The Benefits of Laser Soldering [Steve's Tech Article]

Steve’s Tech Article!

The Benefits of Laser Soldering

Table of Contents

- Introduction

- Stable Quality

- Maintainability

- Running Cost

- Conclusion

- Related Products & Services

- Video of This Article

Here is the video for this article

Introduction

Steve Hello everyone, I’m Steve, a Soldering Engineer at Japan Unix.

Today, I’d like to talk about the benefits of laser soldering, a method that’s continuously evolving.

For over 20 years, Japan Unix has provided laser soldering robots to many customers.

I’d like to introduce the top three aspects our customers find especially appealing.

Stable Quality

Steve First and foremost, laser soldering maintains stable quality.

One of its key features is that it has minimal variables.

In other words, whether it’s the first or the 10,000th time, you get the same consistent soldering quality.

Why is that?

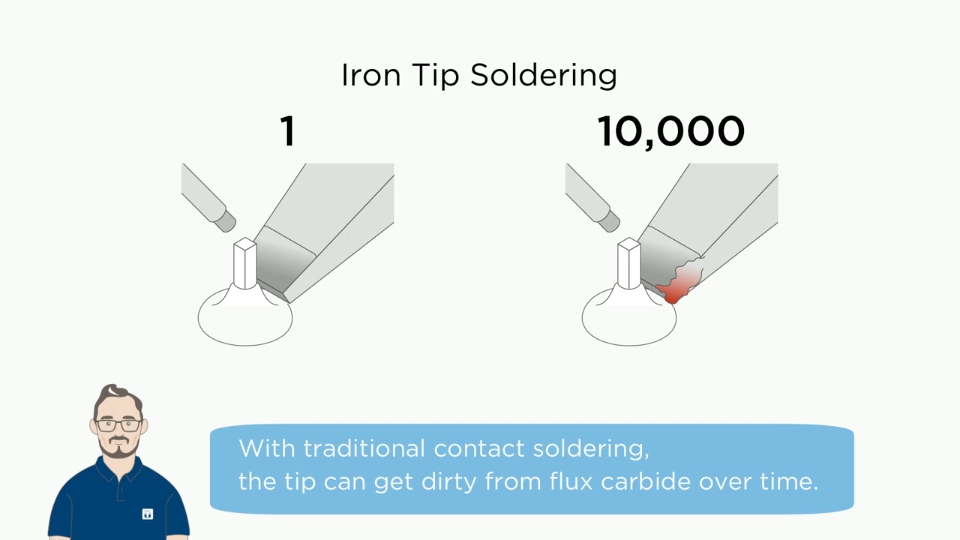

With traditional contact soldering, the tip can get dirty from flux carbide over time.

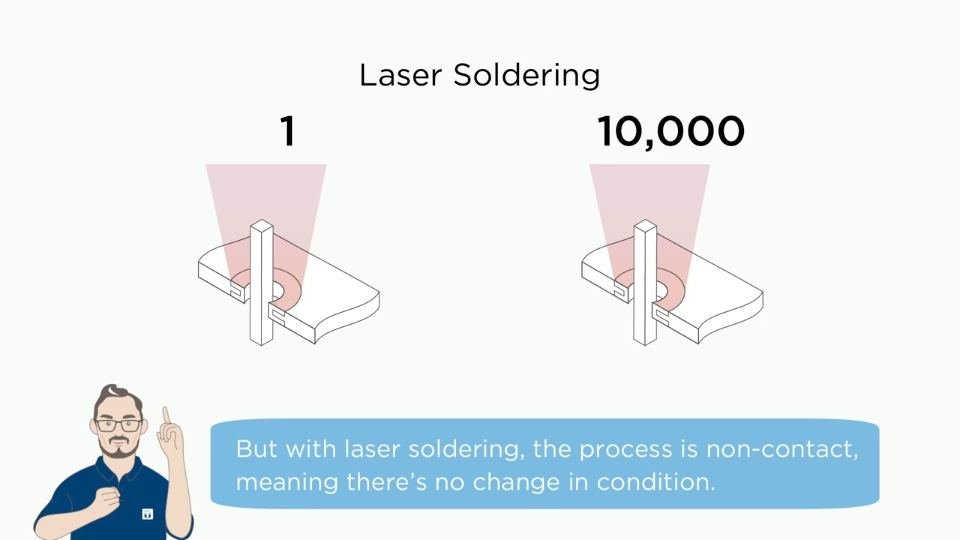

But with laser soldering, the process is non-contact, meaning there’s no change in condition.

