"Solder Metal", Soldering News: The Truth of Soldering[YouTube Tech Article]

YOUTUBE Article!

The Truth About Soldering – Soldering News: Solder Metal Edition

Table of Contents

- Theme

- Differences in Metal Composition

- Differences in Flux

- Summary

- Related Products & Services

- Video for This Article

Video for This Article

Theme

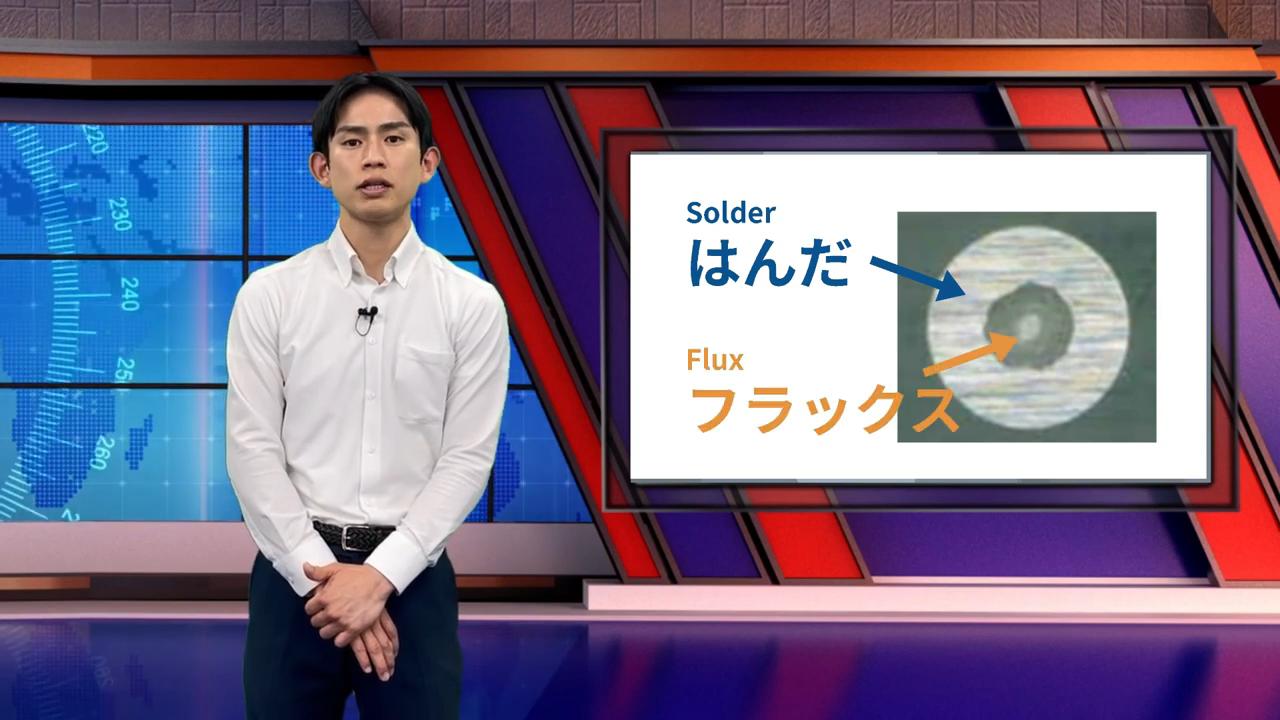

Y Hello everyone. It’s time for the Soldering News, where we reveal the truth about soldering. I, Yanaka, will be your host for today. Today’s theme is about the differences in solder materials.

Are you aware that the solderability changes depending on the materials used? Solder materials consist of two elements: metal composition and flux.

In this session, we will show you how these two elements can change the solderability through a video. Please watch.

About Differences in Metal Composition

Y First, please watch the video about the differences in metal composition.

