Dual Area Laser Soldering System [Tech Webinar Transcription]

Webinar Column

Dual Area Laser Soldering System

Reading Time: About 3 minutes

Speaker: Shinichiro Kawakami

Sales Department, Overseas Sales Group, Manager

Introduction

Kawa I’m Shinichiro Kawakami from JAPANUNIX. This time, I would like to talk about the dual area laser. We have been selling laser soldering for over 20 years, and recently, the area laser has emerged and evolved into what we call the dual area.

What is this new “advanced area laser” like?

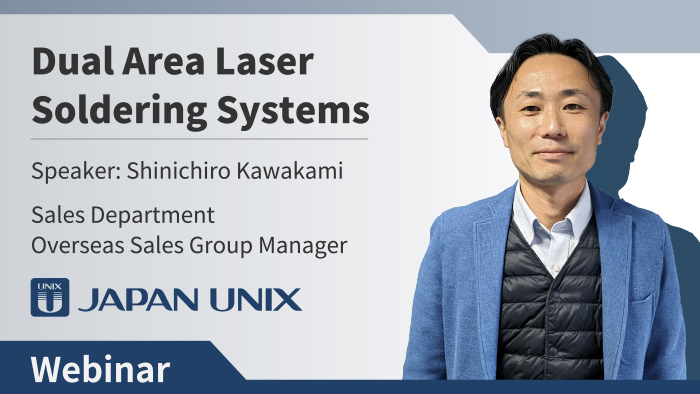

A single-spot laser is circular, with higher laser density at the center of the irradiation area. In contrast, an area laser can create shapes such as squares or rectangles, and its most significant feature is that the energy density of the irradiated area is uniform. This means that you can perform “multi-point soldering” simultaneously within this area.

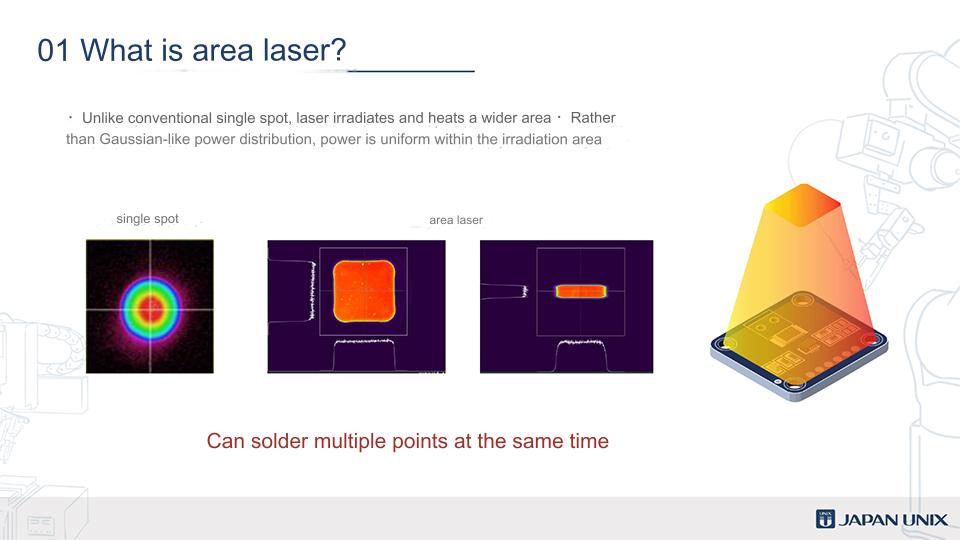

With the dual area, we have developed a system where robots are positioned above and below, and the area laser is irradiated from both top and bottom, enabling “simultaneous multi-point soldering” both above and below. This allows for more efficient soldering.

