What is the importance of optimum conditions in laser soldering? [YouTube Tech Article]

YOUTUBE Tech Article Part 5!

The Importance of Optimal Conditions in Laser Soldering

Table of Contents

- Theme

- Key Points in Laser Soldering

- Soldering Video

- Summary

- Related Products & Services

- Video for This Column

Video for This Column

Theme

unokuchi Hello everyone, it’s Unokuchi, supporting your soldering life.

Today, I have previously showcased several videos about lasers, but today, as a sequel, I would like to convey the key points for successful laser soldering.

Key Points in Laser Soldering

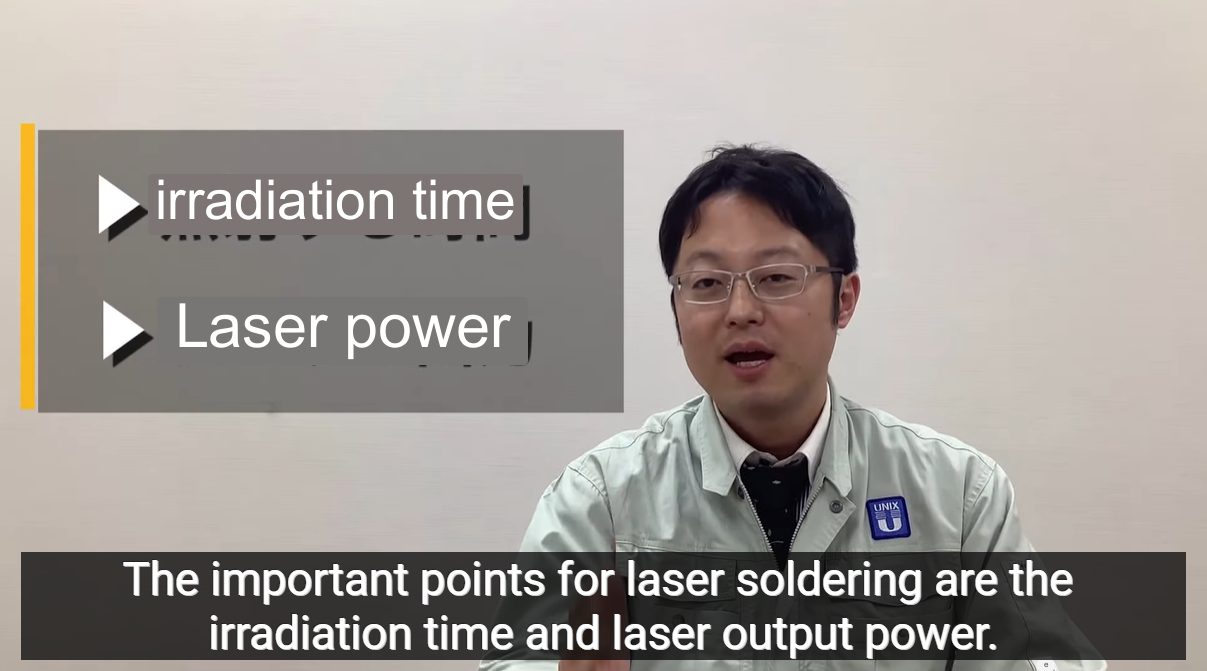

unokuchi The key in laser soldering is the duration of laser exposure and the output, power of the laser.

Identifying these correctly and checking if the component or board is being adequately heated to the solder’s melting point is essential. The output and timing. Pinpointing these is the most critical point.

We’ve filmed a video soldering under various conditions focusing on these points, so let’s watch it together.

Here’s the translation of the provided text into English:

“`html

Video Commentary

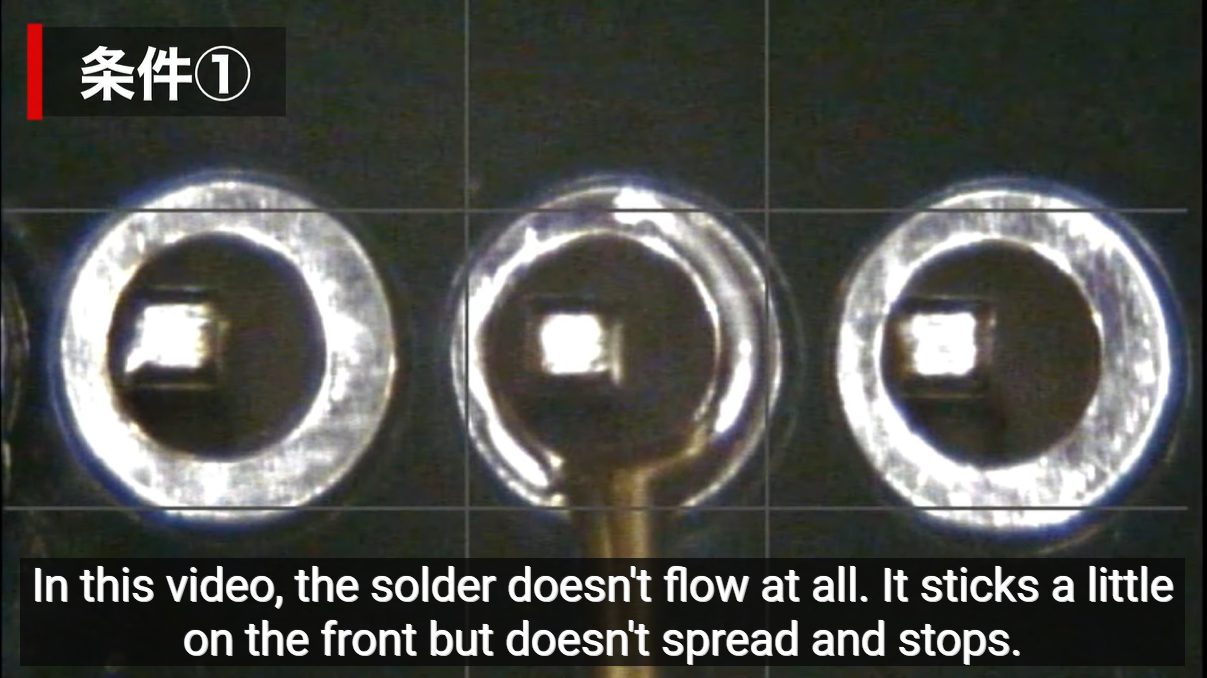

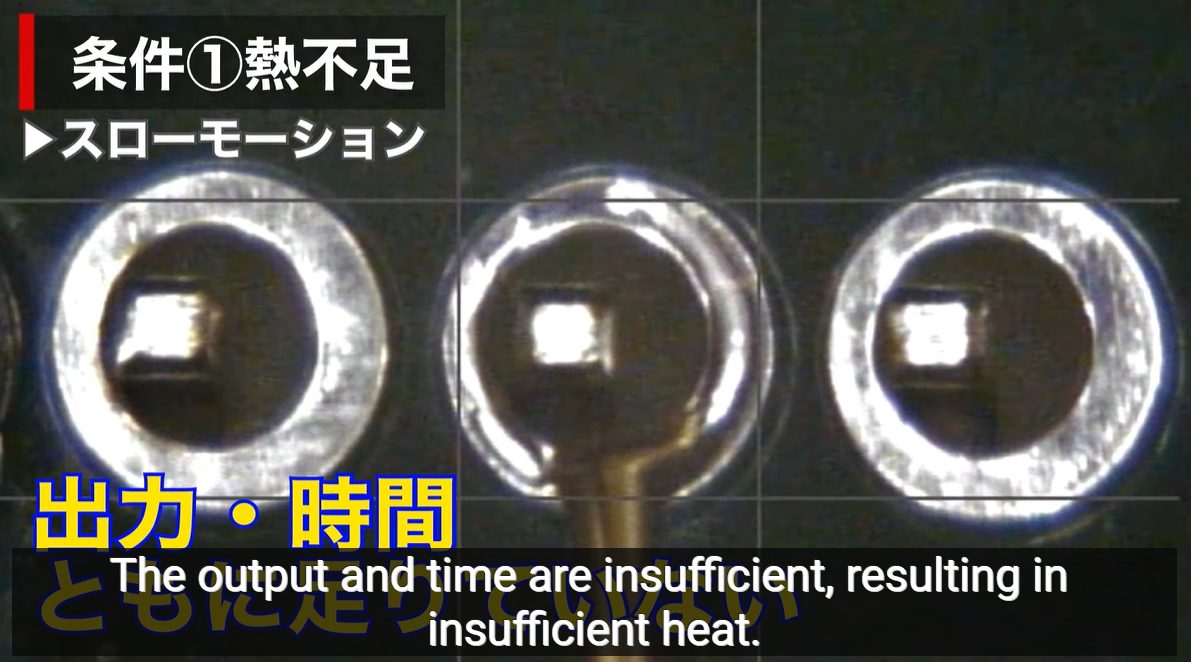

U This is the first soldering video. In this video, the solder doesn’t circulate at all, and it only slightly attaches at the front, then stops without spreading. This is clearly a situation where both the output and duration are insufficient, and there’s not enough heat.

