IPC Soldering Contest 2022 Scoring Results!

Contest Scoring Results Report Feature!

What is IPC Hand Soldering Contest?

IPC Hand Soldering Contest is the Japanese tournament of the Hand Soldering Competition organized by the international standardization body IPC. It aims to highlight the skills of hand soldering technicians who have special techniques for soldering components on printed circuit board assemblies.

IPC organizes hand soldering competitions (Hand Soldering Competition) at various venues such as exhibitions worldwide, supporting soldering technicians from around the world and showcasing their skills on a global stage. In this competition, highly skilled hand soldering technicians representing companies participate and perform soldering on printed circuit boards within the specified time, competing for quality assessment based on IPC-A-610 and J-STD-001 standards, as well as demonstrating rework and repair procedures and high-quality workmanship based on IPC-7711/21.

IPC holds competitions for professionals and students in the field, awarding cash prizes to the winners, runners-up, and third-place participants. The Japanese tournament used the UNIXJBC soldering station, a high-performance soldering iron, for the competition.

IPC Hand Soldering Champions

IPC organizes hand soldering competitions (Hand Soldering Competition) in various countries and regions at venues such as exhibitions worldwide, supporting soldering technicians from around the world and showcasing their skills on a global stage. In this competition, highly skilled hand soldering technicians representing companies participate and perform soldering on printed circuit boards within the specified time, competing for quality assessment based on IPC-A-610 and J-STD-001 standards, as well as demonstrating rework and repair procedures based on IPC-7711/21.

IPC holds competitions for professionals and students in the field, awarding cash prizes to the winners, runners-up, and third-place participants. The Japanese tournament used the UNIXJBC soldering station, a high-performance soldering iron.

10/26-28 IPC Hand Soldering Contest 2022 in Nagoya

productronica

Scoring Results Announcement!

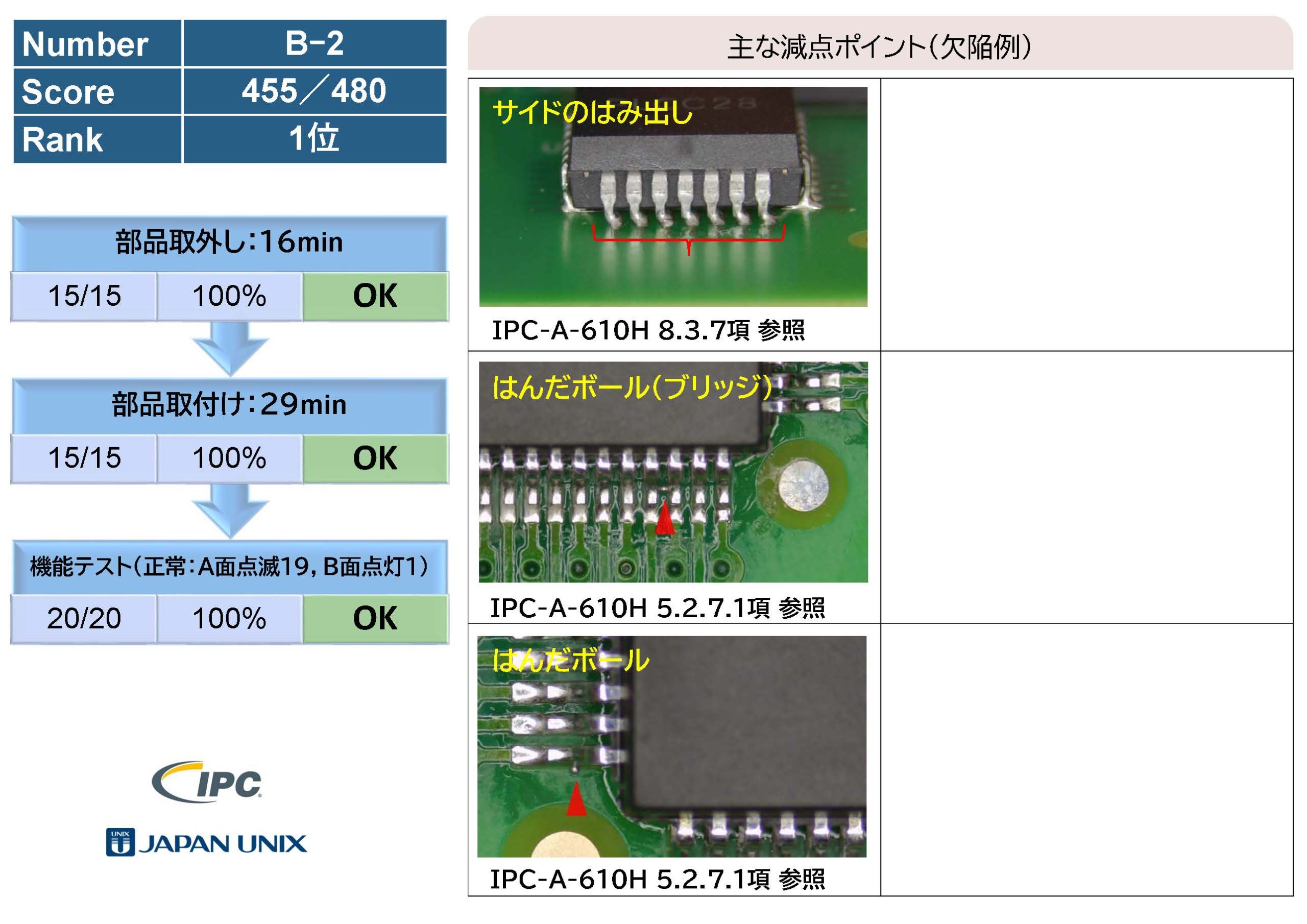

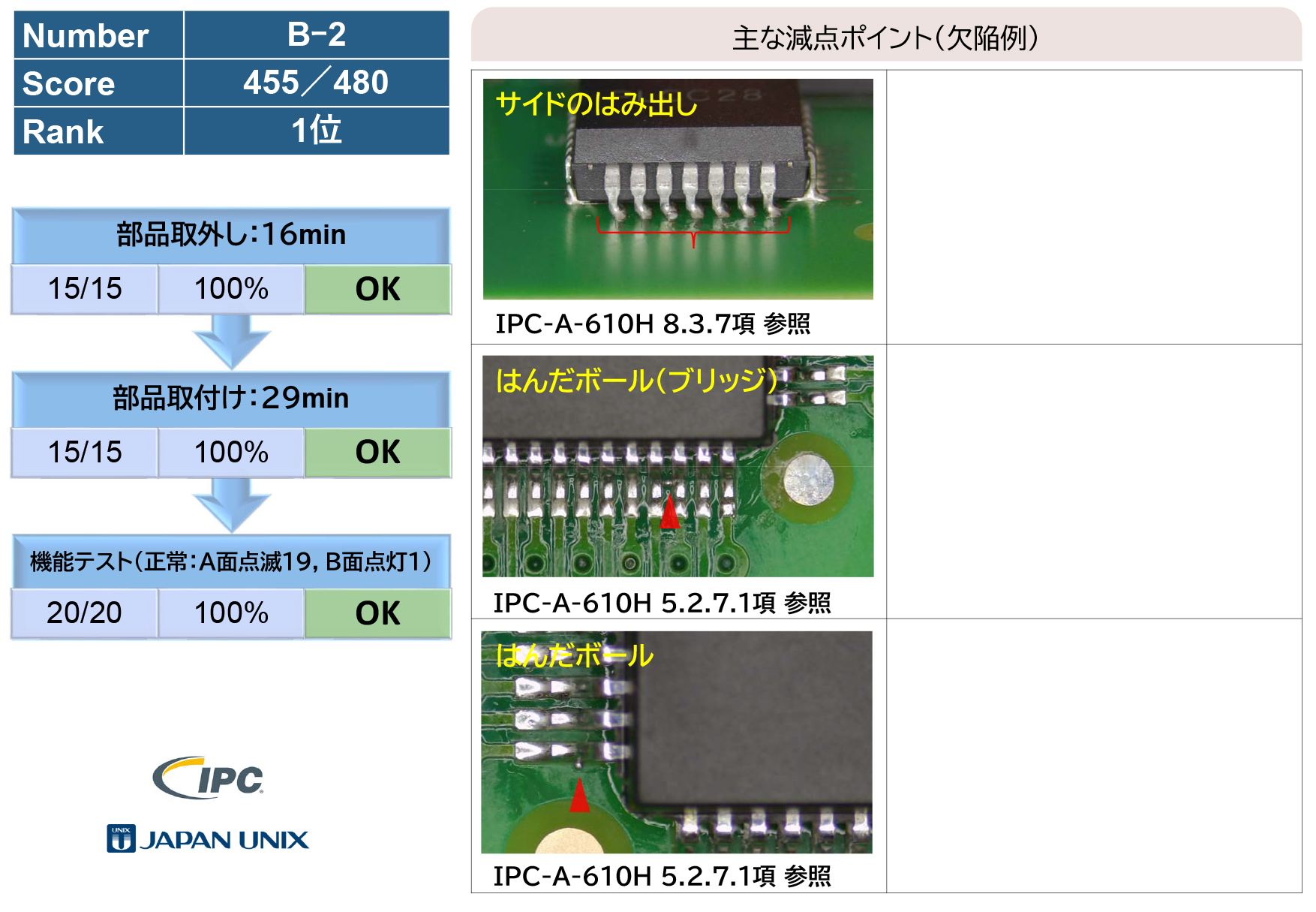

1st Place Result Explanation and Main Deduction Points

2nd Place Result Explanation and Main Deduction Points

The 2nd place winner also successfully completed component desoldering, component soldering, and functional testing. Unfortunately, they became the 2nd place due to a difference in scores.

The main deduction points that were identified (refer to the figure on the right) include insufficient solder fill in through-hole components, i.e., insufficient wetting between the leads and the hole walls, “side protrusion,” non-compliant insulation clearance of coated lead wires, and no contact between components and spacers.

