"A MUST-SEE for beginners!" Basic Configuration and Automation Process of Soldering Robot [YouTube Tech Article]

YOUTUBE Column!

“A MUST-SEE for beginners!” Basic Configuration and Automation Process of Soldering Robot

Table of Contents

- Theme

- Soldering Head

- Solder Feeding

- Cleaning

- Teaching

- Related Products & Services

- Video of This Column

Video of This Column

Theme

U Hello everyone, I am Unokuchi, here to support your soldering life. Today, we have Mr. Yamanashi from SE with us.

Many people are interested in automating their hand-soldering process with soldering robots. Today, with the help of SE’s Mr. Yamanashi, we will explain the components and configuration of these soldering functions in robots.

Thank you, Mr. Yamanashi, for joining us.

Yama Thank you, I’m glad to be here.

Soldering Head

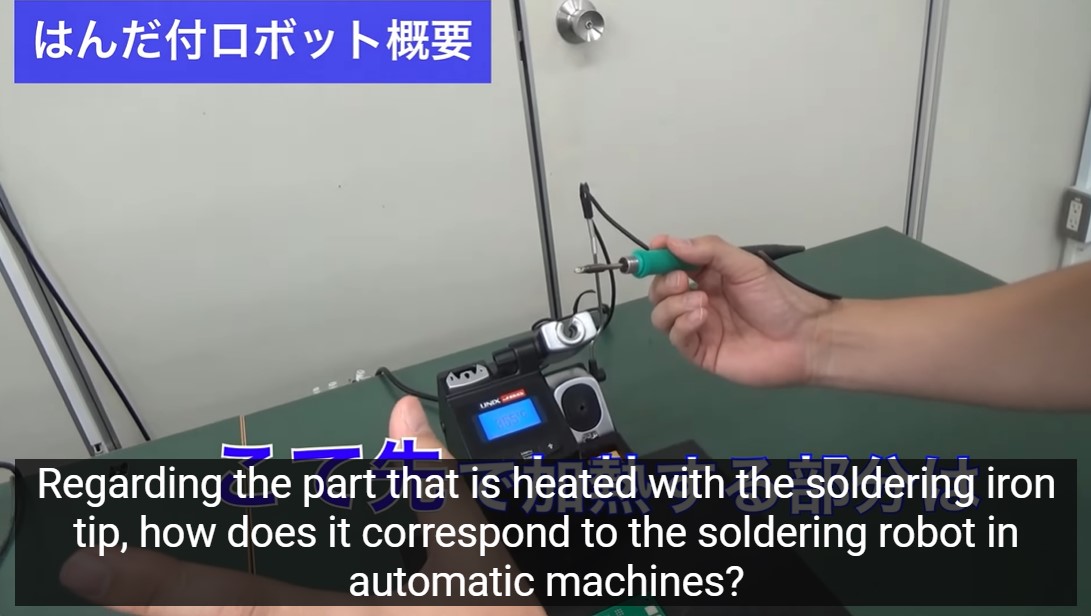

U Firstly, let’s talk about the soldering work in hand soldering. This involves a soldering iron, but what part of the automated soldering robot corresponds to the part of the iron that heats up in hand soldering?

Yama That would be what is called the soldering head in the robot, where the tip is heated to perform the soldering.

U So, when we attach the hand soldering iron to the robot, it becomes the soldering head. Are there any unique features of the soldering head in automated machines?

Yama Yes, first of all, the angle of the iron tip can be fixed, and the solder supply also can be fixed at different angles.