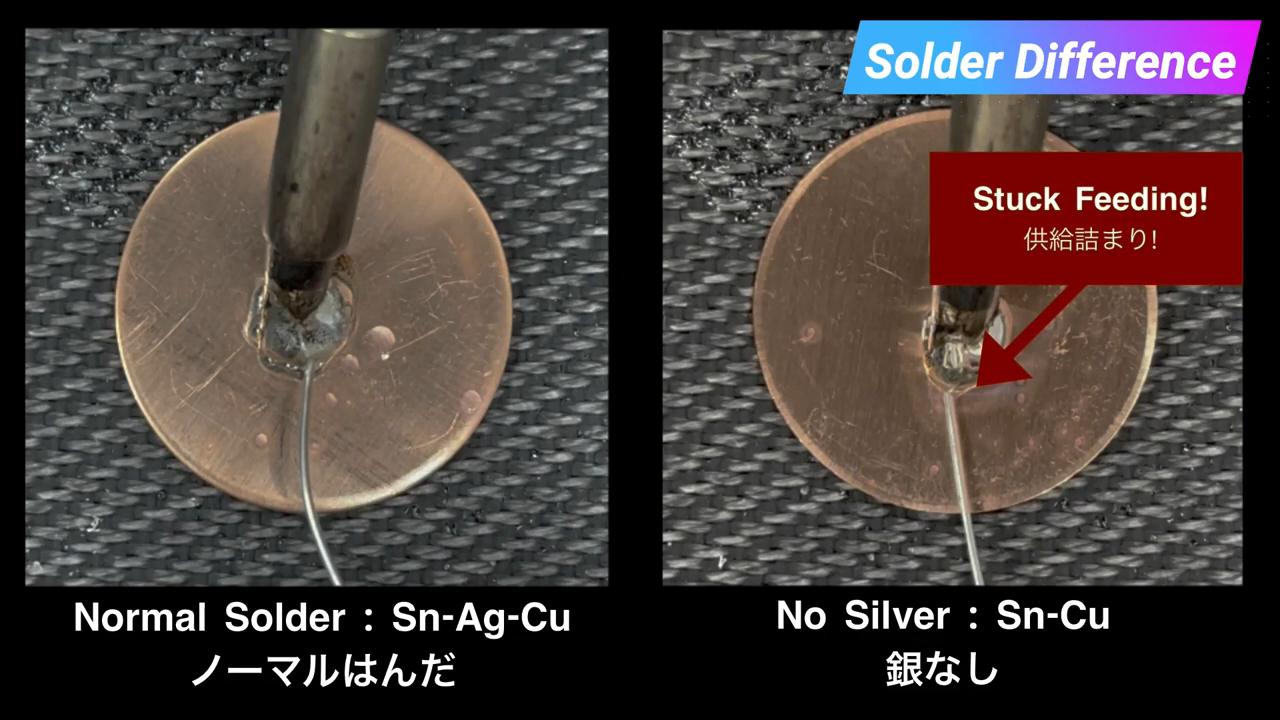

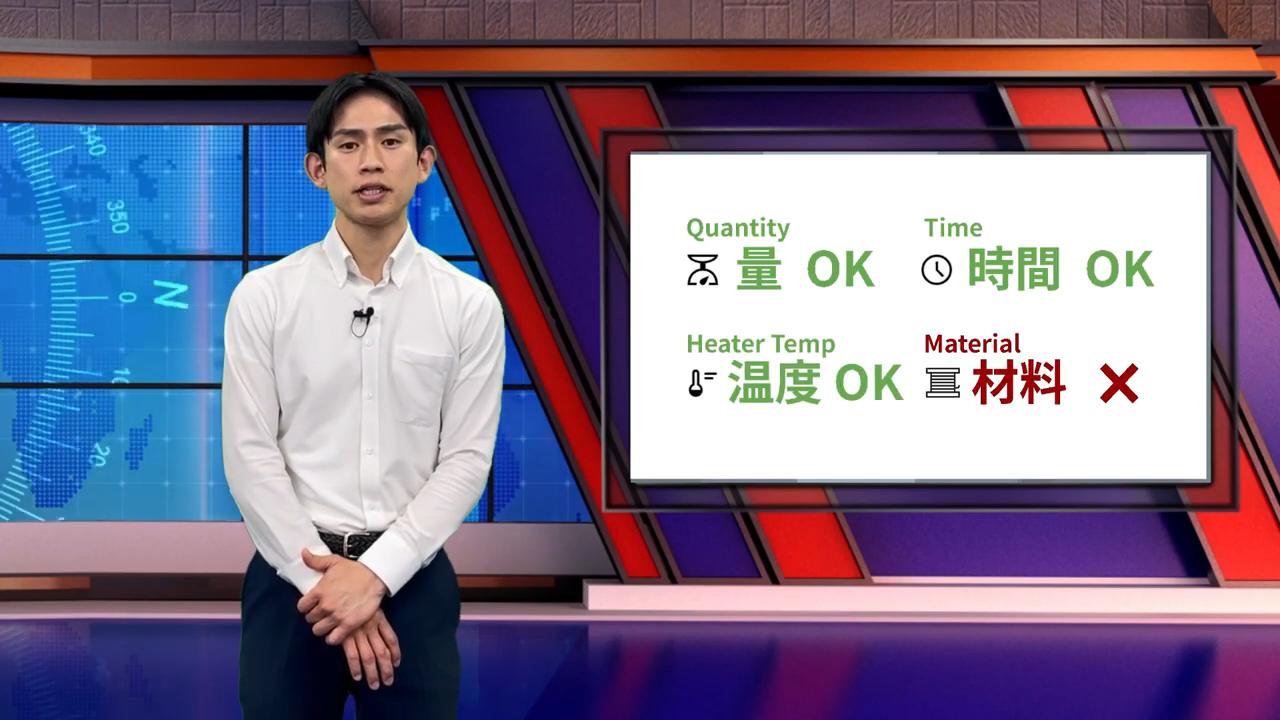

The left shows the common tin, silver, and copper. The right shows silver-free solder. The silver-free solder has clogged, which seems to be due to insufficient heat. Because the solder clogged, it took a bit more time to feed the silver-free solder on the right side.

You can see how solderability changes depending on the metal composition, even if we use the same amount of solder, heat it for the same time, at the same temperature. The main reason for the change in solderability is the difference in melting point. The common solder melts at 217 degrees, whereas the silver-free solder melts at 227 degrees. Even a 10-degree difference in melting temperature can have such an impact on soldering.

