What causes solder balls? Explanation of Causes and Countermeasures by Soldering Robot [YouTube Tech Article]

YOUTUBE Tech Article

What causes solder balls? Explaining the causes and countermeasures with soldering robots

Table of Contents

- Theme

- Factor 1: During Contact

- Factor 2: While feeding Solder

- Factor 3: Moisture in the PCB

- Summary

- Related Products & Services

- Watch this article’s video here

Watch this article’s video here

Theme

U Hello everyone. Supporting your soldering life, I’m Unokuchi.

Today, I’d like to talk about a soldering defect that we get a lot of inquiries about, which is solder balls. There are different reasons and ways solder balls occur. Today, we won’t discuss the method of heating the entire object but focus on the selective heating method that JapanUnix frequently uses.

There are several causes for the occurrence of solder balls, but today I’d like to mention the three most common causes I often hear about.

Factor 1: During Contact

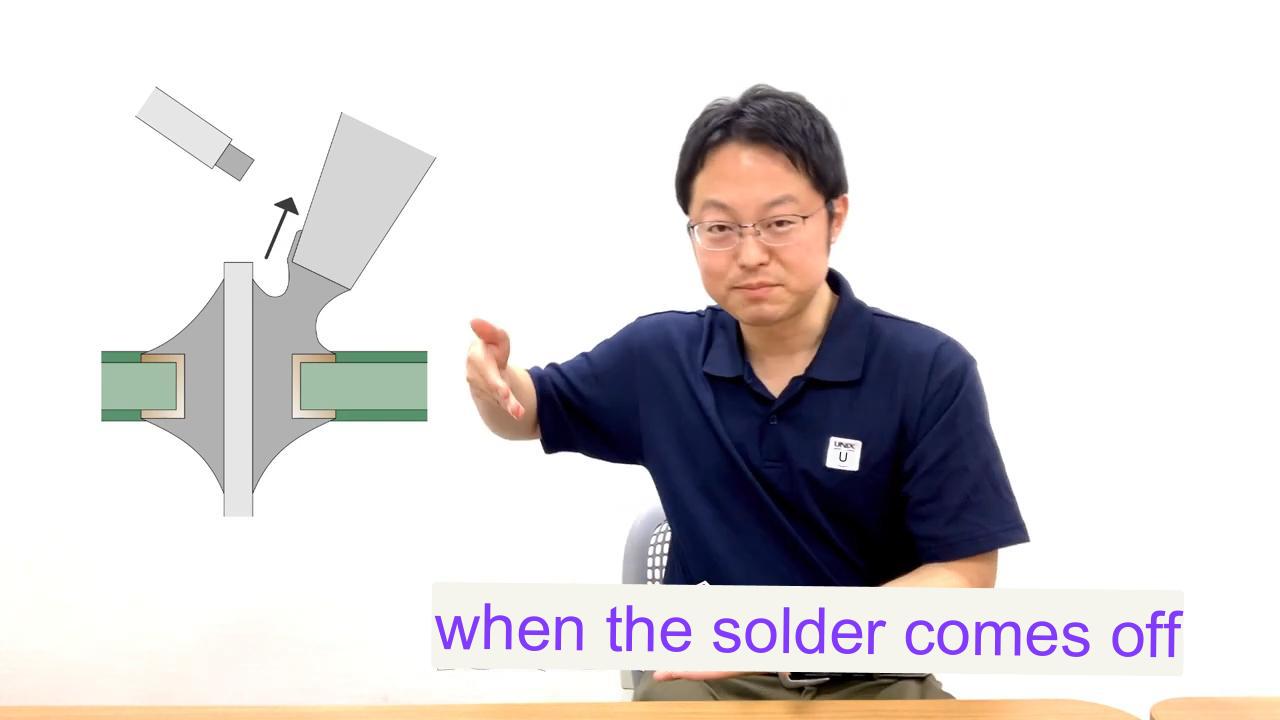

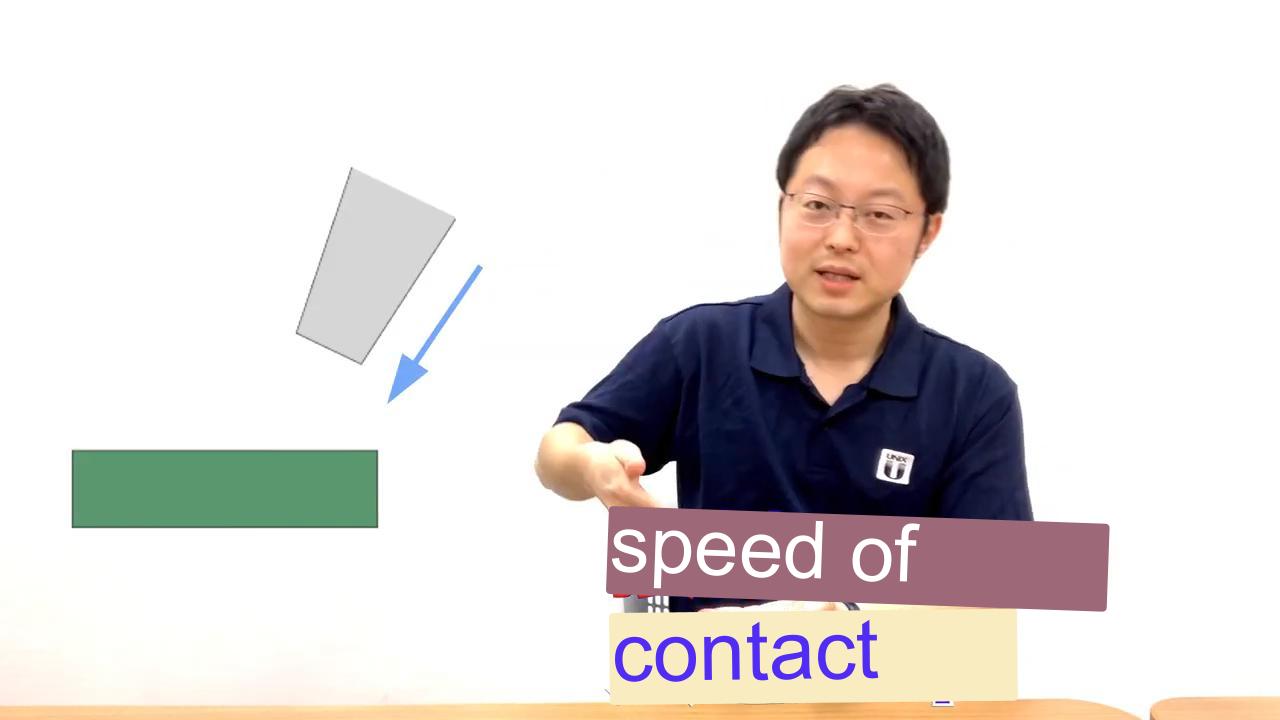

U The first cause of solder balls is during contact. They occur when the heating element contacts the object and when it detaches. Why does this happen? Solder balls are attached to the heating source and drop off upon contact. This is one of the main reasons.

Also, the solder already present on the heating element, this solder detaches when separated.

In this way, they occur due to contact. This is one of the major causes.

U To mitigate this issue, make sure there are no extra materials attached during contact, so it’s crucial to clean thoroughly and manage the objects in a temperature-controlled environment. Another method is to reduce the time of contact, ensuring it’s only enough to transfer the necessary amount of heat. This can help in reducing the occurrence of solder balls.

Factor 2: when feeding solder

U Next, the cause of solder ball formation, factor 2.