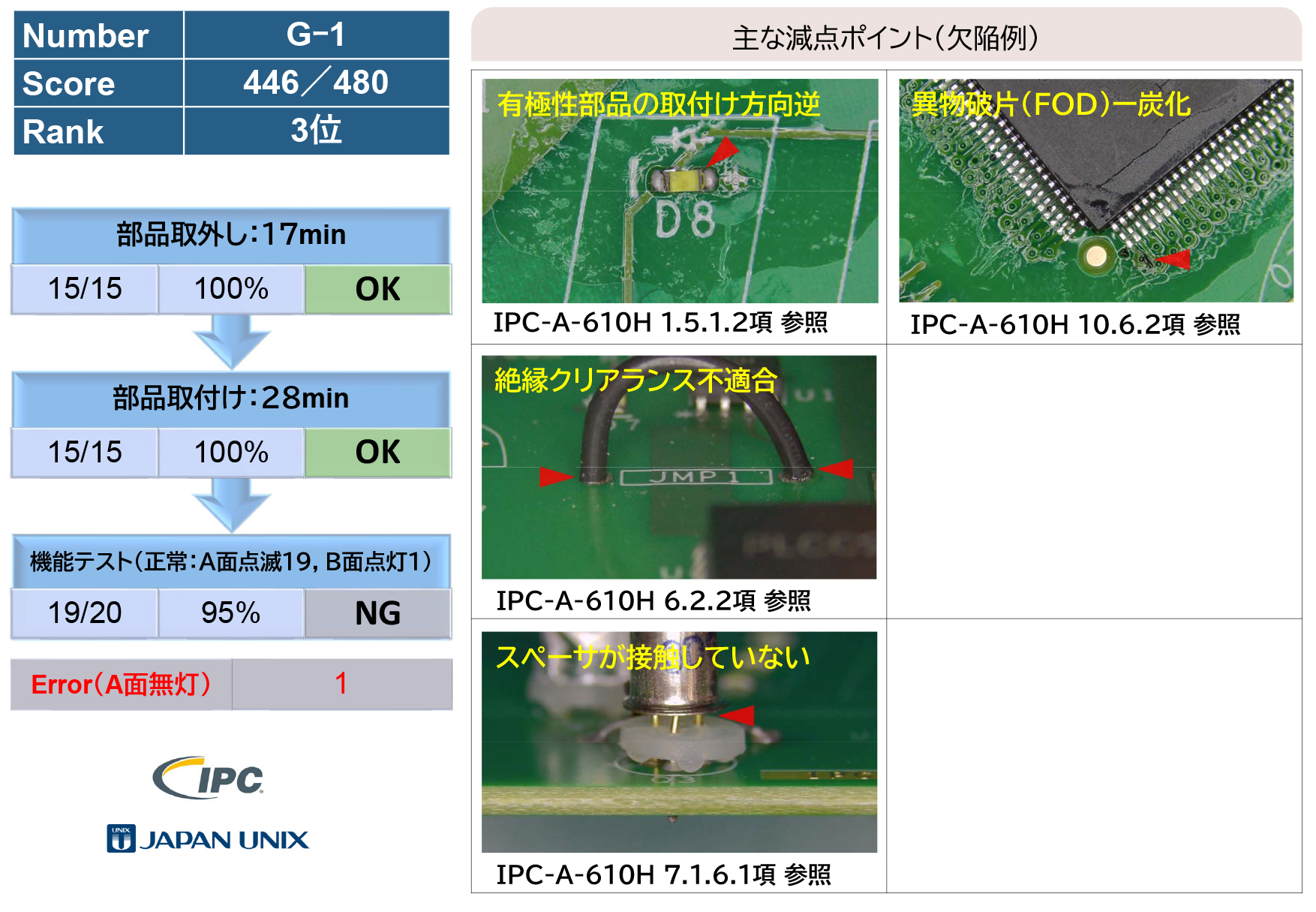

3rd Place Result Explanation and Main Deduction Points

The quality score was the second highest in this contest, but the 3rd place winner missed out due to one LED not lighting up during functional testing, as the evaluation of the three processes takes priority.

The main deduction points that were identified (refer to the figure on the right) include reverse mounting direction of polarized components, which was the reason for the LED not lighting up. Other deduction points include FOD, adhesion of carbonized foreign particles, non-compliant insulation clearance of coated lead wires, and no contact between components and spacers.

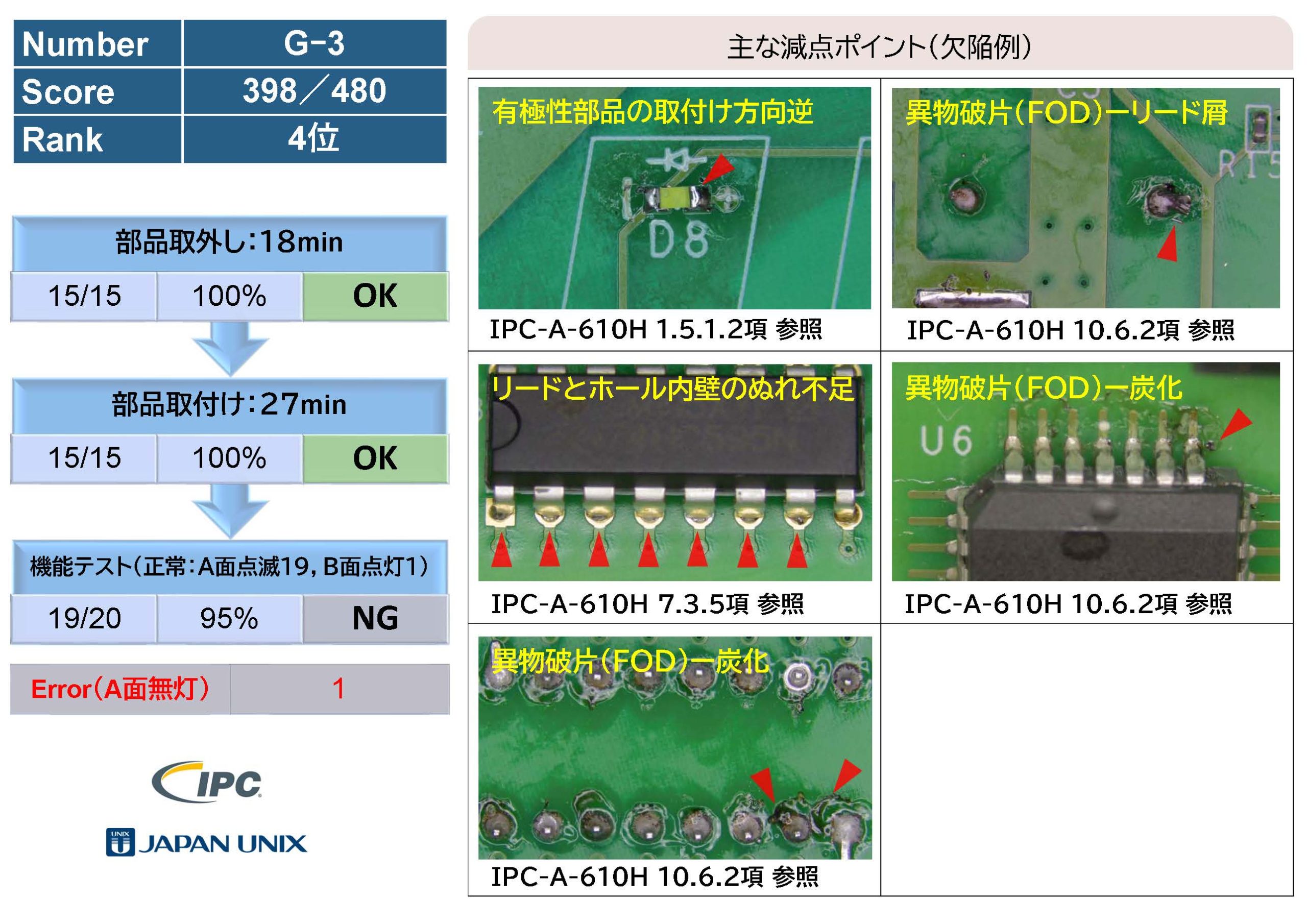

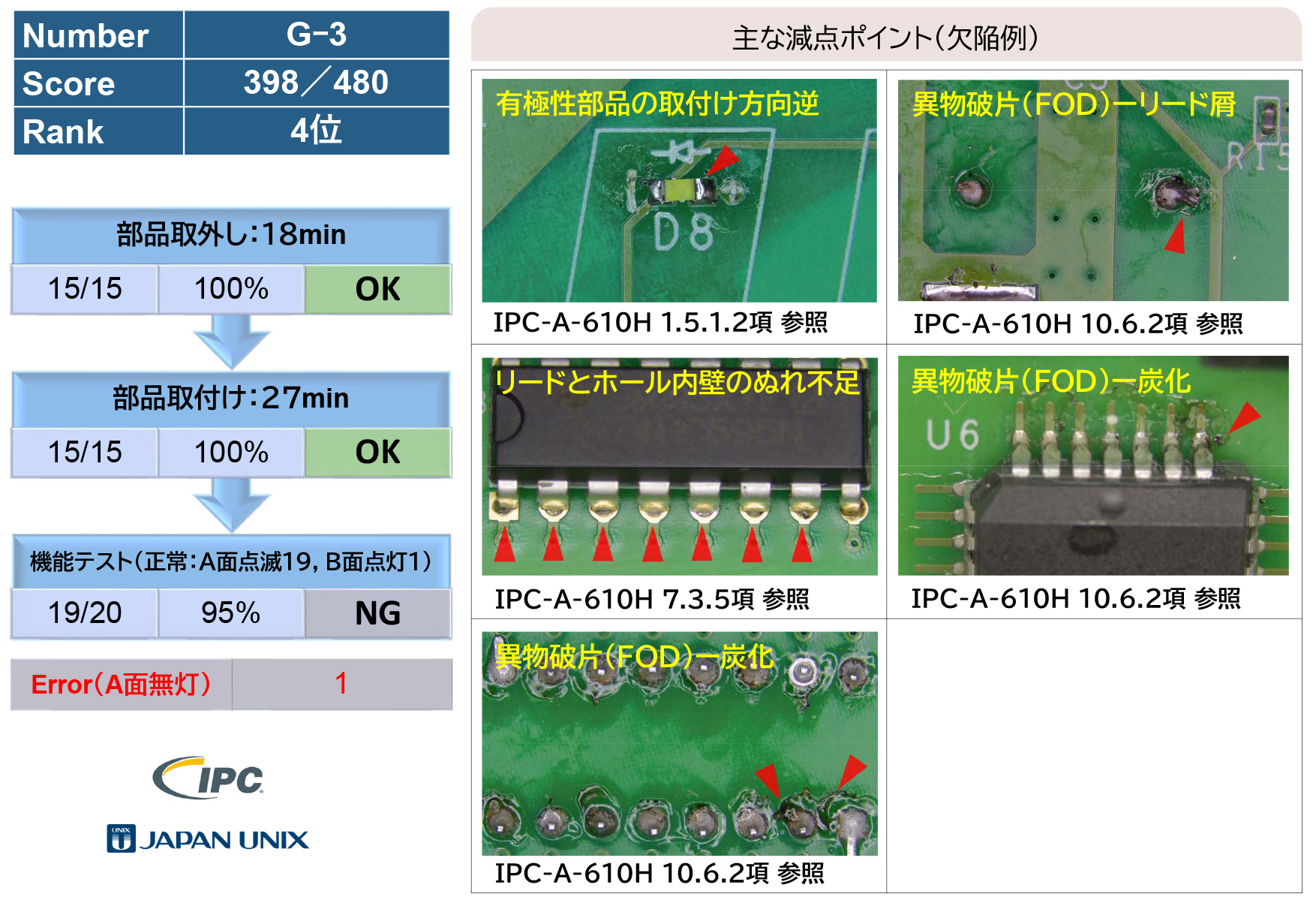

4th Place Result Explanation and Main Deduction Points

Main Deduction Points for 5th-7th Place Winners

Please refer to the overall results for the rankings and scores of the 5th-7th place winners.

