(1366×768) or lower [Recommended:1280×720] |

| Free disk space on HDD | 500GB or more |

| Interface | USBポート USB3.0 Type-A |

Standard Configuration

Soldering Manager

- Software

- USB dongle, various cables, etc.

Option

Camera set

- USB Camera

- Video Capture

- Various Cables

Bracket

- Bracket for Iron Tip Camera

Reference Videos

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español