No-Fail Strategy for Soldering Automation "Preparation" [Steve's Tech Article]

Steve’s Tech Article!

No-Fail Strategy for Soldering Automation “Preparation”

Table of Contents

- Introduction

- Pre-Testing

- Positional Accuracy – Soldering Tip

- Positional Accuracy – Solder Feed

- Positional Accuracy – Product

- Maintenance Planning

- Conclusion

- Related Products & Services

- Video of This Article

Watch the video for this article

Introduction

Steve Hello everyone! I’m Steve, a soldering engineer at Japan Unix.

Today, I’ll talk to you about implementing soldering robots.

What’s the most important thing to consider when introducing a soldering robot?

In our experience with many cases, the answer is “preparation”.

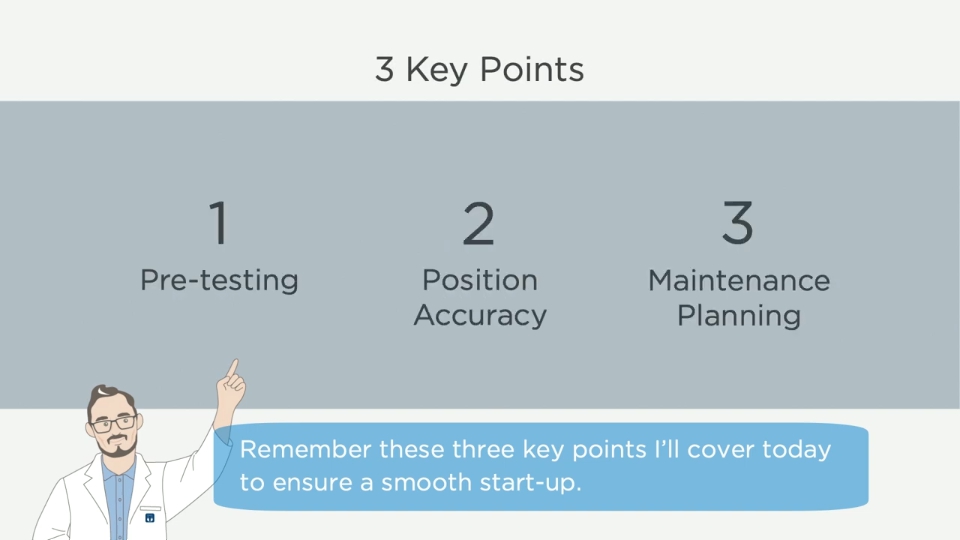

Remember these three key points I’ll cover today to ensure a smooth start-up.

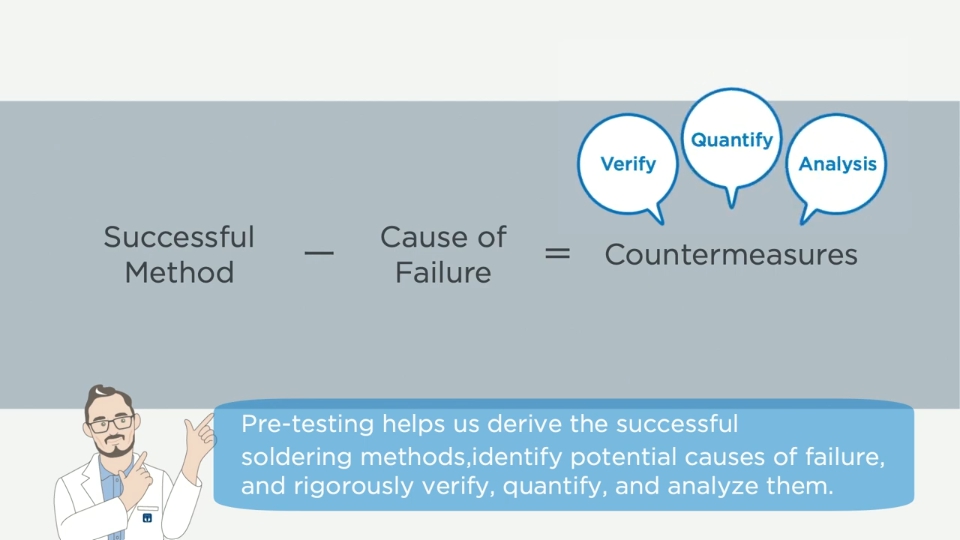

Pre-Testing

Steve The first point is pre-testing.