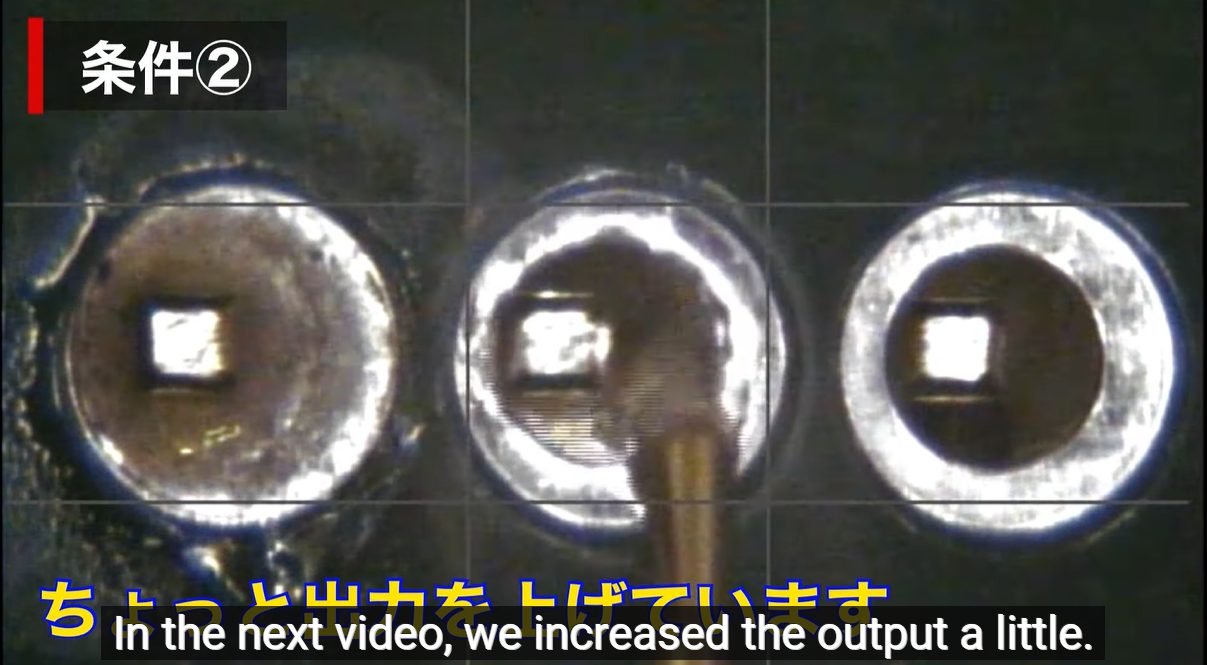

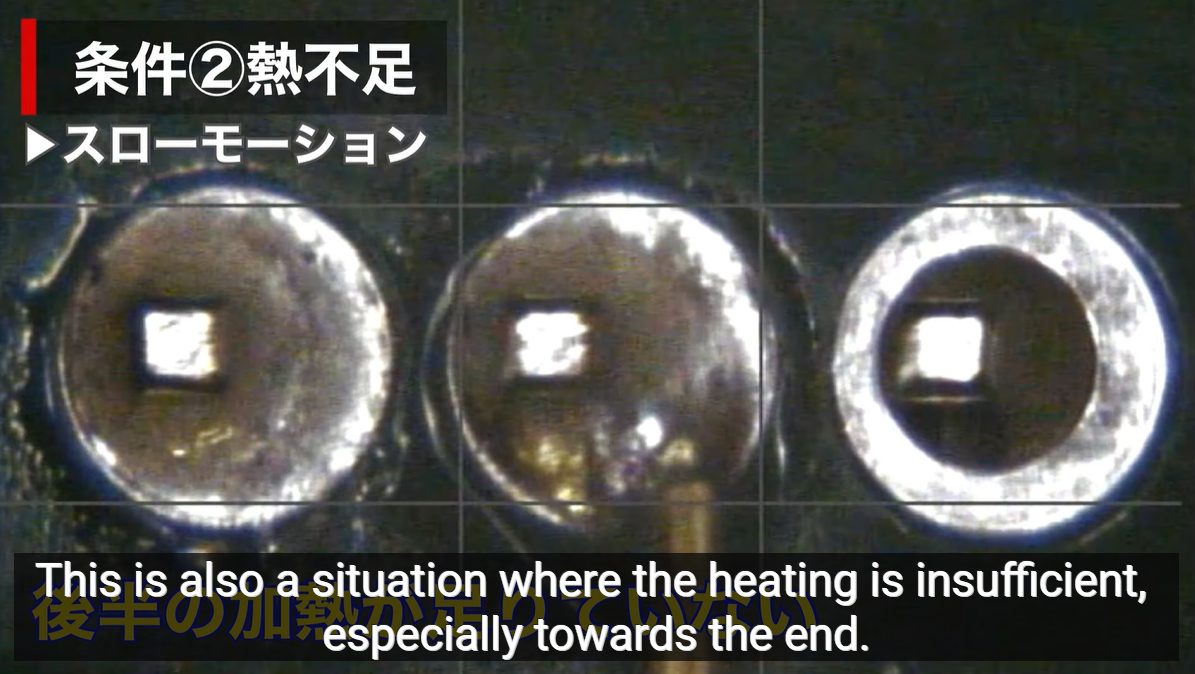

U Next, we increased the output for the following video. It looked like it melted well, but in the end, the solder did not fully melt, and remained in a state where the solder wire was attached to the melted solder. This is also due to insufficient heating in the latter half. It’s still not heated enough.

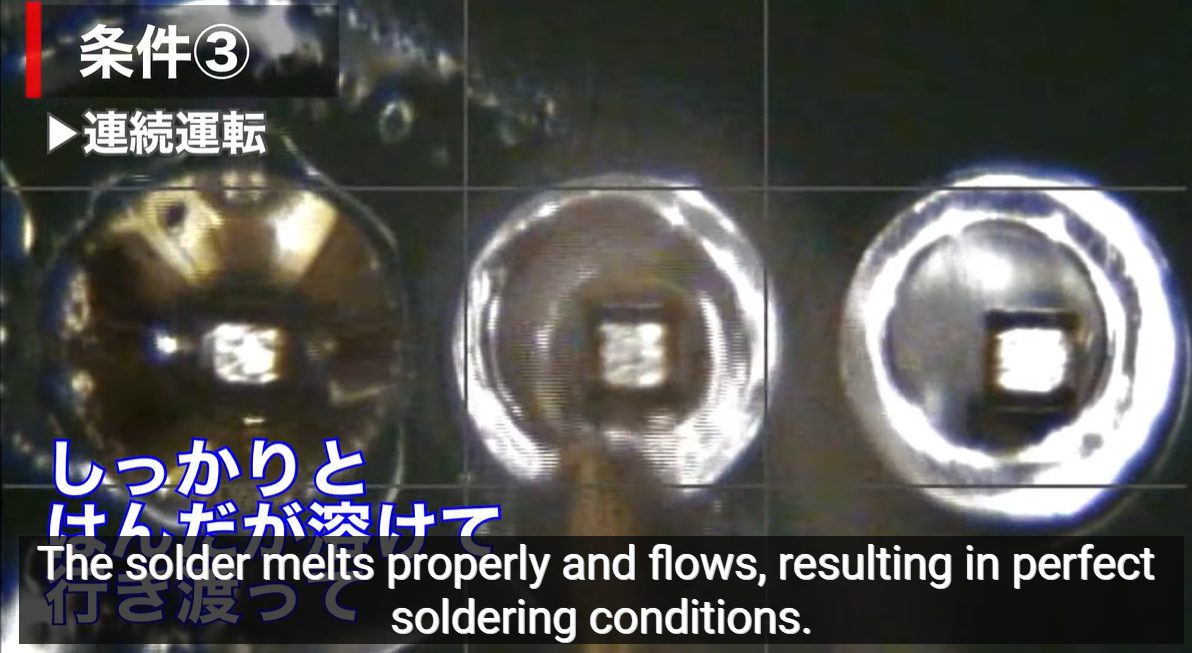

U Next, we are almost there, just one more step. This time, we extended the heating time a little more. This was done continuously. The solder melted and spread thoroughly, achieving perfect soldering conditions.

Summary

Note What we looked at now focused primarily on points where the output and time seemed a little insufficient. On the contrary, if you put too much output, too much power, or spend too much time, you can damage the circuit board or components through overheating. Therefore, what’s crucial is setting the right balance in laser output and time—neither too little nor too much—to find the optimal conditions. This is critically important.

To find these optimal conditions, you need to follow the principles of soldering and adjust the laser accordingly. Thus, for customers considering automating soldering with various lasers, we highly recommend conducting experiments to determine the best conditions.

Note At Japan Unix, we conduct such laser soldering experiments regularly. If you want to give it a try or just want to see how it behaves, please don’t hesitate to contact us.

See you again soon.

Related Products & Services

Check out the video for this column

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español