Here, we will list the main deduction points:

– Insufficient wetting of QFPs

– Adhesion of carbonized foreign particles

– Components not soldered

– Insufficient overlap between chip components and one side of the pads

– “Side protrusion” of J-leads

– Insufficient wetting at the end of terminals

– No contact between components and spacers

– Solder bridging

– Reverse mounting direction of polarized components

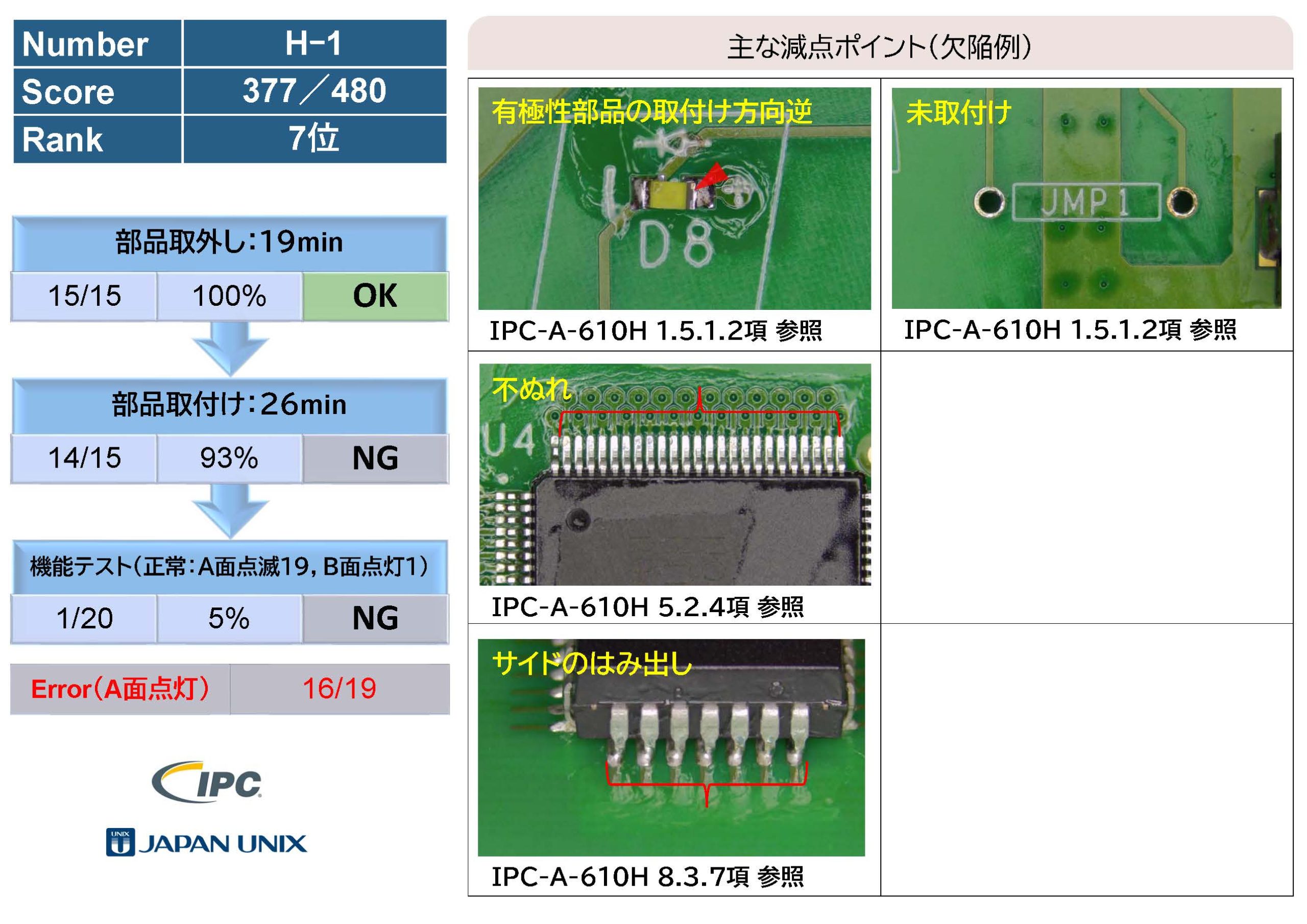

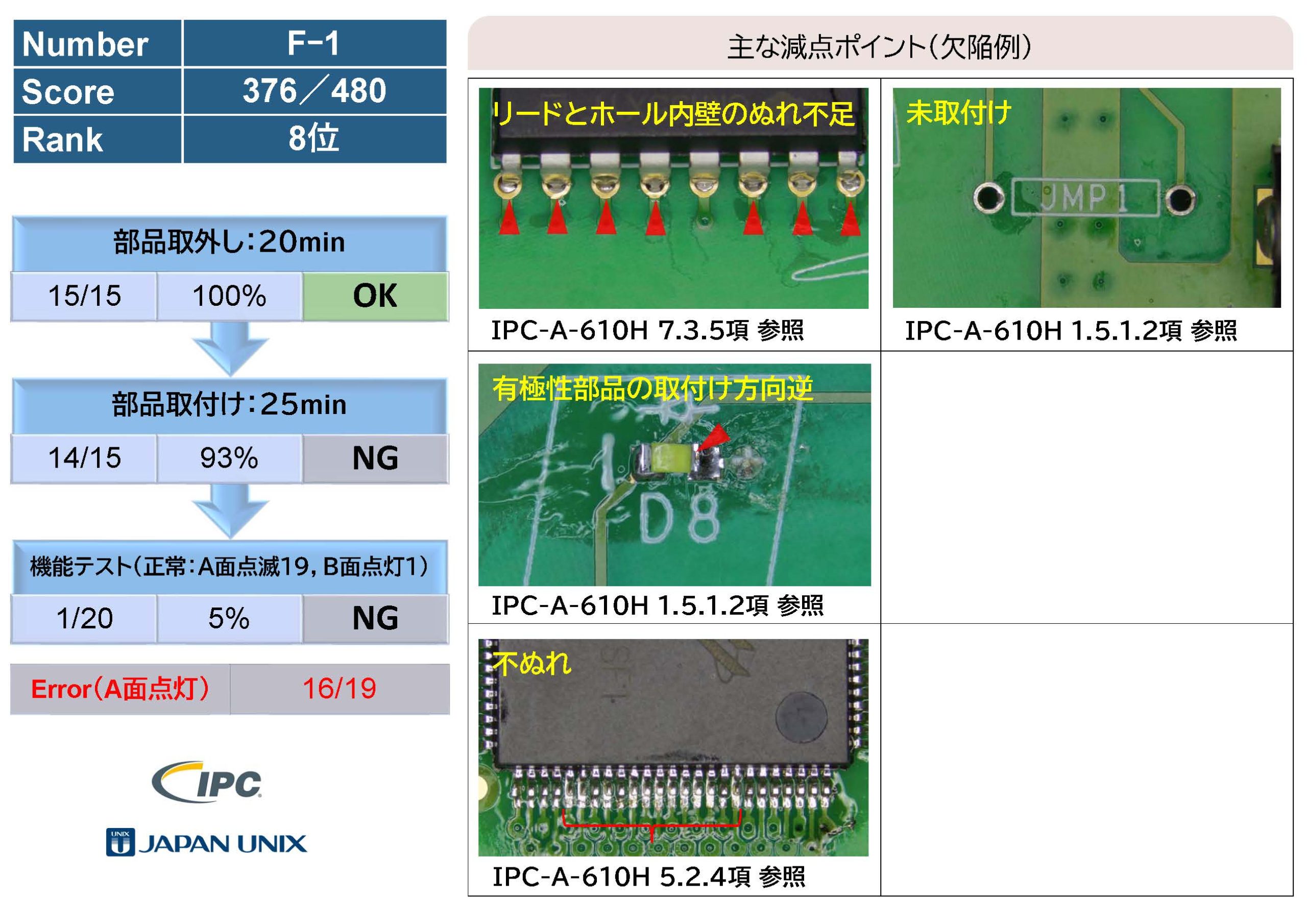

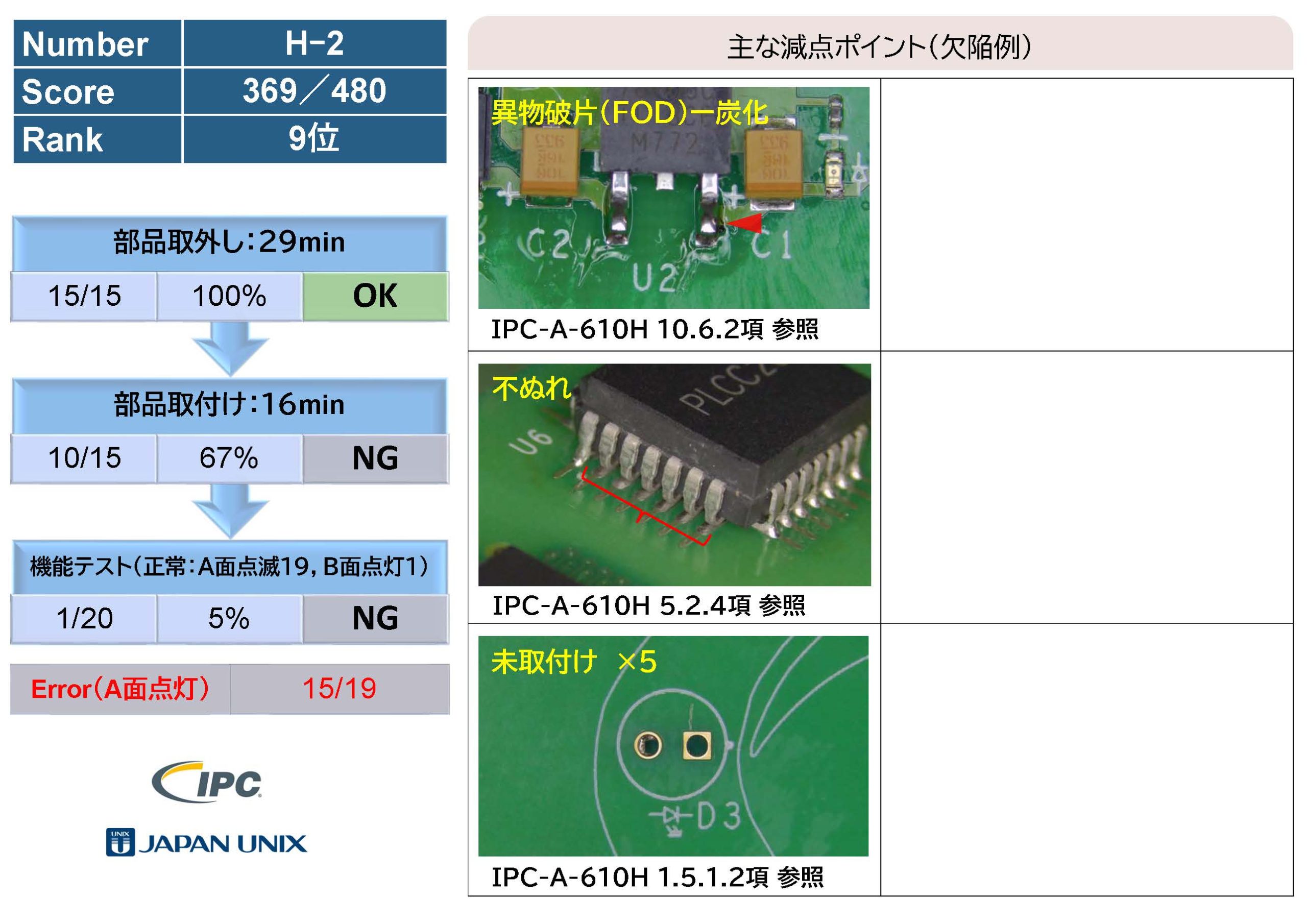

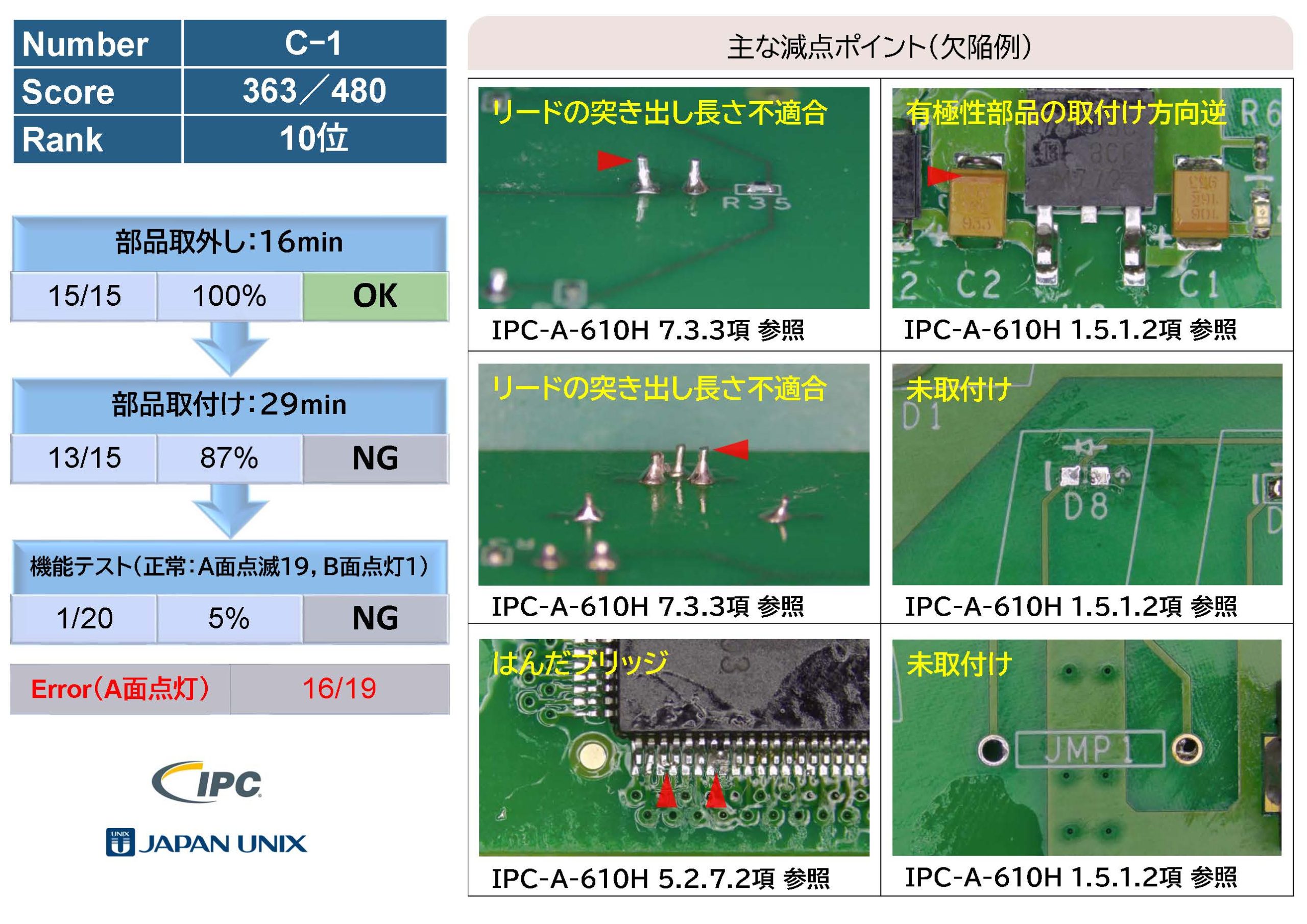

Main Deduction Points for 8th-10th Place Winners

Please refer to the overall results for the rankings and scores of the 8th-10th place winners.

Here, we will list the main deduction points:

– Components not soldered

– Abnormal protrusion length of leads

– Reverse mounting direction of polarized components

– Insufficient wetting of J-leads

– Adhesion of carbonized foreign particles

– Insufficient wetting between lead-insertion components and hole walls

– Solder bridging

Overall Results

| Rank | Score | Number |

|---|---|---|

| 1st | 455/480 | B-2 |

| 2nd | 434/480 | F-2 |

| 3rd | 446/480 | G-1 |

| 4th | 398/480 | G-3 |

| 5th | 424/480 | D-2 |

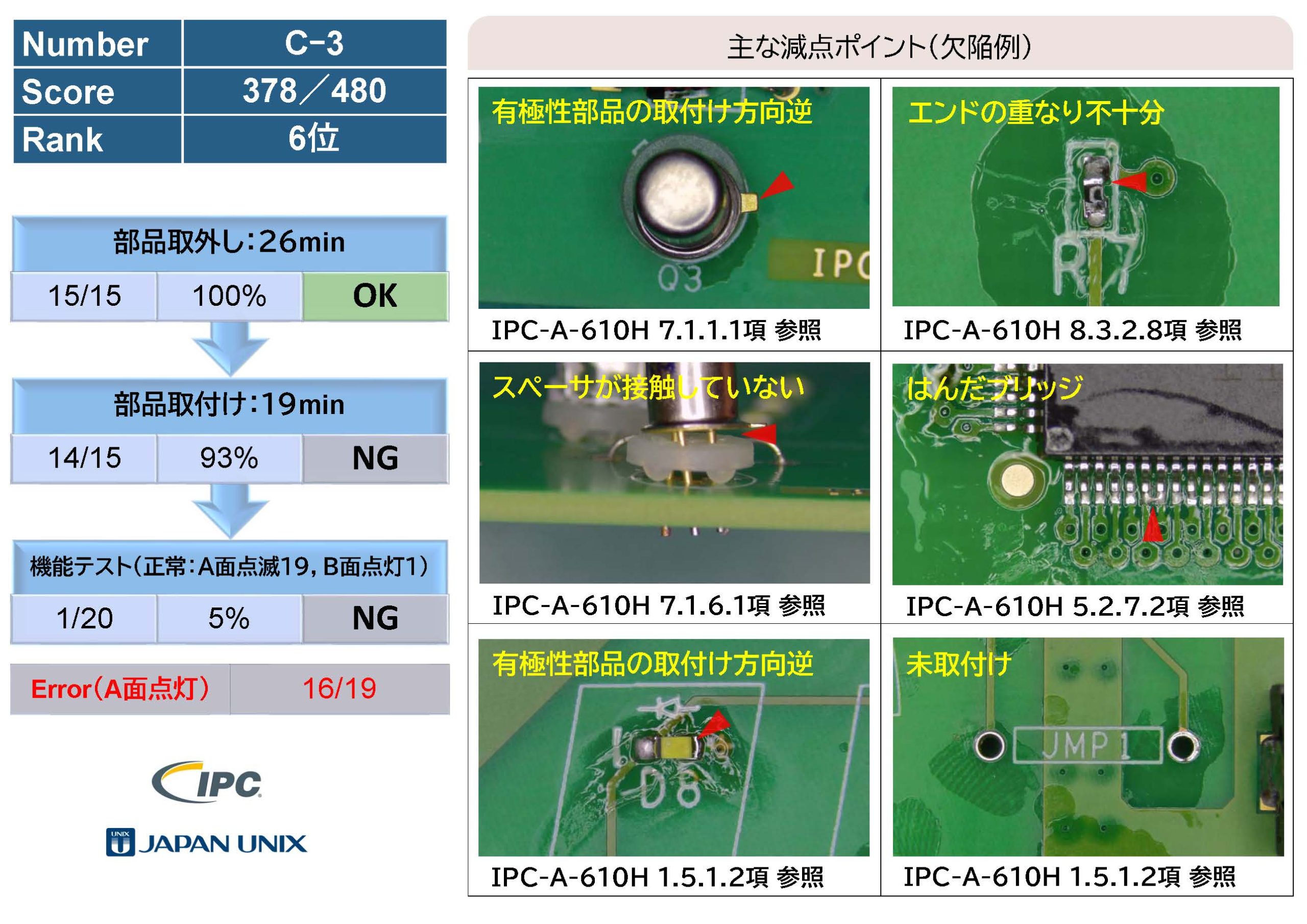

| 6th | 378/480 | C-3 |

| 7th | 377/480 | H-1 |

| 8th | 376/480 | F-1 |

| 9th | 369/480 | H-2 |

| 10th | 363/480 | C-1 |

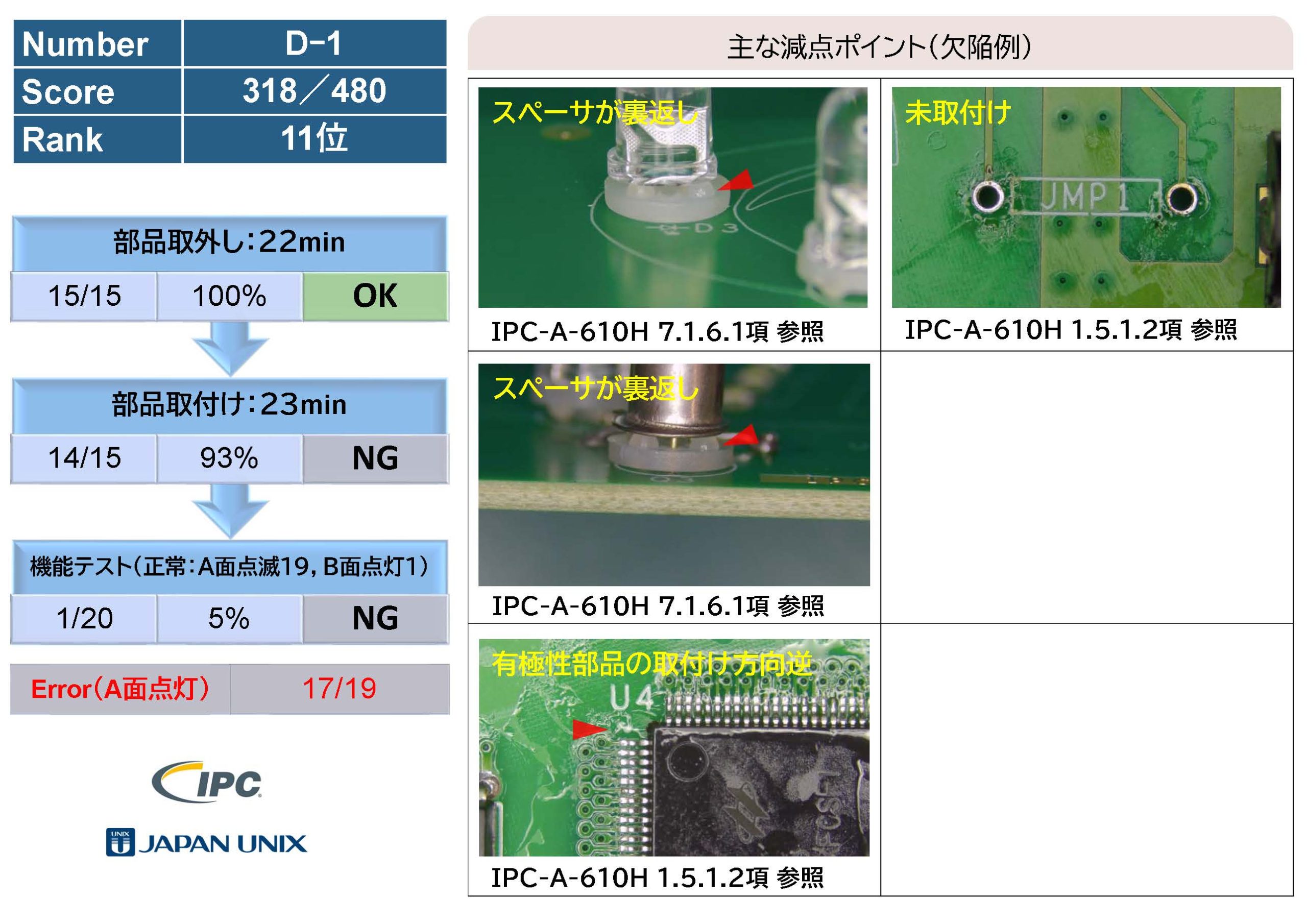

| 11th | 318/480 | D-1 |