As a result, it delivers consistent and stable quality.

Maintainability

Steve The second benefit is its excellent maintainability.

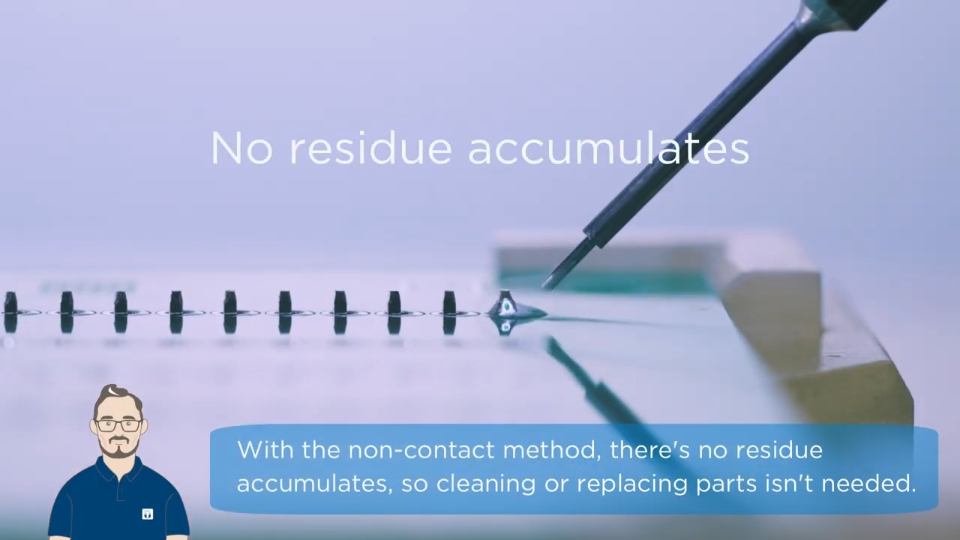

Because it’s non-contact, it doesn’t get dirty, so you don’t need to clean or replace parts.

And since there’s no need to stop the machine for cleaning or parts replacement, it operates efficiently.

Running Cost

Steve The third benefit is its low running cost.

Since there are fewer consumables like replacement parts, expenses are reduced.

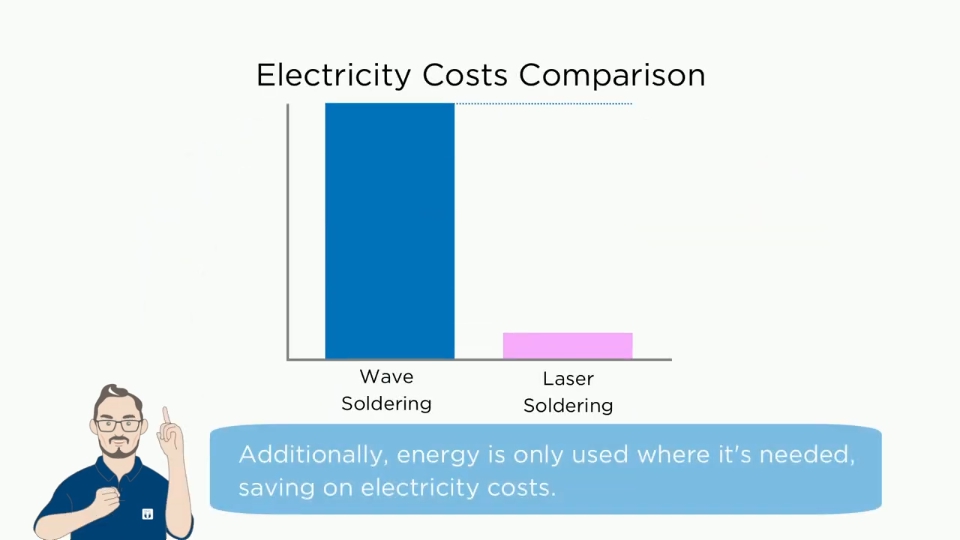

Additionally, energy is only used where it’s needed, saving on electricity costs.

Conclusion

Steve Stable quality, easy maintenance, and low running costs.

Laser soldering robots offer even more benefits beyond these.

If you’d like to know more information, feel free to reach out to Japan Unix anytime.

See you again soon!

Related Products & Services

Video of This Article

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español