Solder Feeding

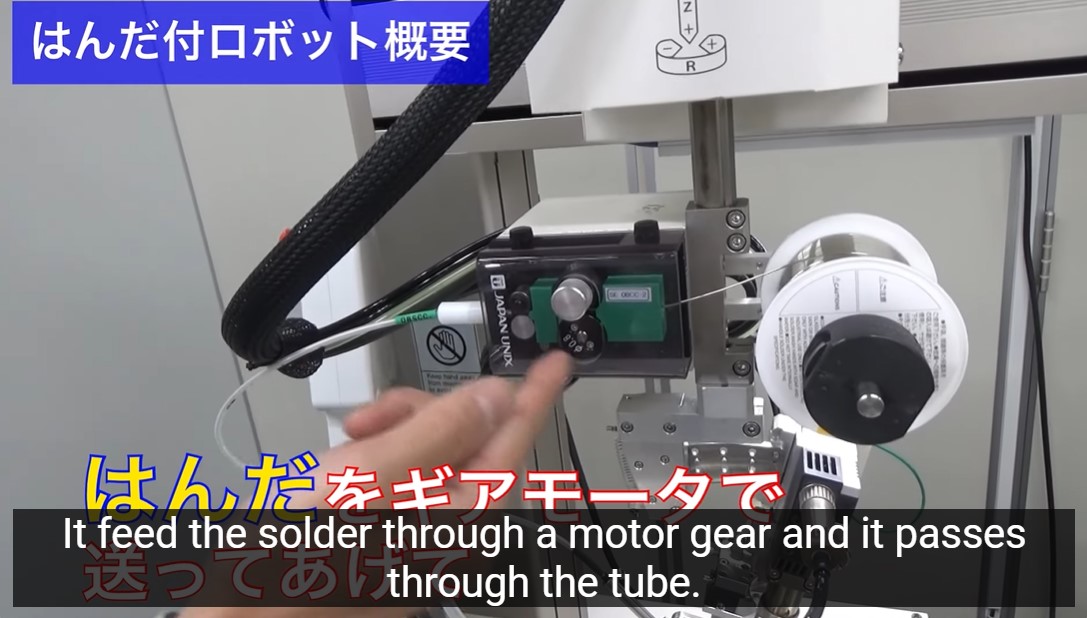

U Next is solder supply, solder feeding. I believe heating and solder feeding go hand in hand, but what part replaces hand solder feeding in automated machines?

Yama Yes, it’s this part here, the solder feeder, which uses a motor to feed the solder through a tube, and then through a part called the needle. From the tip of the needle, solder is supplied.

Cleaning

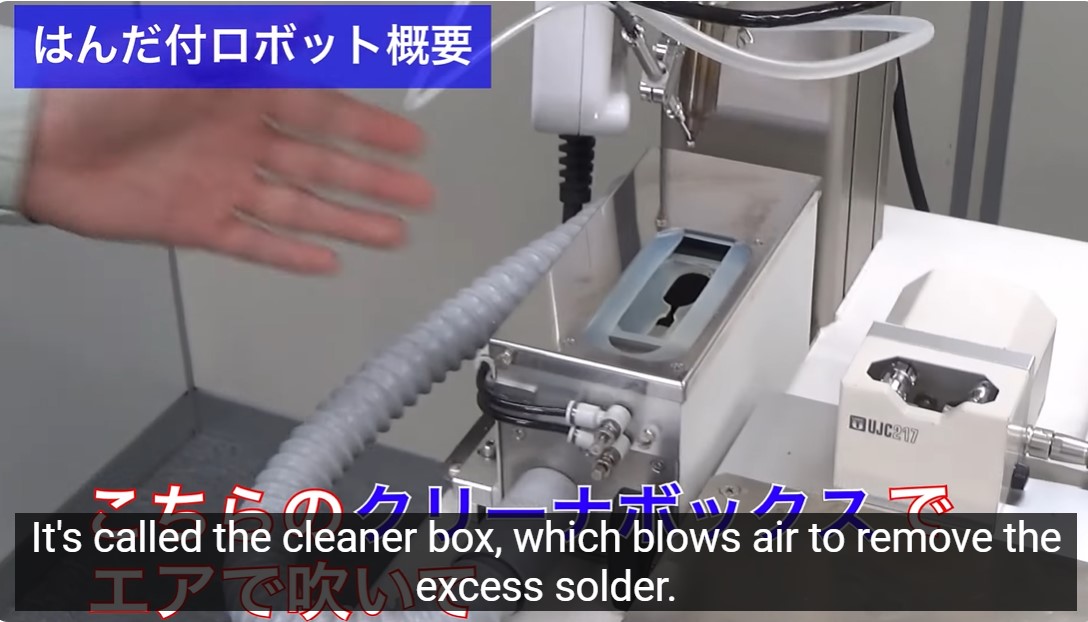

U Next, we discuss cleaning the excess solder that accumulates on the iron tip during soldering. Where is this function located in the robot?

Yama This function is handled by what’s called the Cleaner Box, which uses air to blow away the excess solder.

U An air cleaner?

Yama Yes, that’s right.

U In previous videos, you mentioned about carbides getting attached. Can this cleaner remove them?

Yama Air alone can’t clean everything. For that, we have another option, the Brush Cleaner, which removes the carbides.

U So, the air cleaner is for removing excess solder, while the brush cleaner takes care of the tougher dirt.

Yama Exactly.