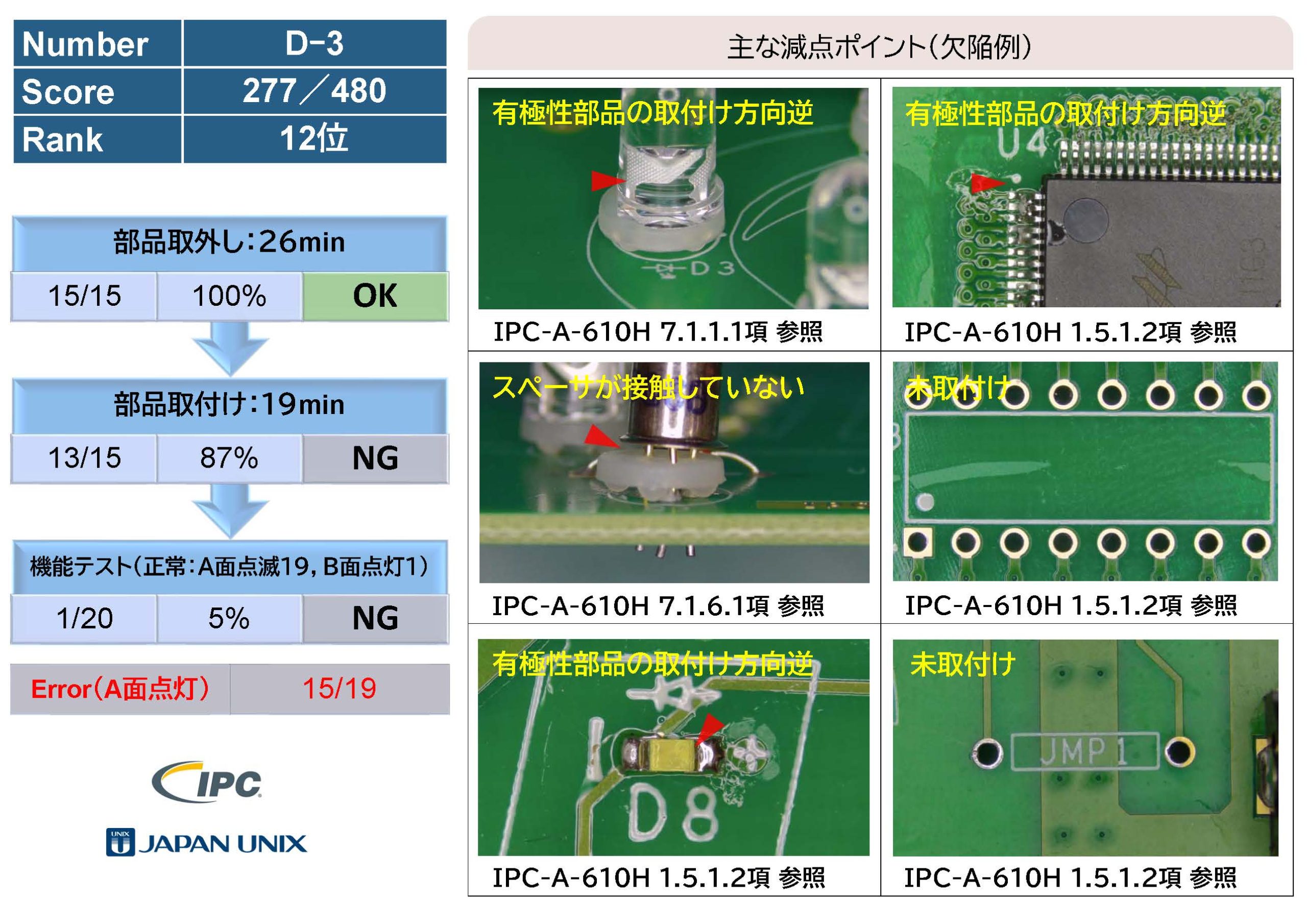

| 12th | 277/480 | D-3 |

| Rank | Score | Number |

|---|---|---|

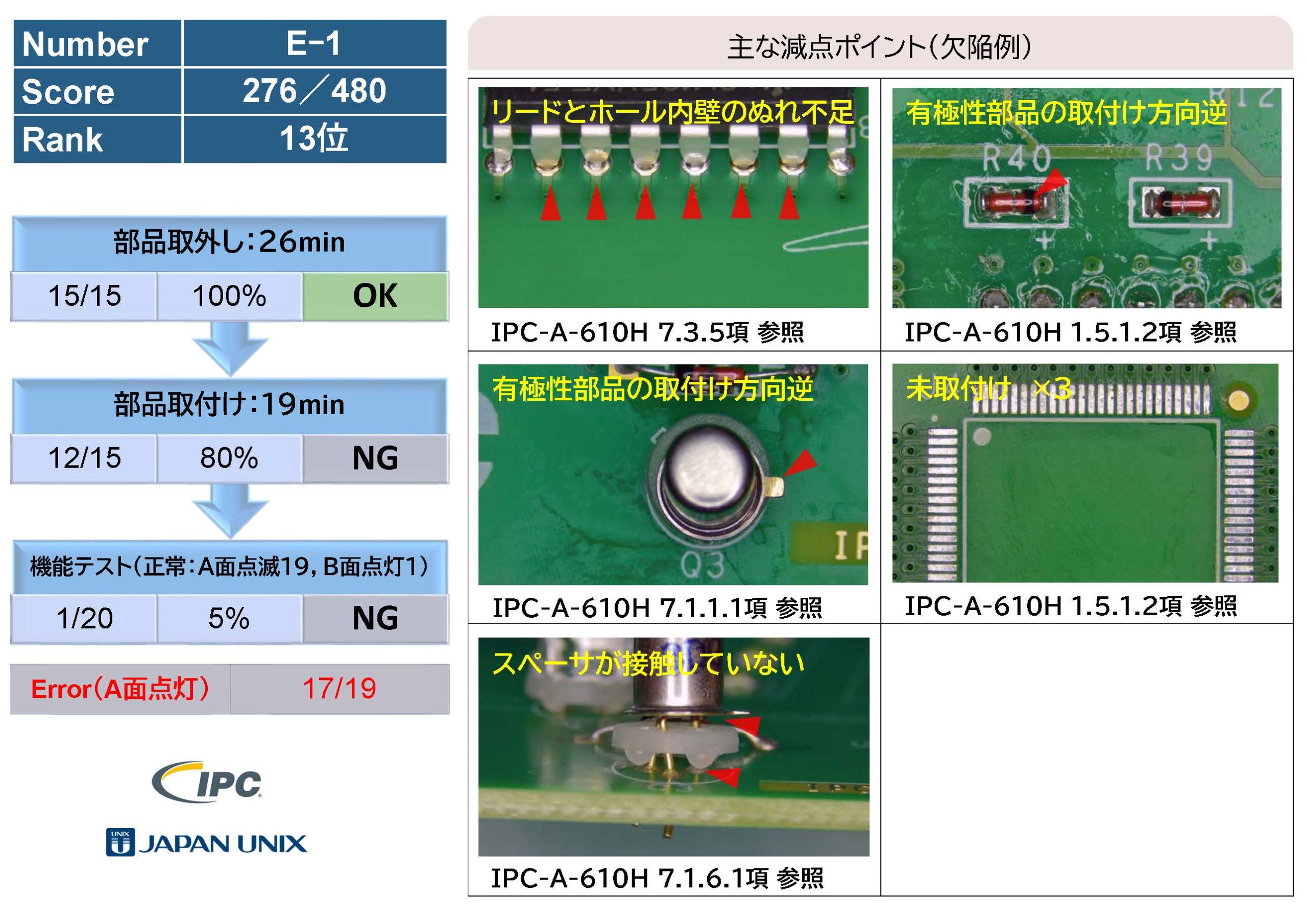

| 13th | 276/480 | E-1 |

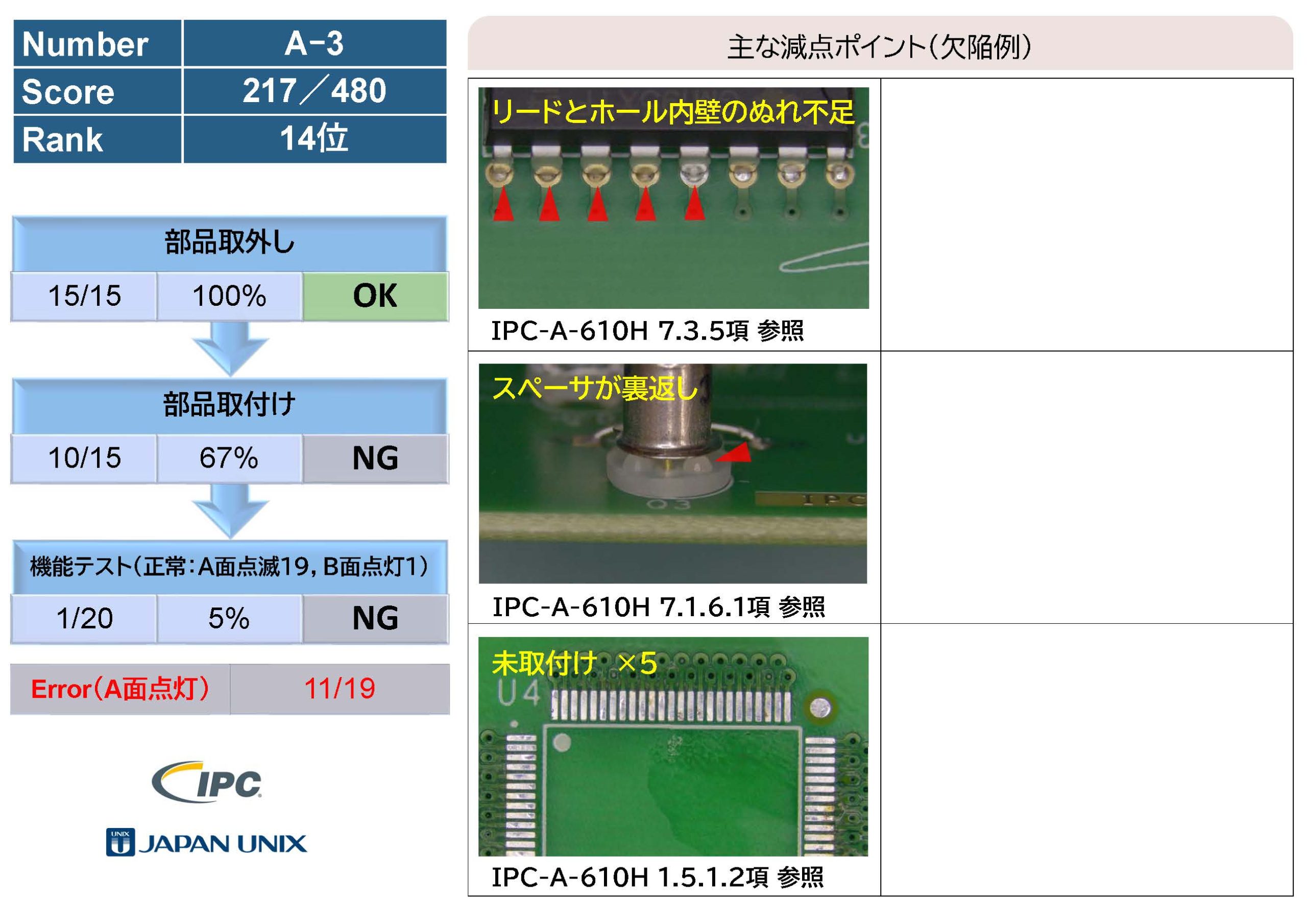

| 14th | 217/480 | A-3 |

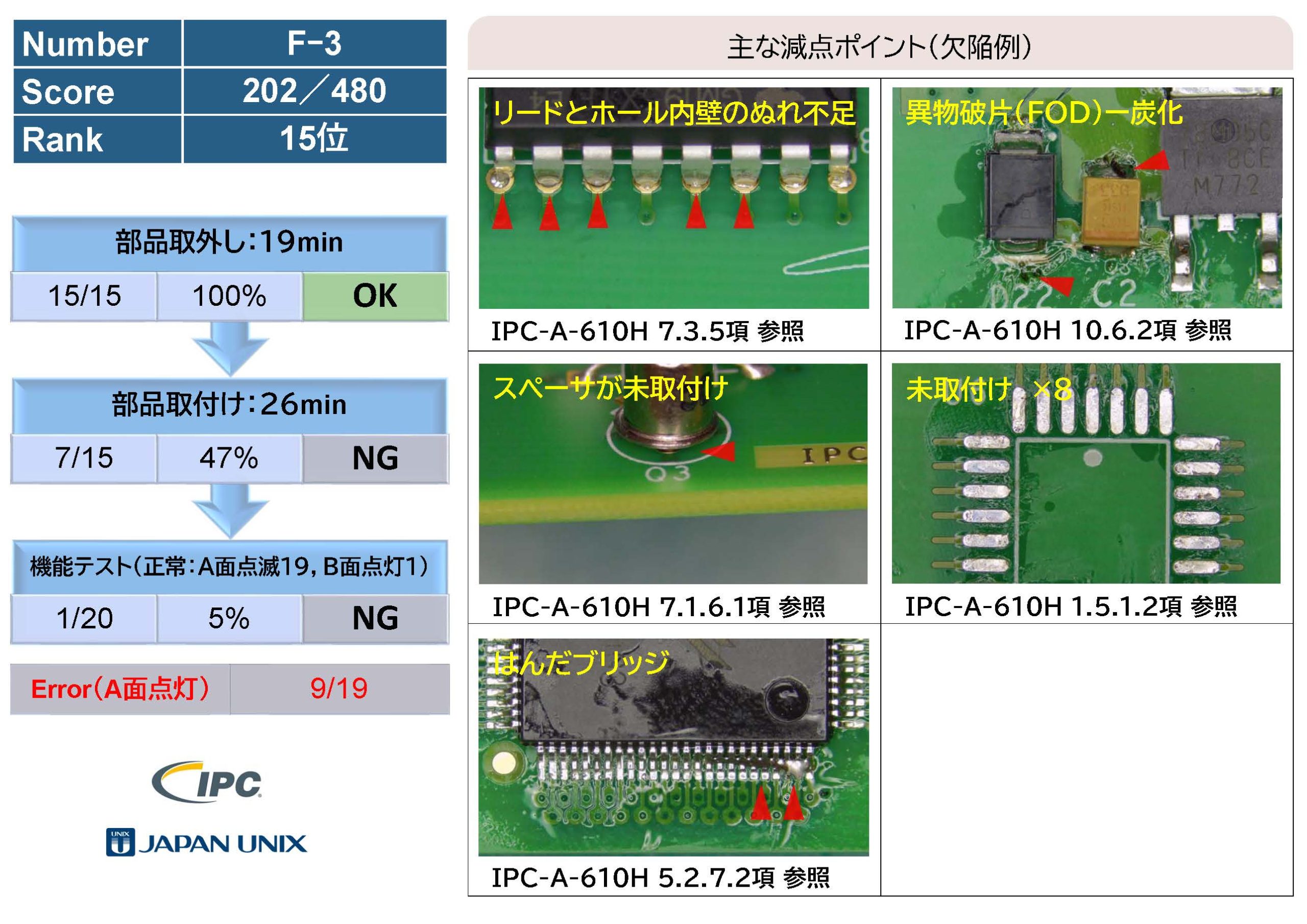

| 15th | 202/480 | F-3 |

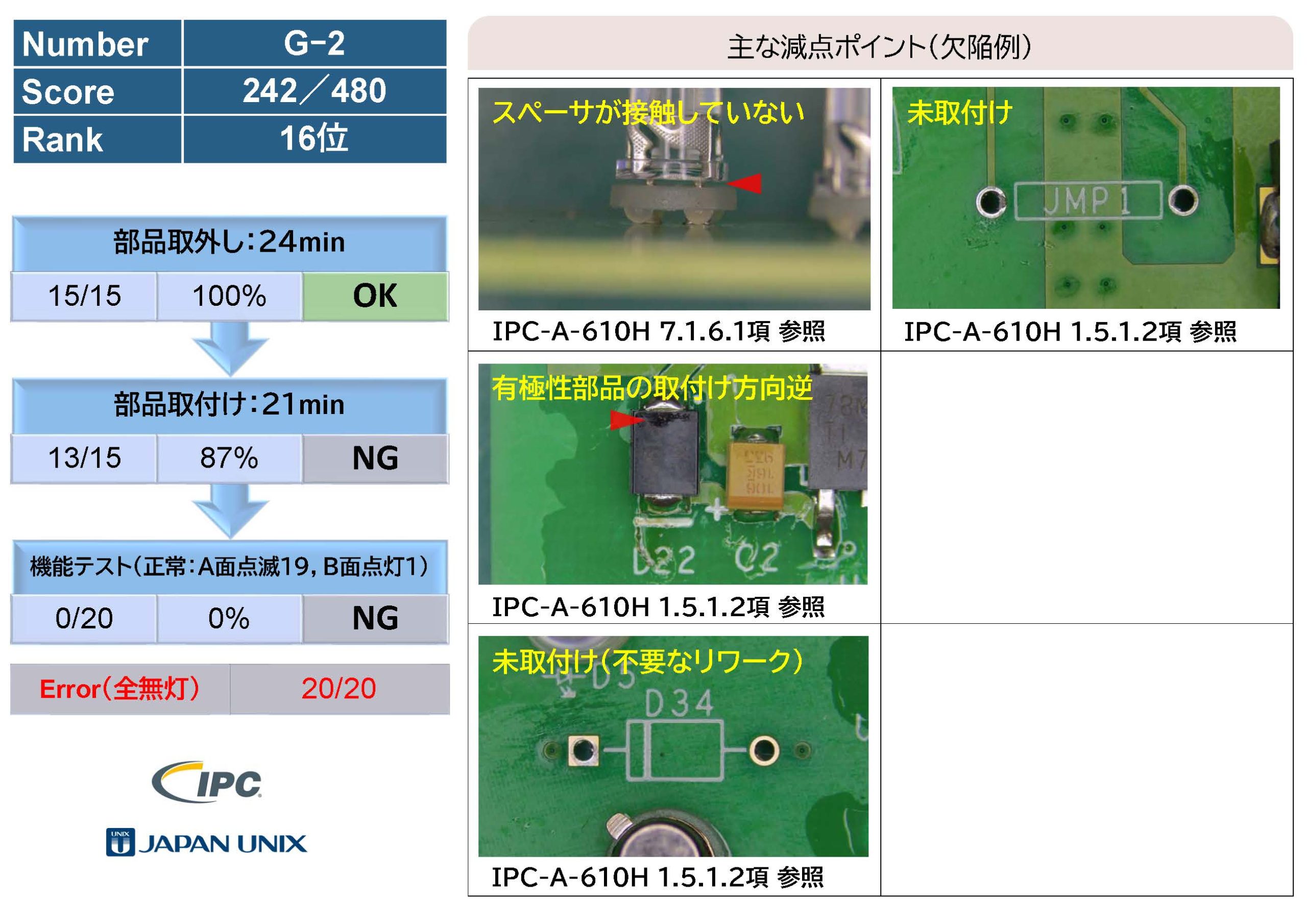

| 16th | 242/480 | G-2 |

