Let's Try Soldering! Narrow Pitch - Hall ICs by Tip and Laser

Automation Case Study: YouTube Article

Let’s Try Soldering Series: Soldering Hall ICs

Table of Contents

- Introduction

- Tip Soldering

- Laser Soldering

- Conclusion

- Related Products & Services

- Watch the Video for This Article

Watch the Video for This Article Here

Where Is Automatic Soldering of Hall ICs Used?

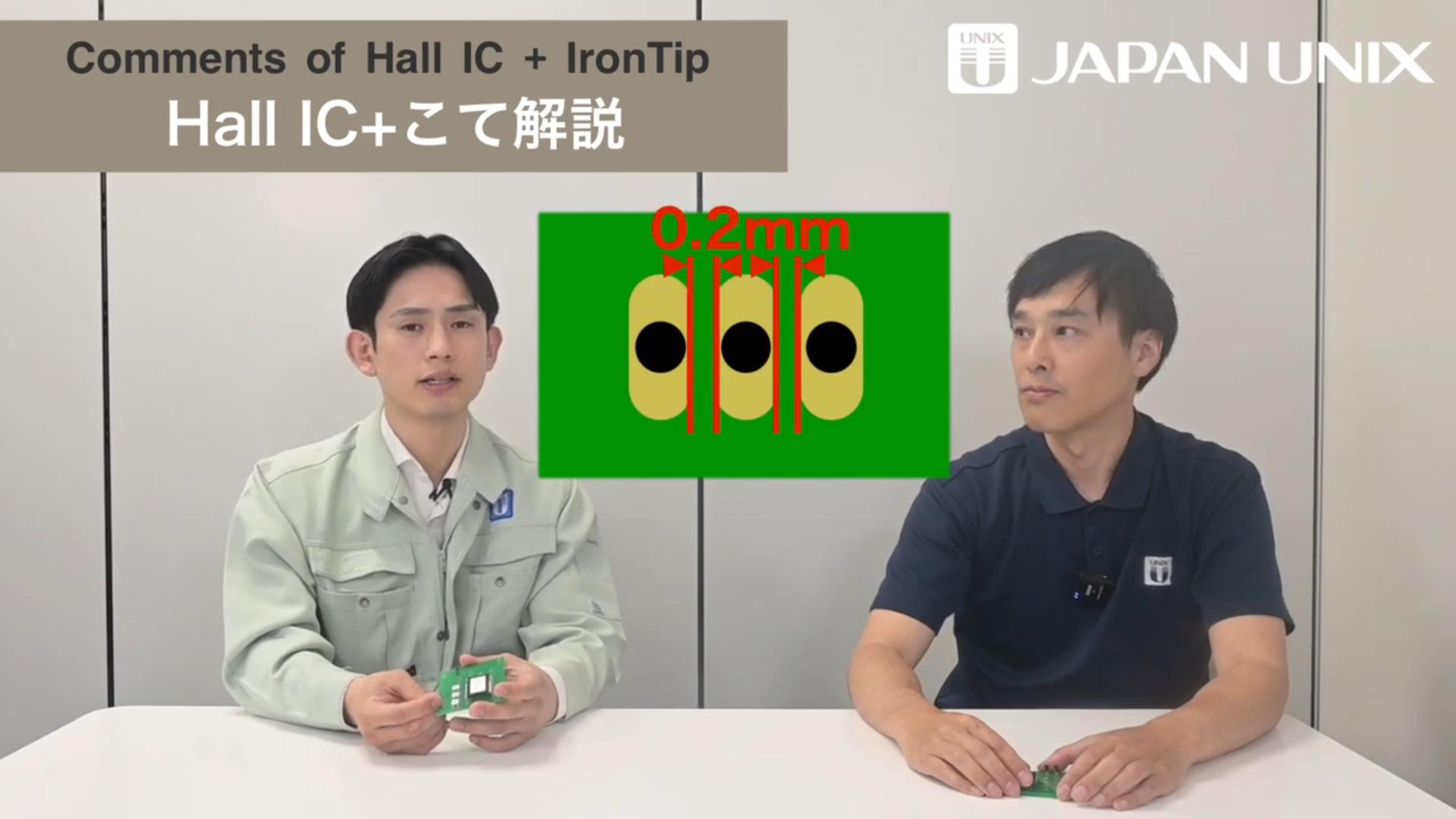

Naka Hello everyone, this is Nakano from Japan Unix.

In today’s “Let’s Try Soldering” series, the theme is Hall IC soldering. Our guest today is Engineer Yanaka. Thank you for joining us.