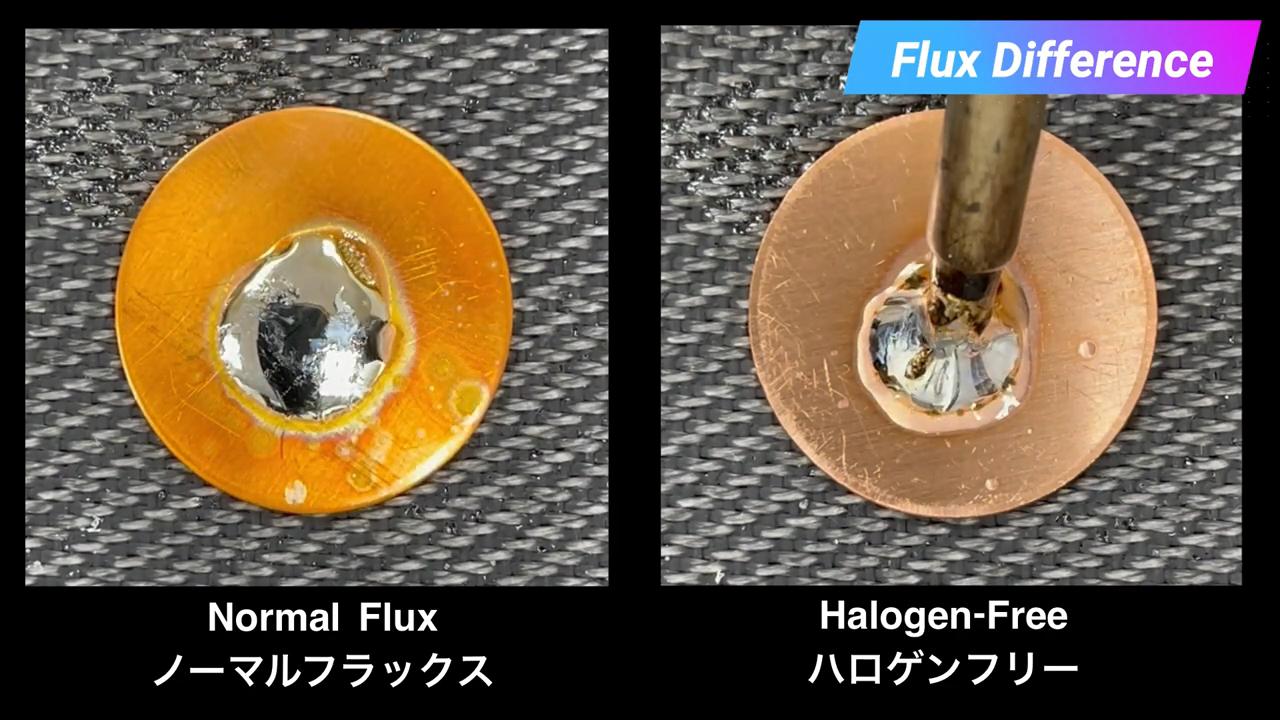

About Differences in Flux

Y Next, let’s talk about the differences in flux. Here, too, let’s watch a video comparing two types of flux. Please.

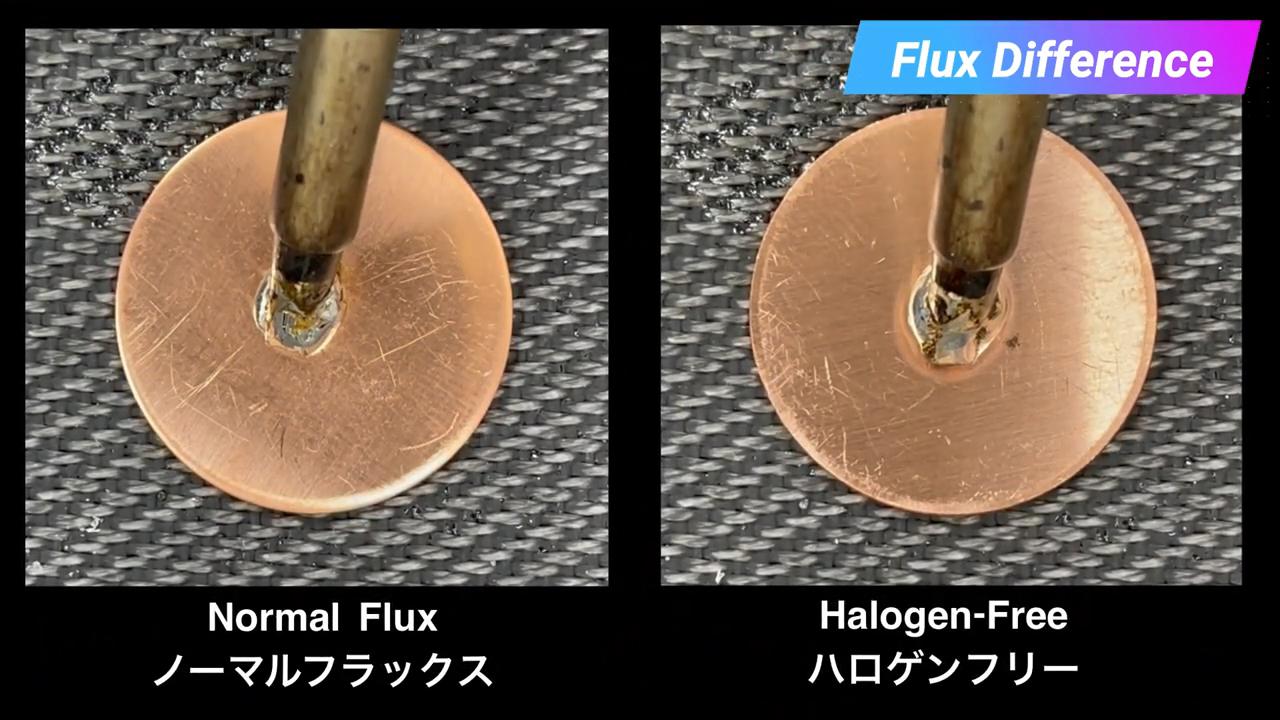

In this video, the same metal composition solder wire is used for both. The left uses standard flux, showing good wettability. The right uses halogen-free solder. The solder on the right side does not spread easily. Finally, the solder has properly wetted the surface.

I think you can see the difference in solderability due to the type of flux. In the case of halogen-free, the cleaning effect and the reduction of surface tension are lower, making it harder for the solder to spread.

Summary

Y As such, solder materials are a significant factor in influencing solderability. Japan Unix conducts comparison tests of solder materials, so feel free to consult with Japan Unix.

See you again. Goodbye.

Related Products & Services

Video for This Article

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español