Let's Try Soldering! High Heat Capacity - Power Supply Terminal by Tip Soldering and Laser

22nd YOUTUBE Article!

Let’s Try Soldering Series: Power Terminals

Table of Contents

- Introduction

- Tip Soldering

- Laser Soldering

- Conclusion

- Related Products & Services

- Video of This Article

Here is the video for this article

What is automatic soldering of power terminals used for?

Naka Hello everyone. This is Nakano from Japan Unix.

Yana I am Yanaka from the Technical Department. Nice to meet you.

Naka Today, we are discussing power terminals,. Globally, there is an increase in products that handle large currents, such as large motors and chargers.

Yana Soldering of power terminals is increasing for large products such as electric vehicles, robots, and smart meters.

Naka The heat capacity is also large, so it seems that the difficulty of soldering will increase.

Automatic Tip Soldering of Power Terminals

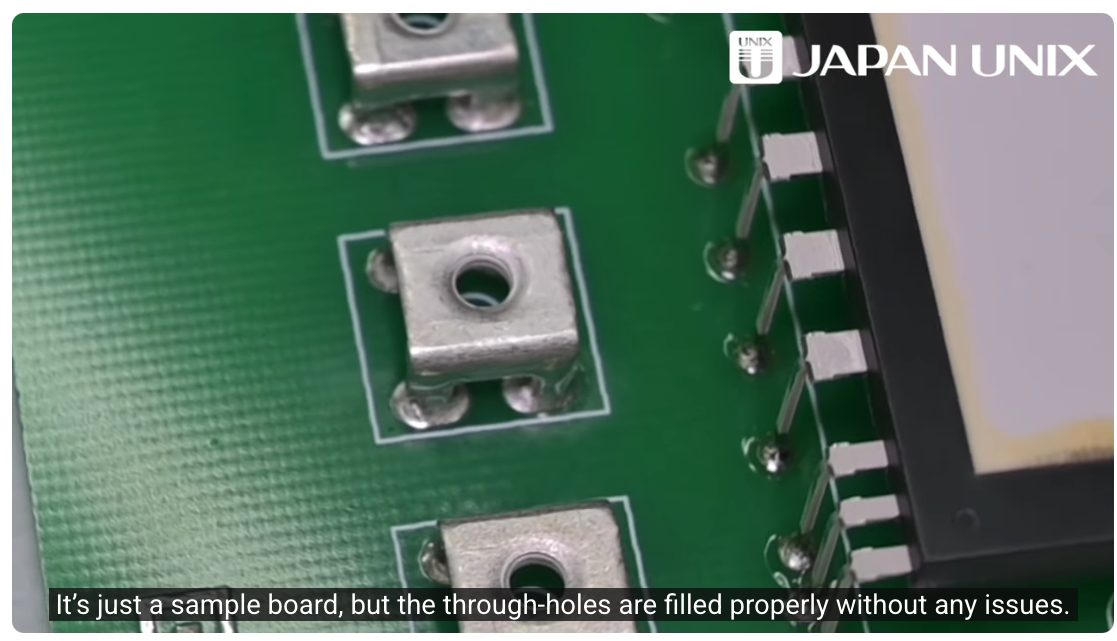

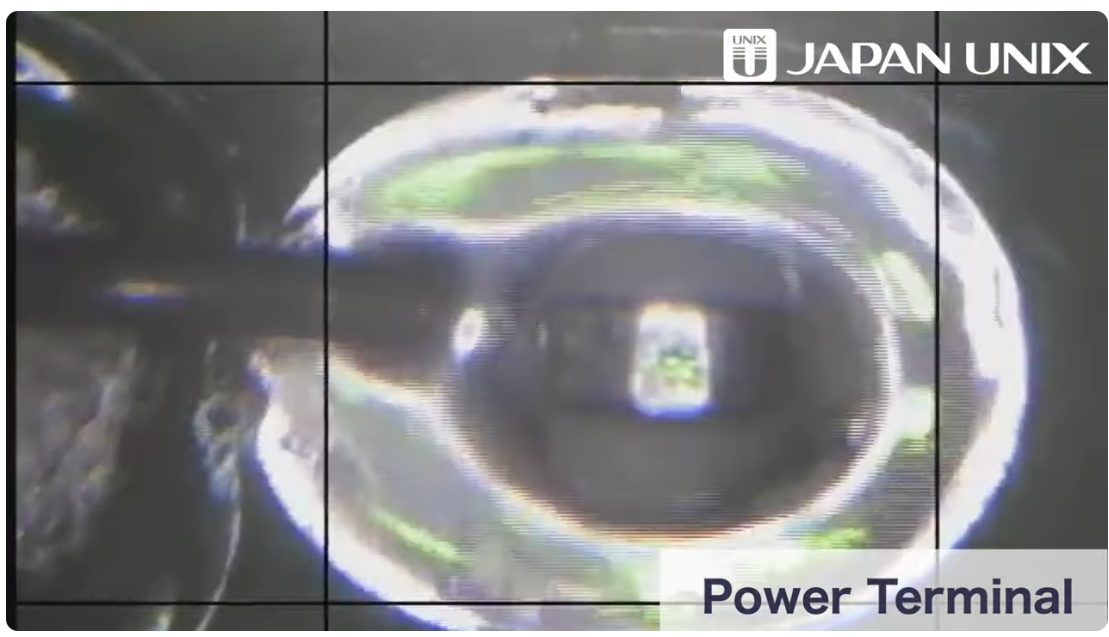

Naka First, we have a video of tip soldering, so please take a look. Here it is. This is a product soldered with a soldering tip. Although it’s a sample board, the through-holes are properly filled without any issues. Please tell us about the precautions for soldering power terminals.

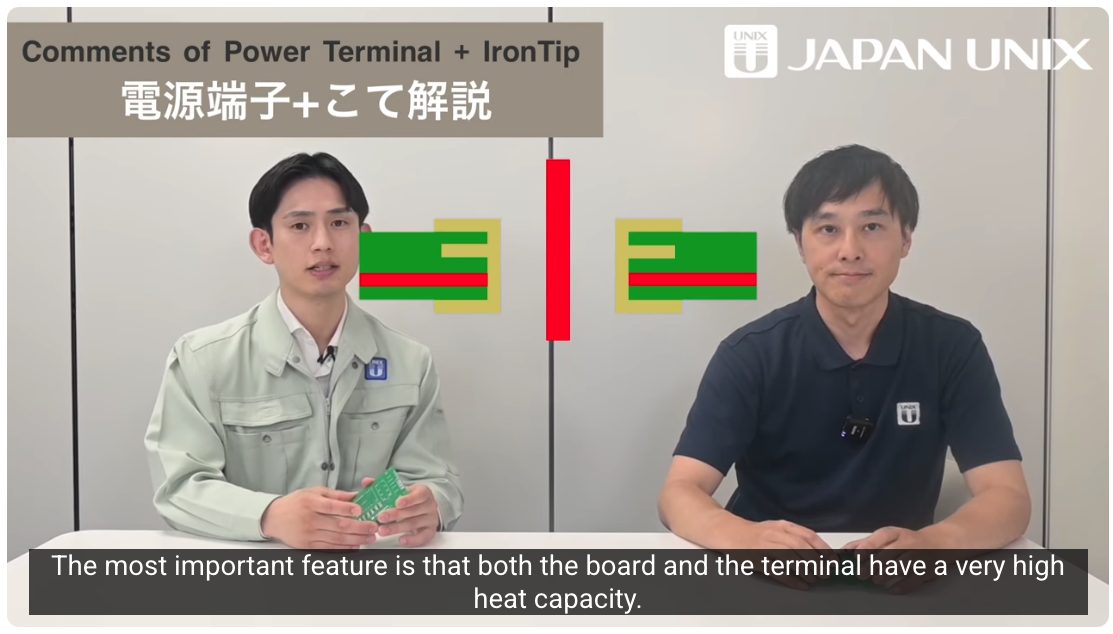

Yana The main feature is that both the board side and the terminal side have a very large heat capacity. Therefore, it is necessary to increase the heater temperature or extend the contact time.. Also, a point to note is that if the soldering tip temperature is raised too much or the contact time is extended too long, the flux may become inactive, leading to insufficient filling of through-holes or poor wetting on the surface.