Advantages of Laser Soldering

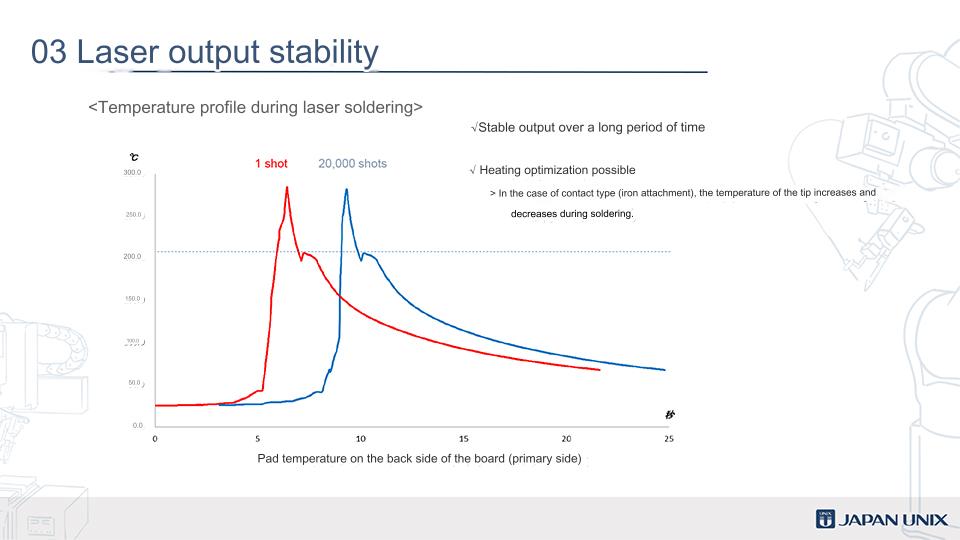

Stability of Laser Output

Kawa First, let’s look at the graph of laser output stability. This graph represents the temperature of the backside of the board, the primary side in IPC terminology. The red graph represents the first shot of the laser, while the blue line represents the temperature of the backside of the board at the 20,000th shot. The two graphs show almost the same temperature, indicating that the laser maintains stable temperature from the first shot to the 20,000th shot. This means that the laser, which is the heat source, is stable.

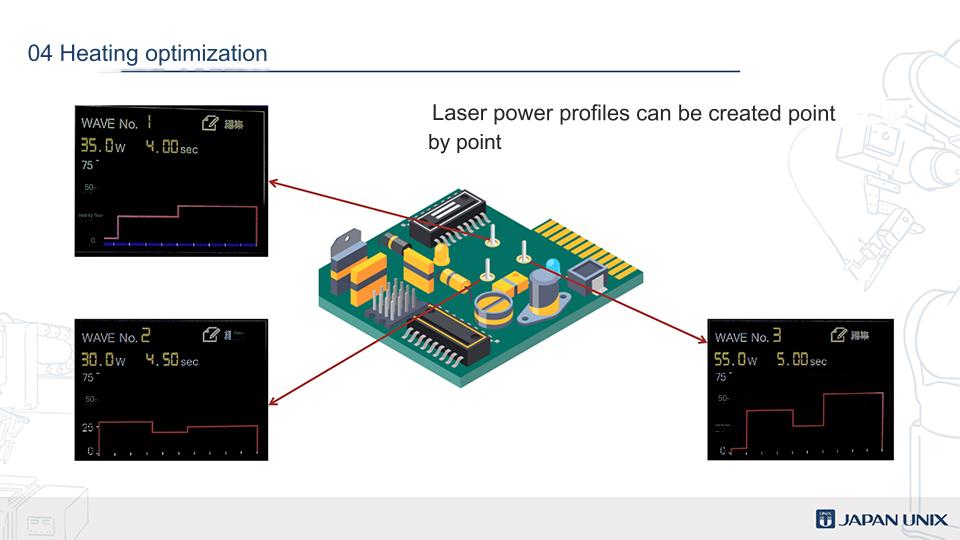

Optimization of Heating

Kawa Next is the optimization of heating. In other methods we have, such as soldering with a soldering iron or using a jet-type soldering from below, there are heat-carrying media like solder that has heat. For example, with a soldering iron, you can technically change the temperature for each point because it has heat of 350 degrees. However, if you want to raise or lower the temperature for the next point, you have to wait for a considerable amount of time. It is not practical to change the temperature for each point.

However, with laser, you can instantly change the output profile of the laser for each point. By creating an optimal laser profile for each point, you can achieve a more optimized heating condition. This is also a significant advantage of laser soldering.