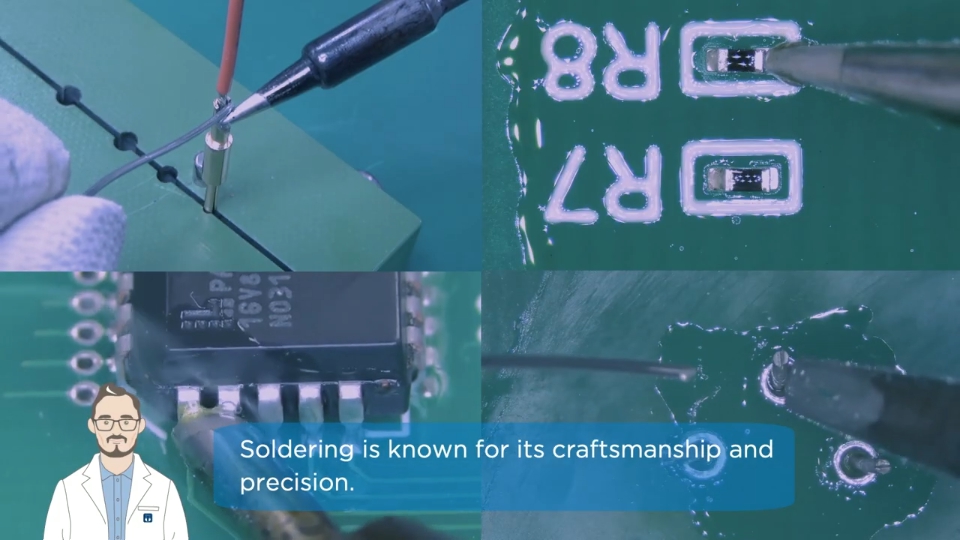

Soldering is known for its craftsmanship and precision.

Your product specifications and factory environment can impact the quality.

Pre-testing helps us derive the successful soldering methods,

identify potential causes of failure,

and rigorously verify, quantify, and analyze them.

By visualizing the process, you must be ready to address issues proactively.

Positional Accuracy

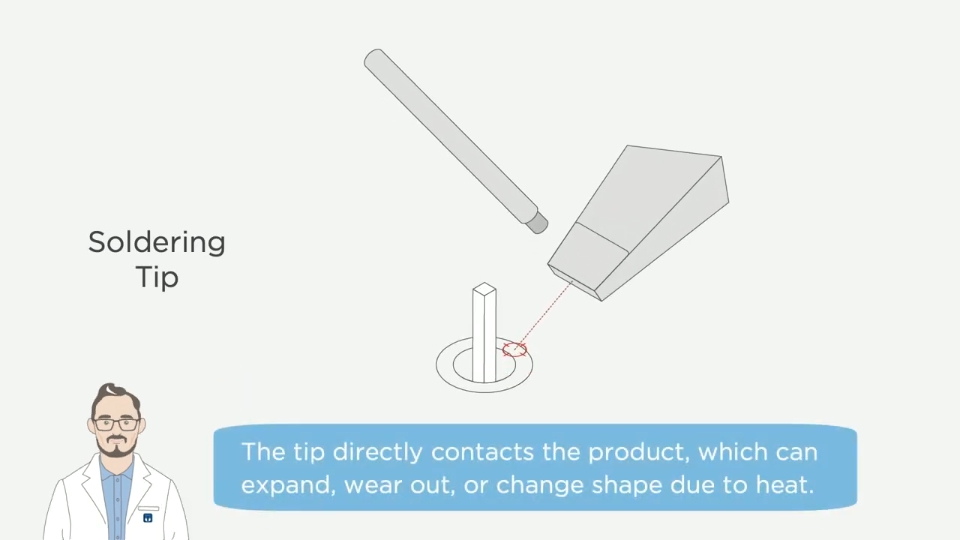

Soldering Tip

Steve First, the soldering tip.

The tip directly contacts the product, which can expand, wear out, or change shape due to heat.

It’s essential to consistently check its position.