Could you tell us where Hall ICs are typically used?

Yana Hall ICs are sensors that detect position and rotation. In automotive parts, they are used for detecting pedal positions and steering rotation angles.

Naka It’s a very important component now that driving assistance technologies are becoming widespread.

Yana Exactly.

Tip Soldering for Hall ICs

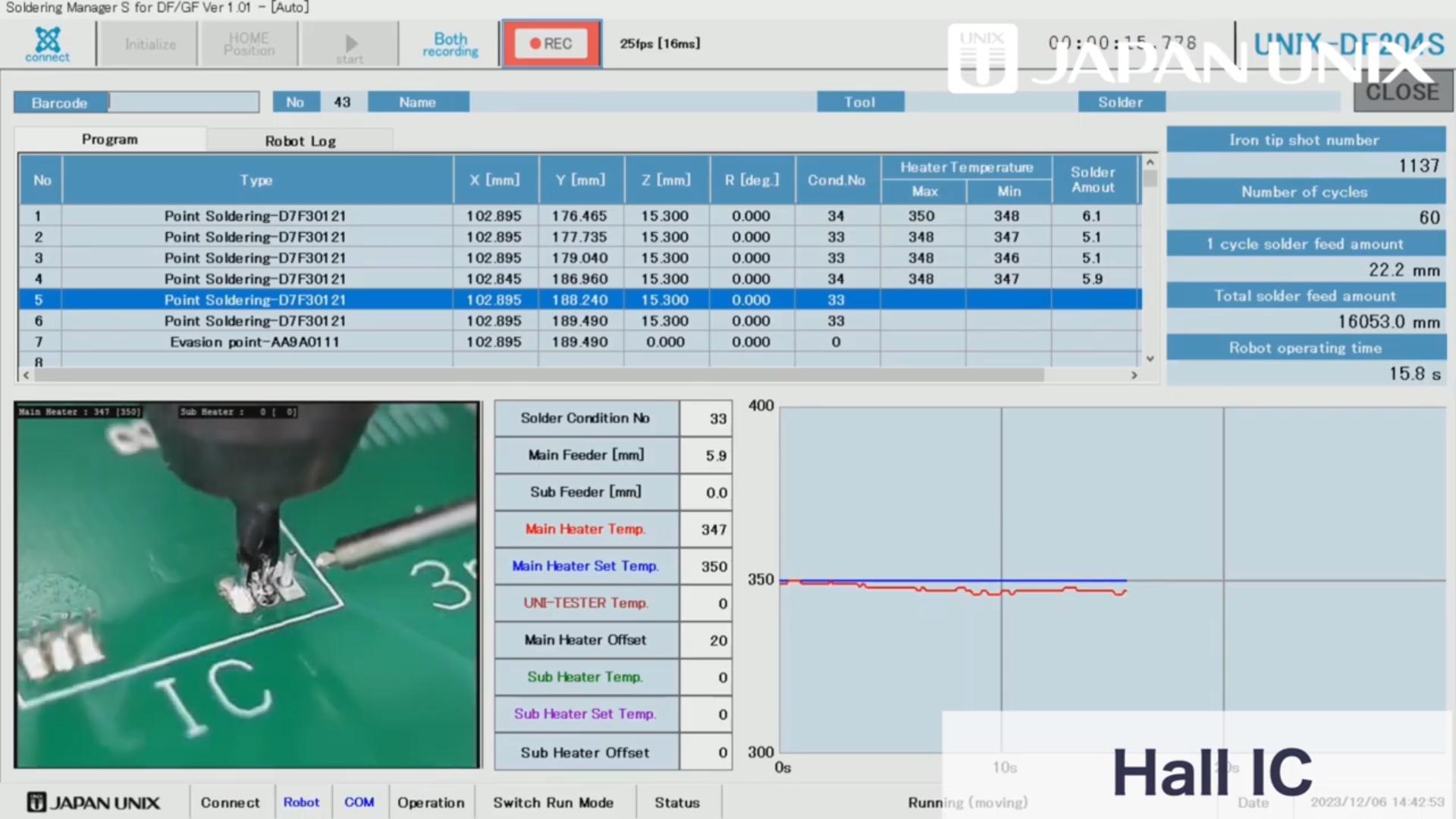

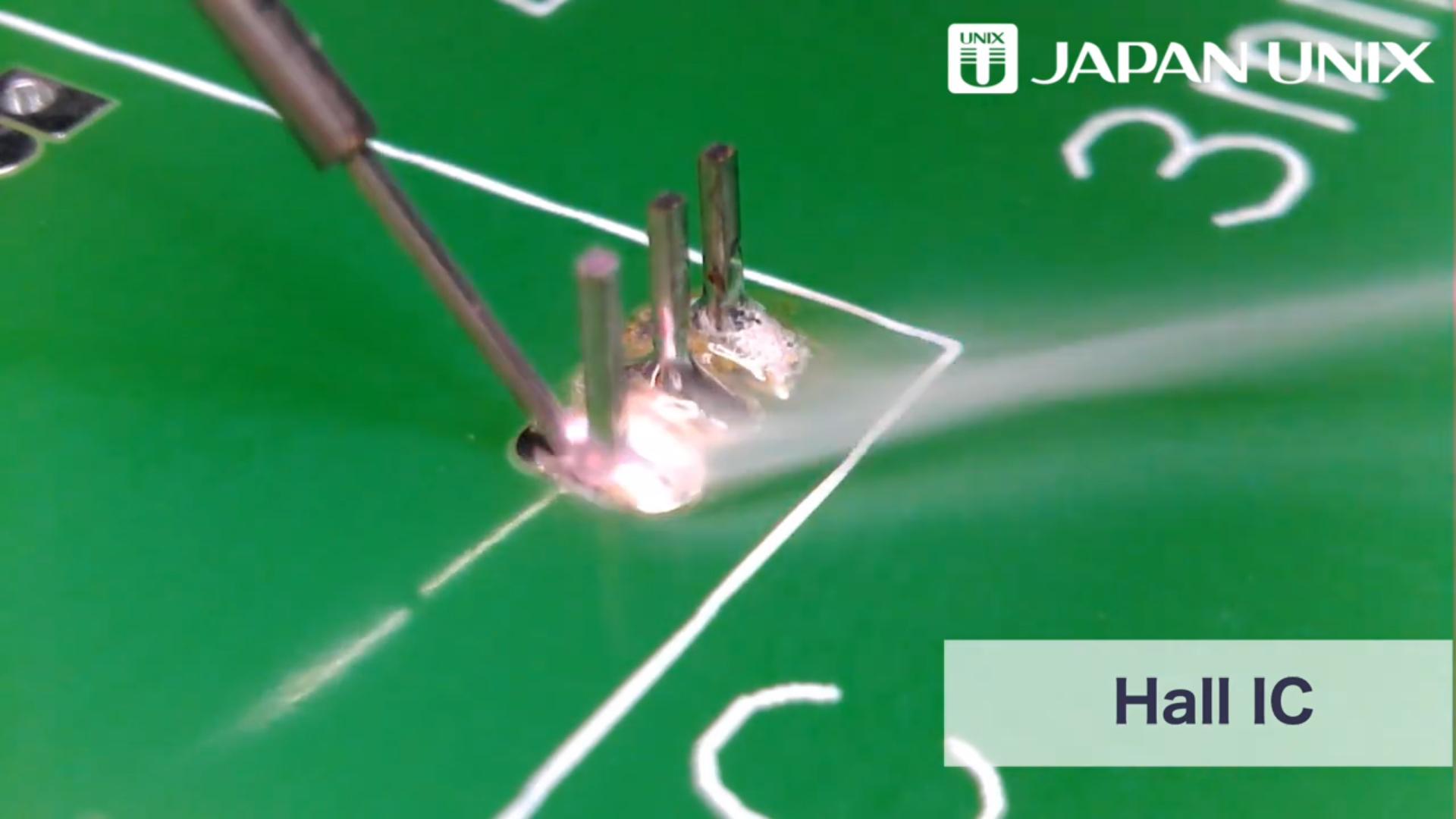

Yana Now, we have a video of tip soldering. Please have a look.

