Soldering Unit

Soldering heads for contact, Feeders, Controllers and Cleaners

Customers can choose some of our soldering units. There are some basic combinations in order to install automated soldering on the existing machines. A soldering head, a solder feeder and a contoroller are necessary for contact soldering. Laser soldering will need a solder feeder and a controller. In the case of ultrasonic soldering, a soldering head and a solder feeder must be added on. Cleaners will extend tip life and will enhance output quality due to the elimination of impurities.

*Some combinations are not possible depending on the unit.

*Some options are not supported by some units.

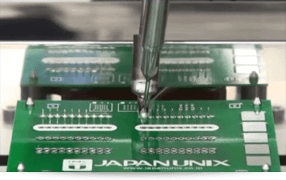

SOLDERING HEADS

Soldering head (standard)UMC-087B

- Easy to maintenance (soldering tip, heater)

- Shock absorbing mechanism

- Press-down soldering is possible

- Angle set with memory

- FR series, D304,404S standard specification

Soldering head (compact)UMC-086S

- Small & lightweight

- Shock absorbing mechanism

- Press-down soldering is possible

- DF204S optional equipment

SOLDER FEEDER

CONTROLLERS

Soldering controller

USC-881/881S

- Developed for automatic soldering

- Monitoring the tip temp.

- Easy operation

- 2,032 conditions

- 410R Standard specification

TIP CLEANERS

Air blow type cleaner

UJC-214II

- Air blower, vacuum type

- Reduces debris scattering

- Built-in solenoid valve

- 410S/R, 700 Series standard specification

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español