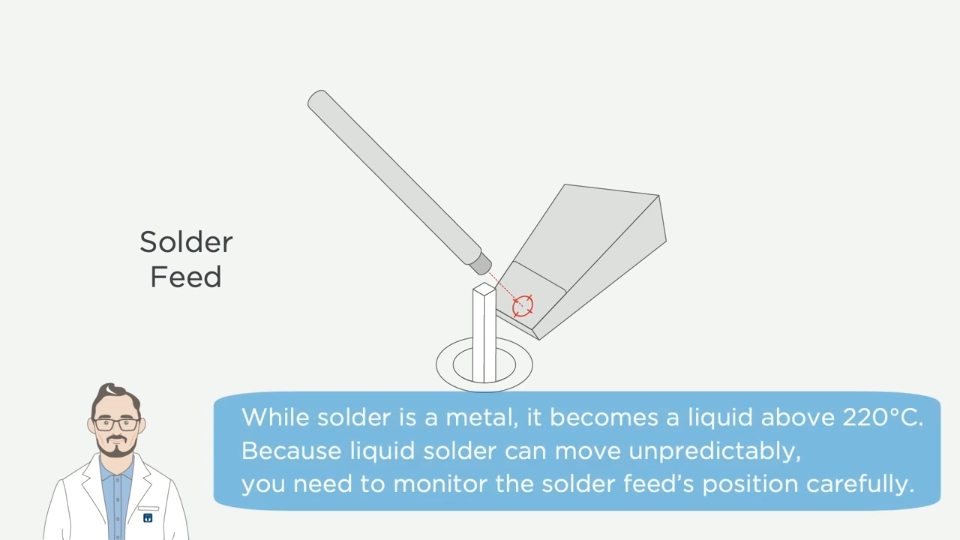

Solder Feed

Steve Next is the solder feed.

While solder is a metal, it becomes a liquid above 220°C.

Because liquid solder can move unpredictably, you need to monitor the solder feed’s position carefully.

Product

Steve Lastly, the product itself.

For example, if there are pins connecting to the product’s components,

their position can affect heat transfer.

Measuring and verifying tolerance limits are crucial.

Maintenance Planning

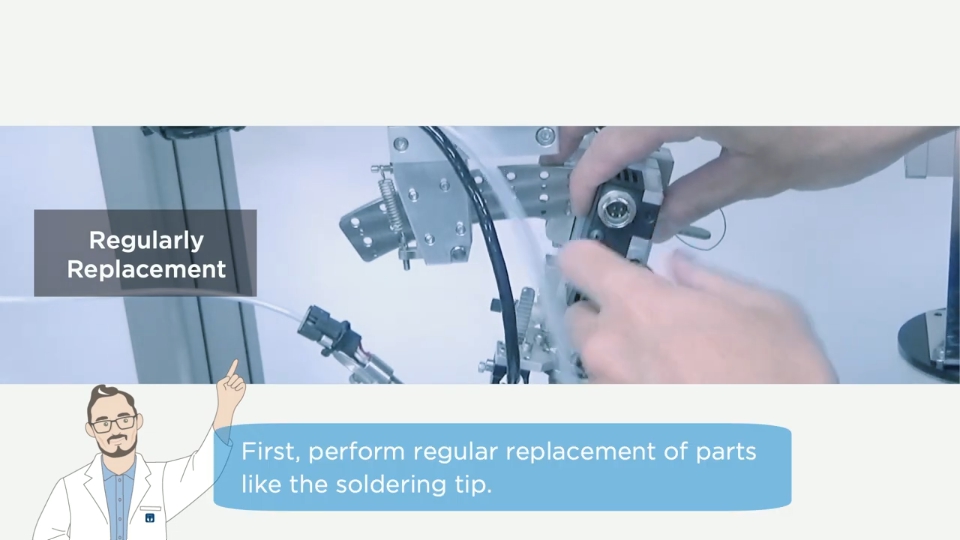

Steve It’s essential to plan for changes due to aging and usage in advance.

First, perform regular replacement of parts like the soldering tip.

This ensures consistent quality.

Next, regularly clean the flux residues on the tip and head.

This helps prevent misalignment and operational issues.