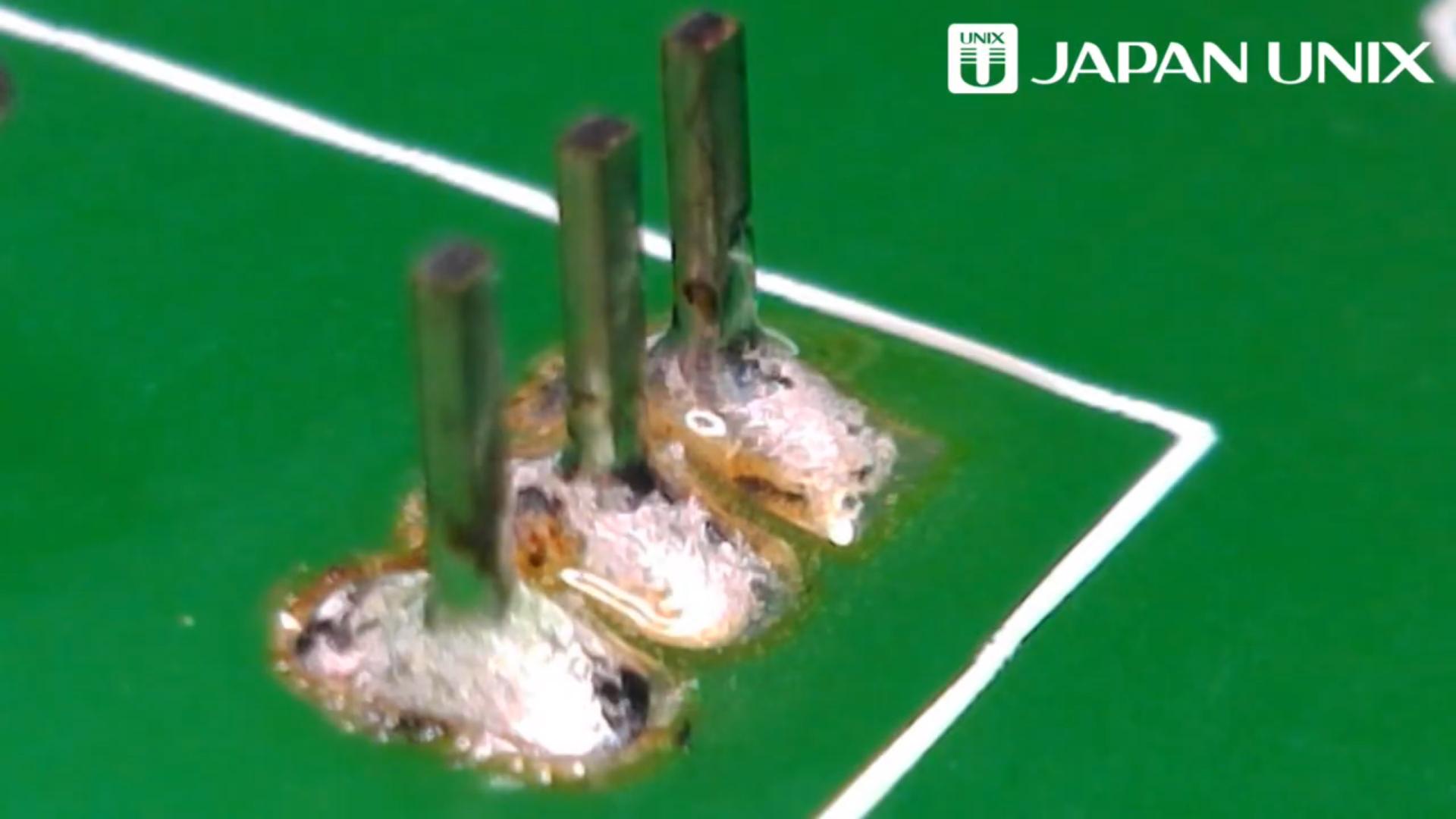

Naka This is the actual product after soldering.

Despite the narrow pitch, it was soldered without any bridging. Could you tell us about the important points and characteristics when soldering Hall ICs?

Yana The biggest feature of insertion-type Hall ICs is that the distance between PCB pads is only 0.2 mm, making it very prone to bridging. Therefore, not only the soldering tip but also the accuracy of solder supply is extremely important.

Naka So, the reproducibility of positioning and maintenance of the tip condition are crucial.

Yana Also, with Hall ICs, not only the soldering equipment side but also the positional accuracy of the component is very important.

If the height and position are not accurate, it will result in defective products.

Naka It seems necessary to consider precise jigs and, if using a robotic arm, accurate holding of components as well.

Yana Exactly.

Laser Soldering for Hall ICs

Naka Next, let’s take a look at laser soldering. Here it is.

This is the product soldered using a laser. It was also soldered beautifully without any bridging.

Please tell us about the important points and characteristics of laser soldering as well.

Yana One feature of laser soldering is that it can heat only the desired area, making it less likely for solder to bridge to neighboring pads. It is very advantageous for soldering narrow pitches and small patterns.

Naka So it offers high reproducibility of positioning and heating.

Yana However, if the terminal is overheated, since the terminals are thin, the heat may transfer to the component itself, causing damage.

Naka So in laser soldering, temperature control is extremely important.

Yana Exactly.

Conclusion

Naka Thank you very much for today, Mr. Yanaka.

Yana Thank you very much.

Naka See you again in the next video.

See you next time!

Related Products & Services

Watch the Video for This Article

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español