Running Cost

Kawa Another factor is the running cost. In the case of laser soldering, you don’t need consumables like soldering iron heaters. On the other hand, tube sets and needles are commonly replaced by customers within 6 to 12 months. So, if we consider short-term consumables, laser soldering can be considered as having a cost of “0”.

130W LD (Laser Diode)

Kawa Now, we can accommodate a 130W LD. This applies not only to the main theme of this time, the area and dual area, but also to conventional single-spot lasers. With area lasers, even if you create a large area, the energy will disperse, but you can maintain a high heating capacity while making the area larger.

Although the capacity has increased with 130W, it is an air-cooled type, making maintenance very easy. If it were water-cooled, there are many high-capacity water-cooled types, but maintenance and upkeep become challenging.

Dual Area Laser

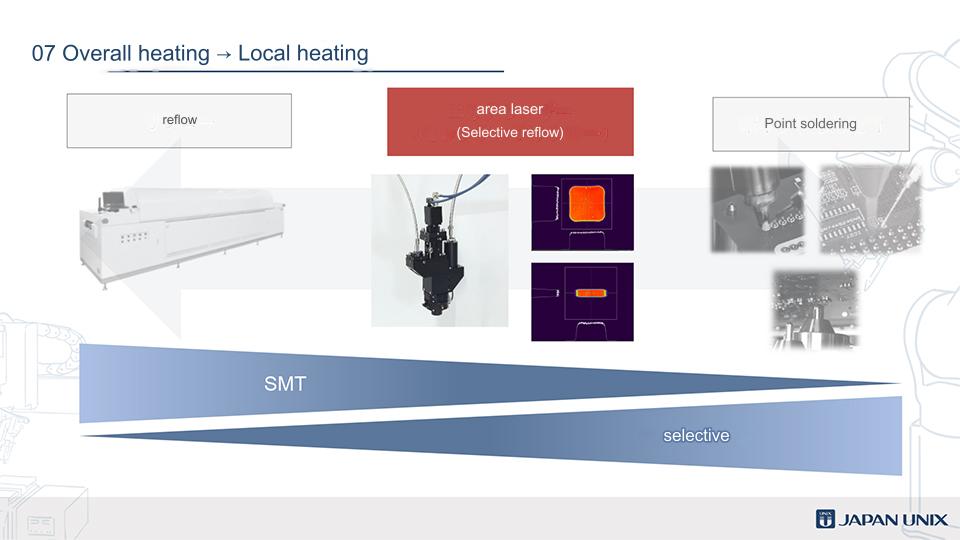

Selective SMT

Kawa In SMT, the common method used is reflow. This involves heating the entire board. After that, we have been doing what is called post-processing, which is point soldering, where we perform localized heating point by point. The area laser falls in between.

By heating a specific area while retaining the element of localized heating, the area laser can perform “multi-point soldering” for products with many points, such as SMT. You can think of it as “selective reflow” or “localized reflow”.

The biggest feature of reflow is that the cycle time remains constant, regardless of whether there are many or few SMT points. When it comes to the target area for the area laser, it provides significant advantages for areas with relatively fewer points where you want to perform some SMT.

Simultaneous Multi-Point Soldering

Kawa Now, let’s look at the concept of simultaneous multi-point soldering. With the dual area laser, the irradiation area of the laser is divided into two, and we can simultaneously heat both the top and bottom surfaces.

This allows for soldering on both sides at the same time, which leads to a significant improvement in efficiency.

Other Features

Kawa In addition to the simultaneous multi-point soldering, the dual area laser has several other features. For example, it has the capability of “dotting.” This means that instead of irradiating the laser in a continuous line, you can apply the laser in a dotted pattern, allowing for selective heating within the area.

Furthermore, by changing the power density, it is possible to create a temperature distribution within the area, which allows for more precise heating control.

Summary

Kawa Today, I introduced the dual area laser, which can perform “simultaneous multi-point soldering” both above and below. With this system, you can achieve more efficient soldering, leading to increased productivity and cost savings.

If you have any questions or would like more information, please feel free to contact us.

Related Products and Services

Please check out the following related products and services that support quality and maintenance of your mass production.

Related Videos for this Column

Contact Us

Kawa If you have any inquiries or would like to discuss your soldering needs, please feel free to contact us. Our team will be happy to assist you and provide the necessary information and support.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español