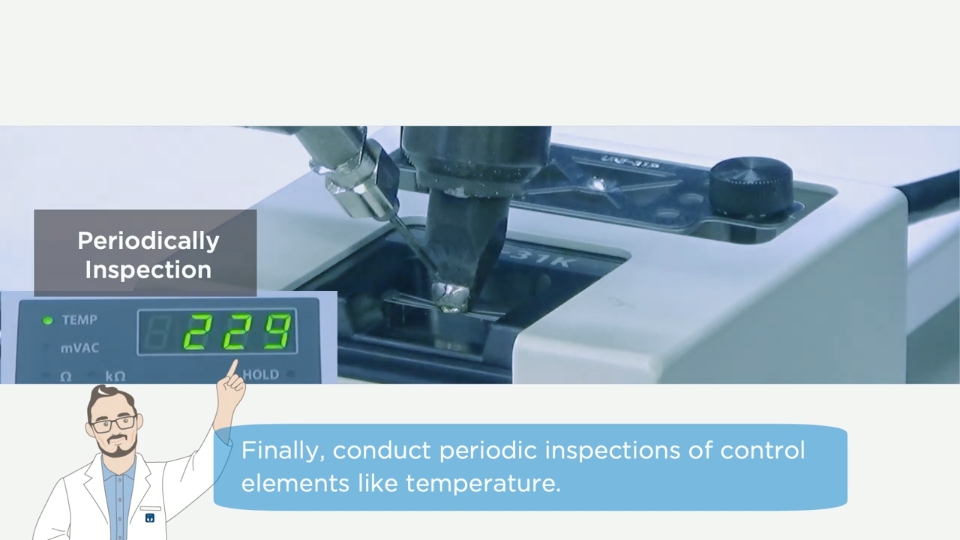

Finally, conduct periodic inspections of control elements like temperature.

This helps prevent the occurrence of variable changes.

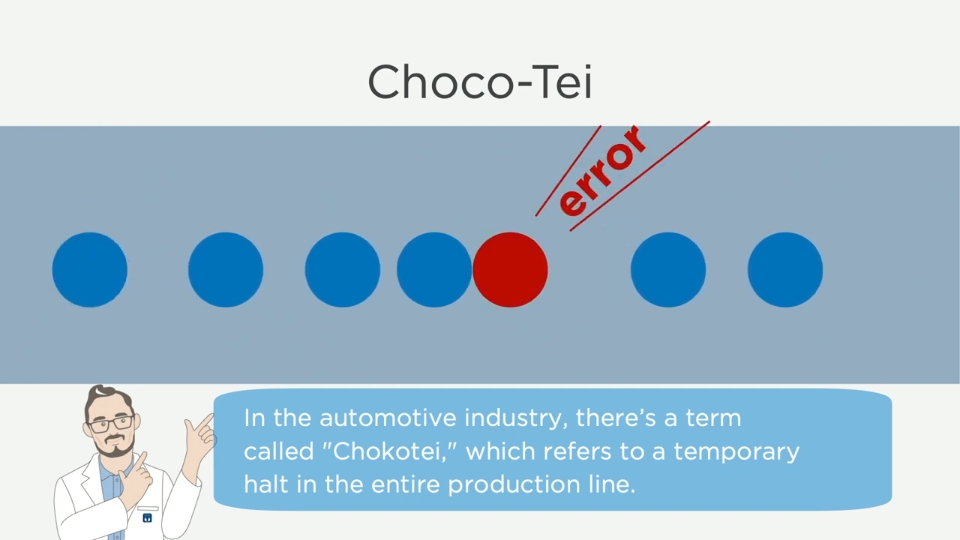

In the automotive industry, there’s a term called “Chokotei,” which refers to a temporary halt in the entire production line.

Frequent stops due to defects or equipment errors can lead to “Chokotei”.

Regular maintenance helps prevent short stoppage, thereby improving both quality and efficiency.

Conclusion

Steve Pre-testing, positional accuracy, and maintenance planning—

focusing on and implementing these three aspects during installation is the key to a smooth startup.

For those of you considering soldering automation, if you have questions or need advice, feel free to reach out to Japan Unix anytime.

We’re always ready to support you.

See you again soon!

Related Products & Services

Video of This Article

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español