Teaching

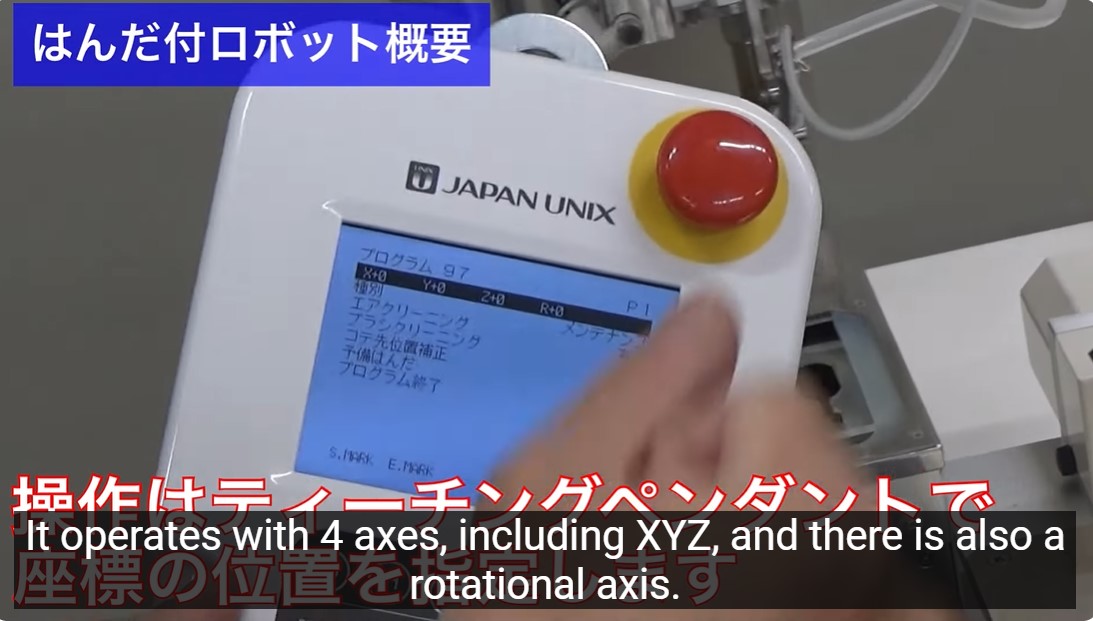

U In hand soldering, a person moves the iron to the correct positionrobot, which moves along four axes. The positioning is controlled using this teaching pendant, where we specify the coordinates to ensure the accuracy of the position.

The coordinates include XYZ and a rotation axis.

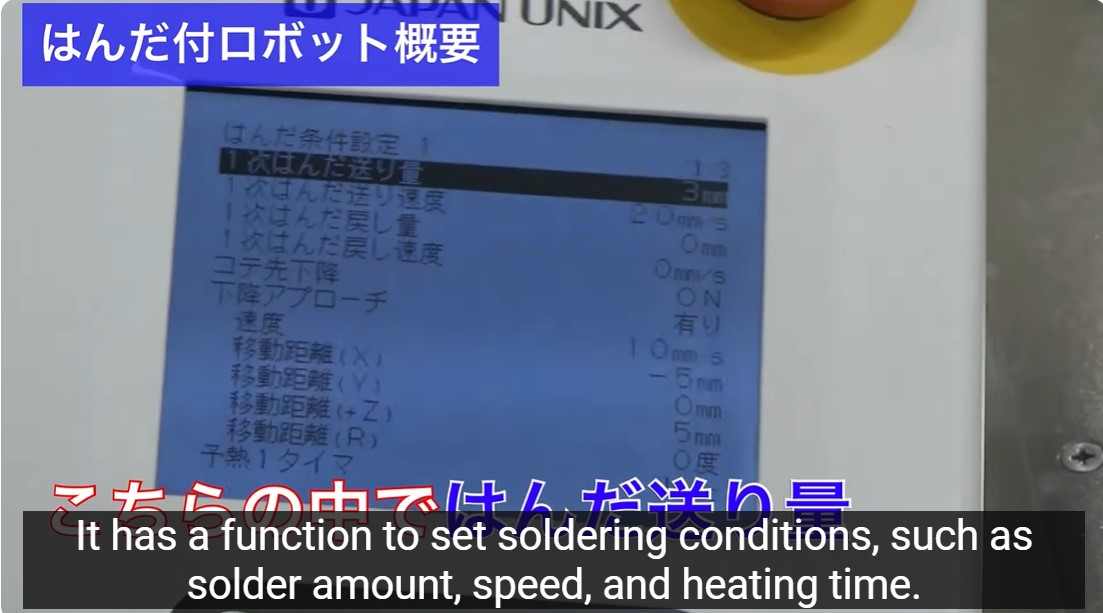

U Finally, soldering inevitably involves factors like the time taken to heat, the amount of solder fed, and the speed of soldering. I guess this is where the expertise and skill of experienced workers come into play. How are these aspects programmed or recalled in a robot?

Yama Yes, these are set in the teaching pendant under solder conditions. Here, we set conditions such as the amount of solder, its speed, and the pre-heating wait time.

U So, can you input soldering know-how directly into it?

Yama Yes, that’s right.

U Thank you, Mr. Yamanashi, for sharing various insights about soldering robots today.

Yama You’re welcome, it was my pleasure.

U Let’s meet again next time.

Related Products & Services

Video of This Column

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español