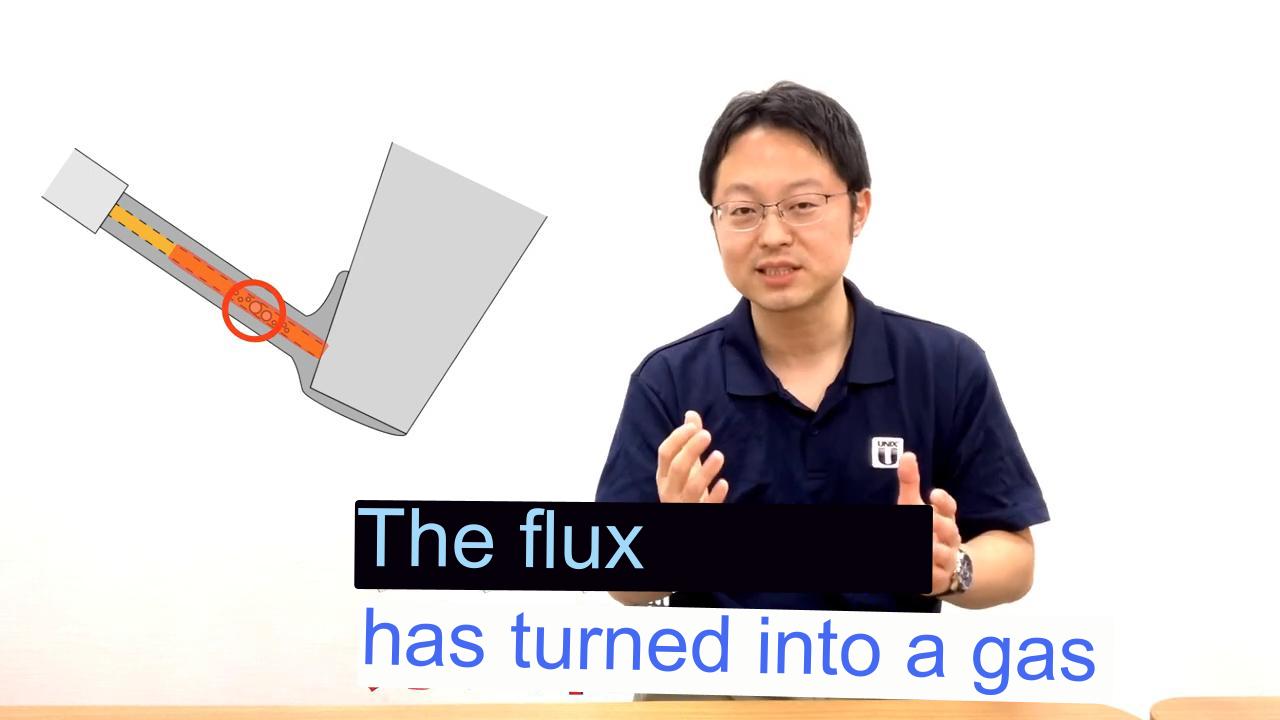

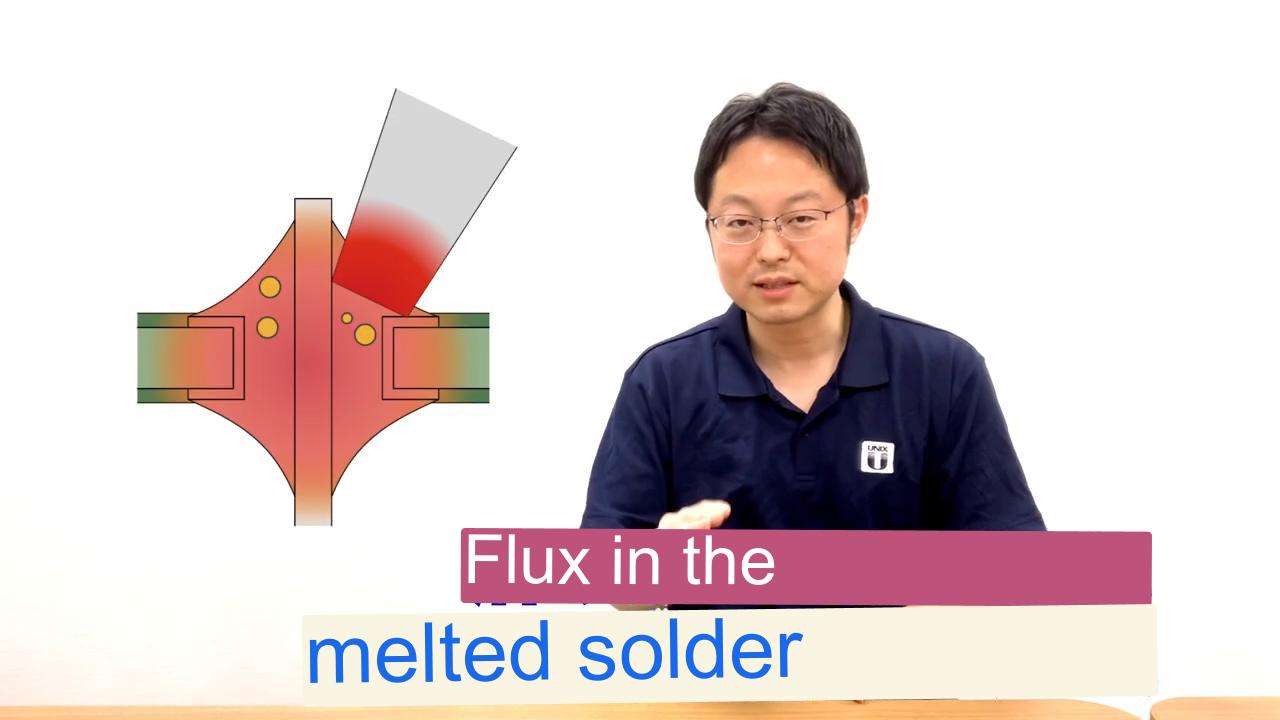

When solder is fed, it occurs at that timing. Especially, it occurs when the speed of solder feeding is either too fast or too slow, due to the flux contained in the wire solder.

In the case of it being too fast, the flux vaporizes due to a rapid temperature rise and adheres to the surroundings in a popping manner. If it’s too slow, the solder is overheated, causing the flux inside to vaporize and pop.

This can be caused by the flux contained in the solder during feeding.

U For this situation, the countermeasure is to adjust the speed of solder feeding to an appropriate speed. There’s a just-right speed, so discern it.

Also, by making notches in the solder itself, it’s harder for the internal flux to vaporize. Please consider these countermeasures.

Factor 3: moisture inside the board

U Lastly, the cause of solder ball formation, factor 3.

Moisture trapped inside the board. This is a cause. We sometimes refer to it as humidity, but the moisture inside the board tries to escape when heated.

And when trying to escape, it pops out.

U As for the countermeasures, it’s not about the heating tools but more about condition management of the board or components.

For instance, seasonality, like the rainy season in June, can make boards more humid. Therefore, it’s crucial to dry them properly and solder in that condition.

Conclusion

U In summary, there are various factors that can cause solder ball formation. It’s crucial to grasp the cause properly and take countermeasures.

Soldering is not just about the solder and the tool, but also about the surrounding conditions. Always be mindful of them.

Related Products & Services

The video for this article is here

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español