Naka So it means that pre-verification of soldering conditions and selection of optimal soldering materials are necessary.

Yana That’s right.

Laser Soldering of Power Terminals

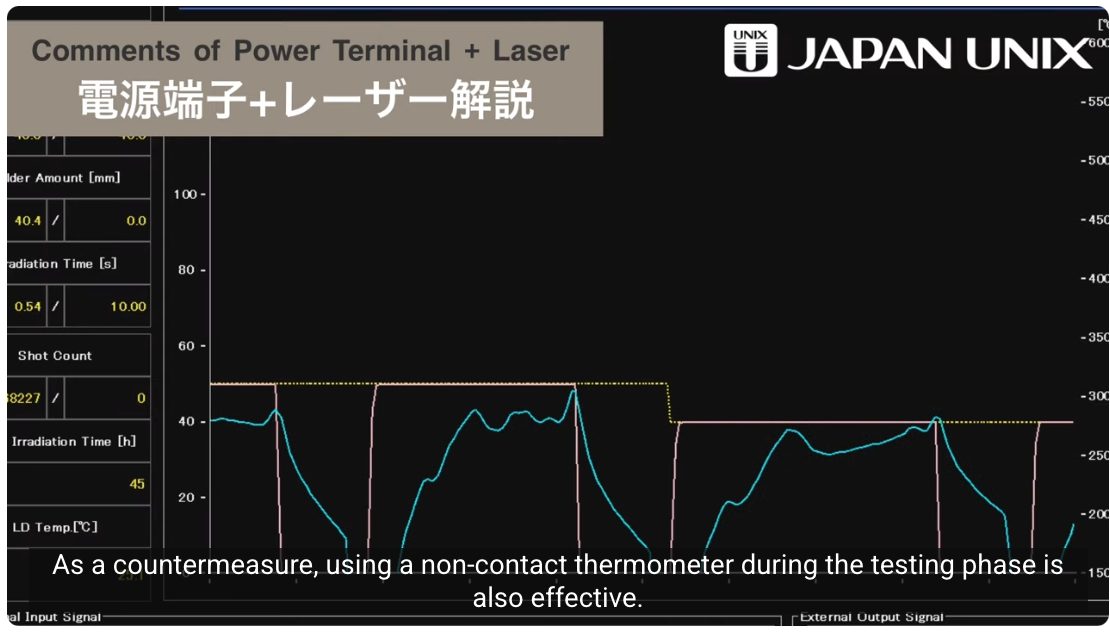

Naka Next, let’s take a look at laser soldering. Here it is. This is the product soldered with a laser. It is also soldered cleanly without any issues. Please tell us about the features and precautions of laser soldering.

Yana Yes. In the case of oval or rectangular pads, heat tends to not spread well throughout. However, if you increase the laser output too much or extend the irradiation time too long, there is a possibility of damaging the components, so you need to be careful.

Naka For lasers, strict temperature control is necessary to prevent burning the components.

Yana Therefore, as a countermeasure, temperature management using a non-contact thermometer during the experimental phase is effective.

Conclusion

Yana Adjusting soldering conditions is a very important factor in soldering. We will firmly support you in this regard, so please feel assured.

Naka Thank you very much, Mr. Yanaka, for today.

Yana Thank you very much.

Naka For soldering automation experiments, please feel free to contact Japan Unix. See you in the next video. Goodbye.

Related Products & Services

Video of This Article

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español