| 17th | 208/480 | B-3 |

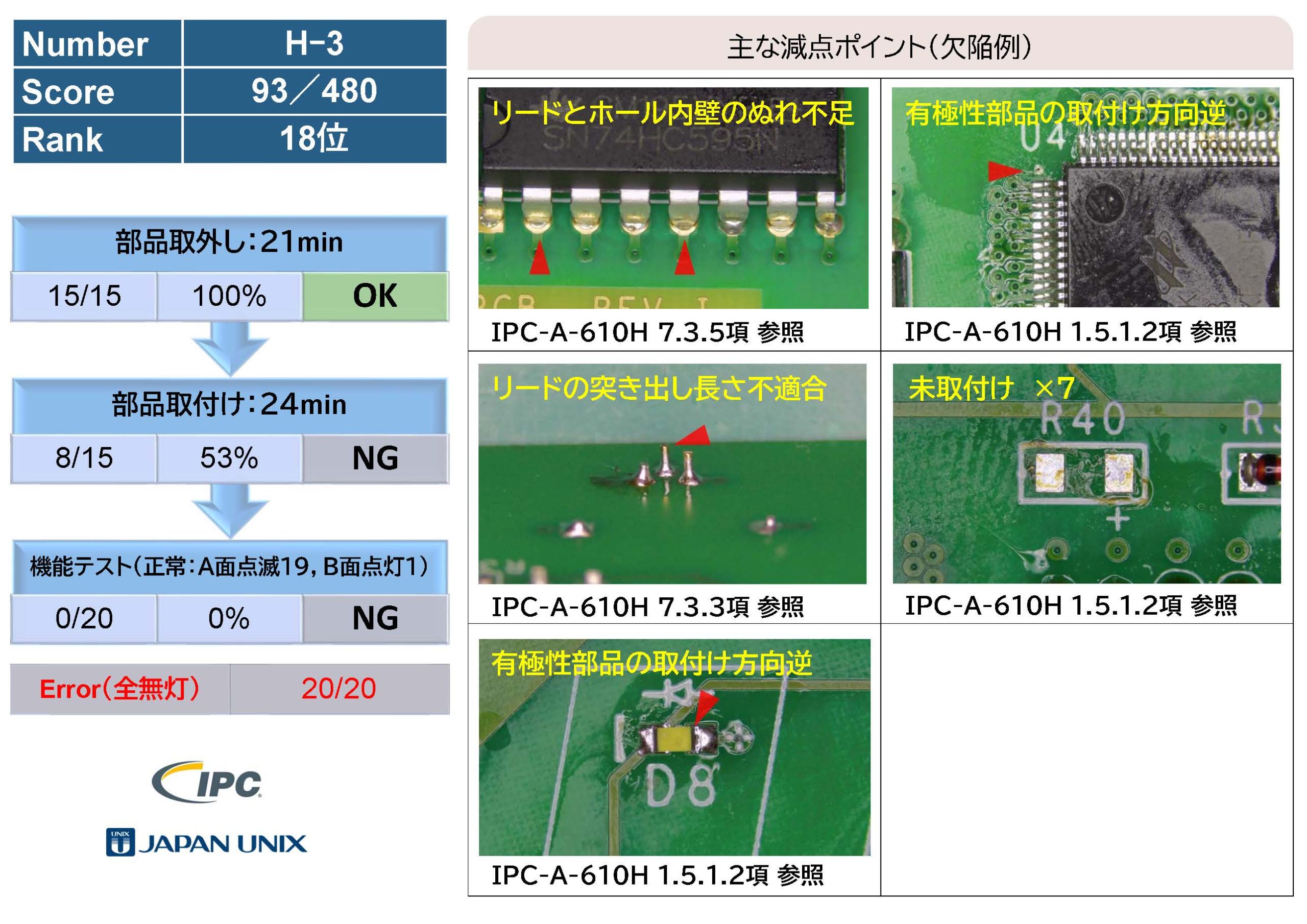

| 18th | 93/480 | H-3 |

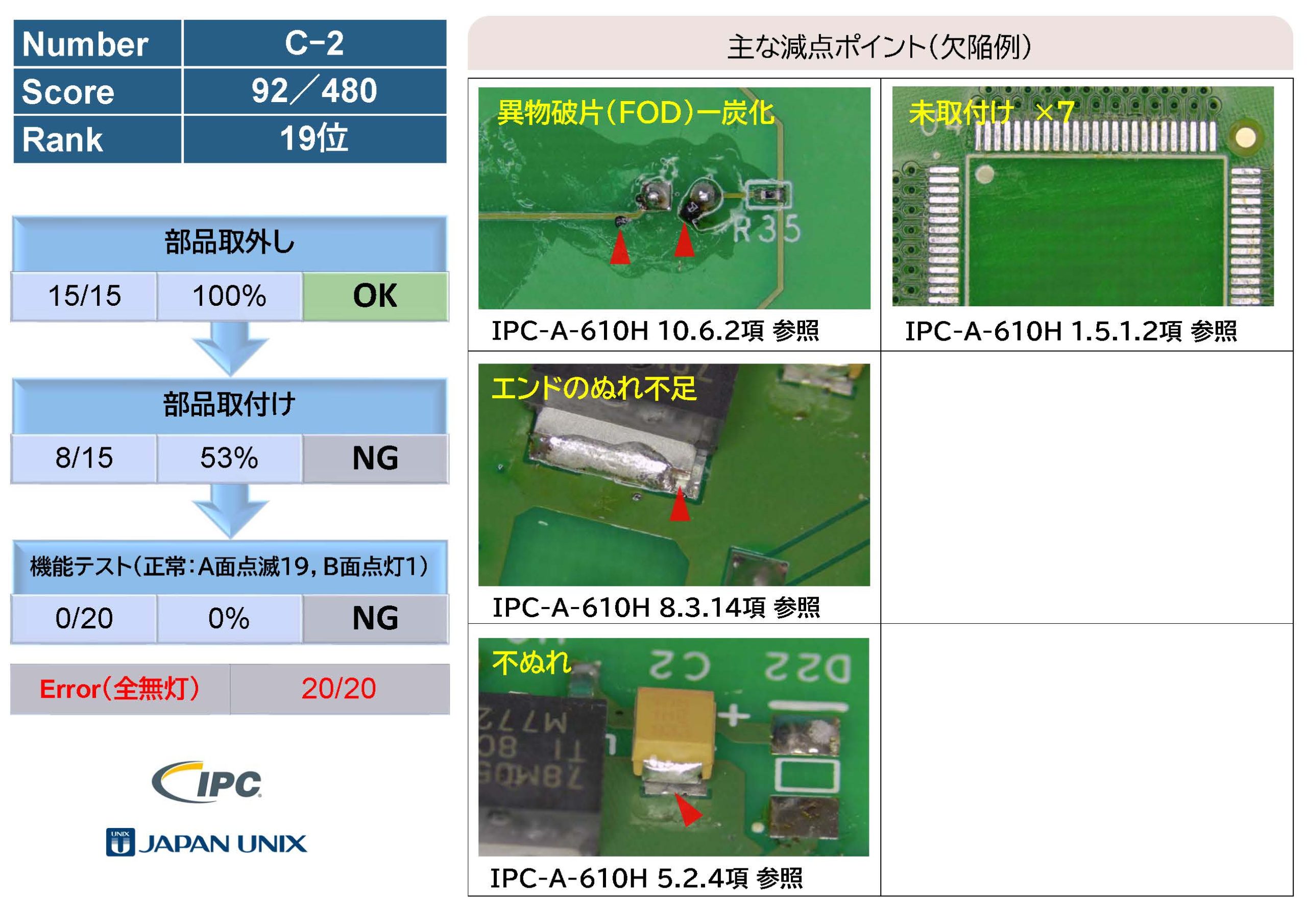

| 19th | 92/480 | C-2 |

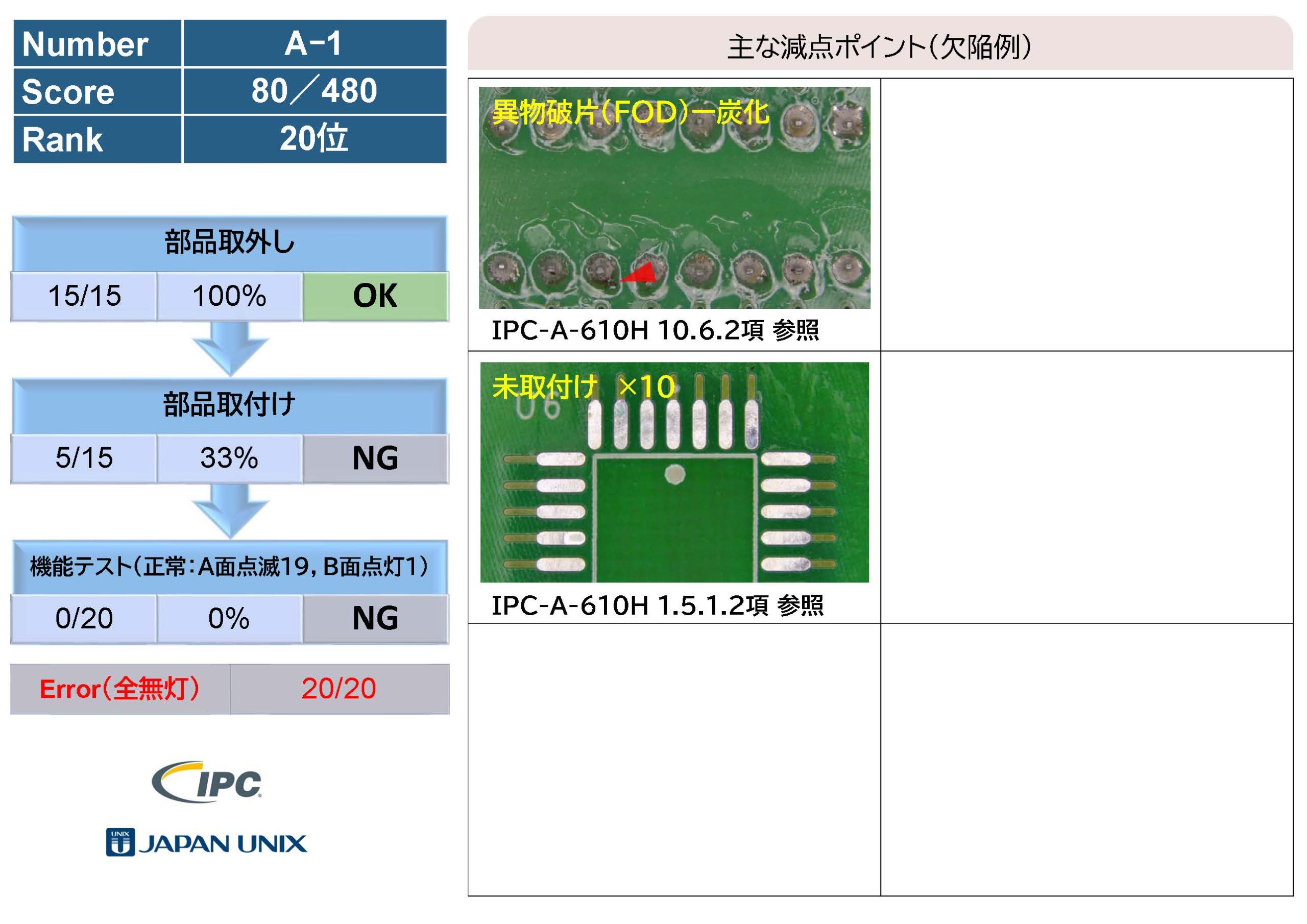

| 20th | 80/480 | A-1 |

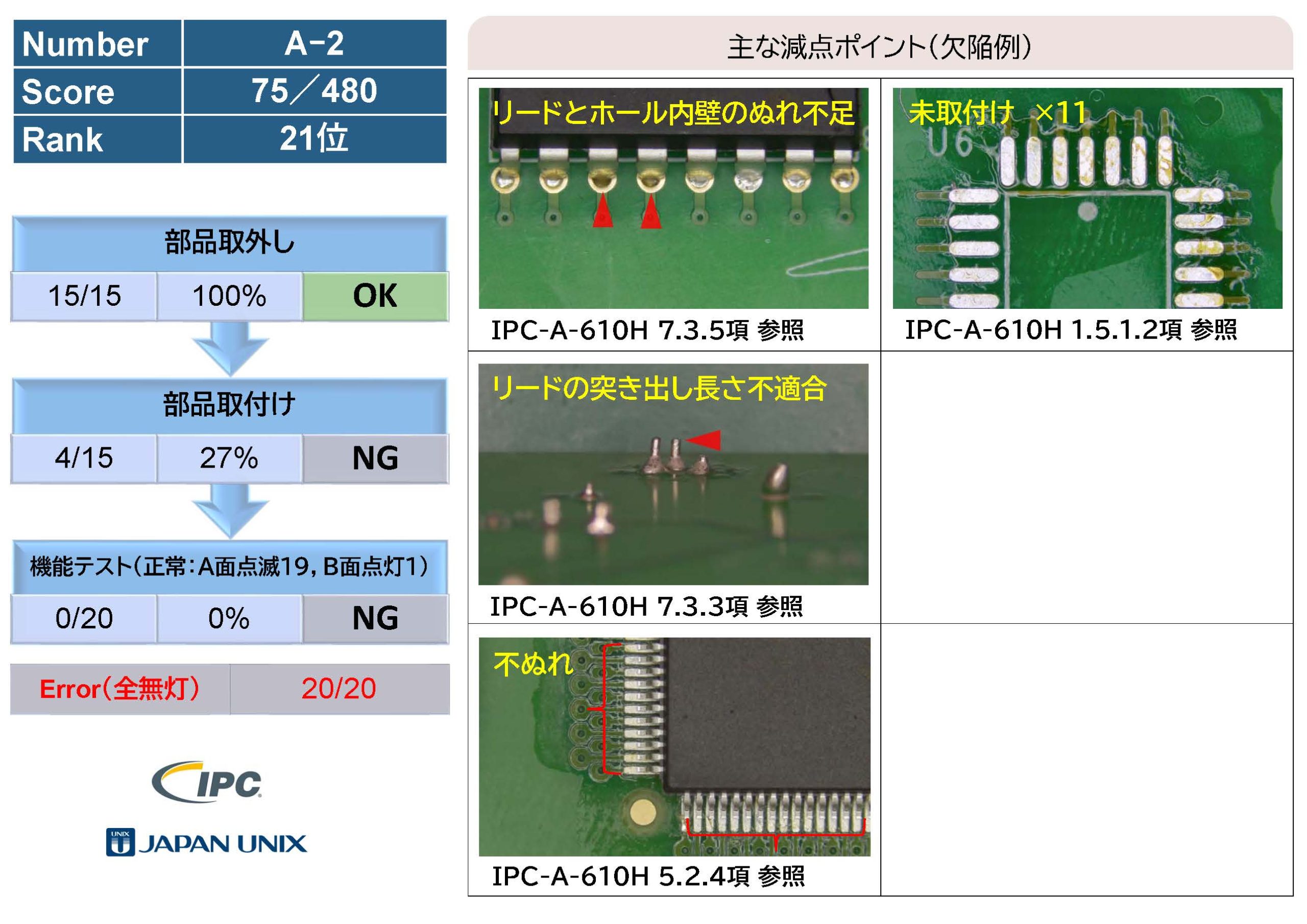

| 21st | 75/480 | A-2 |

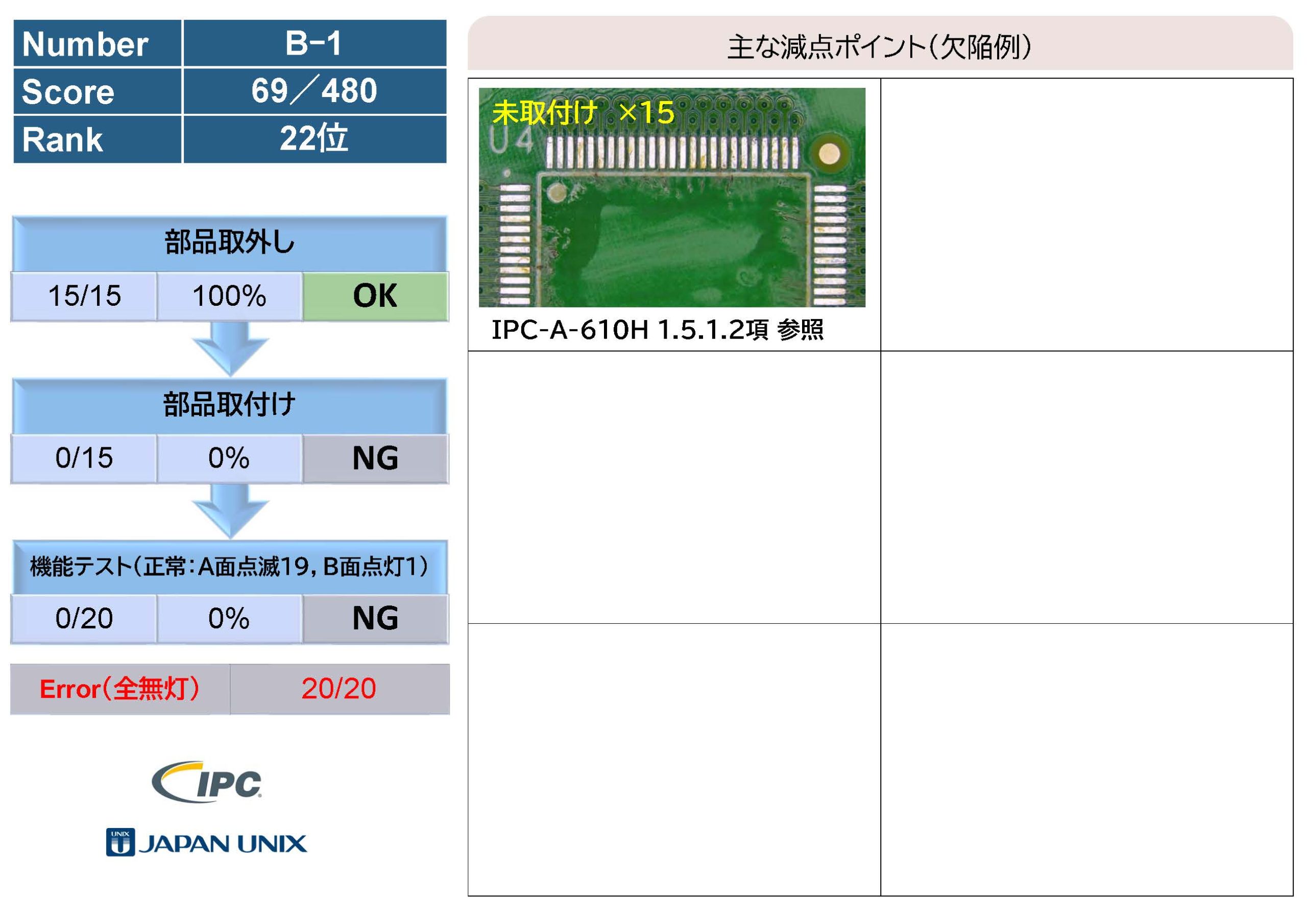

| 22nd | 69/480 | B-1 |

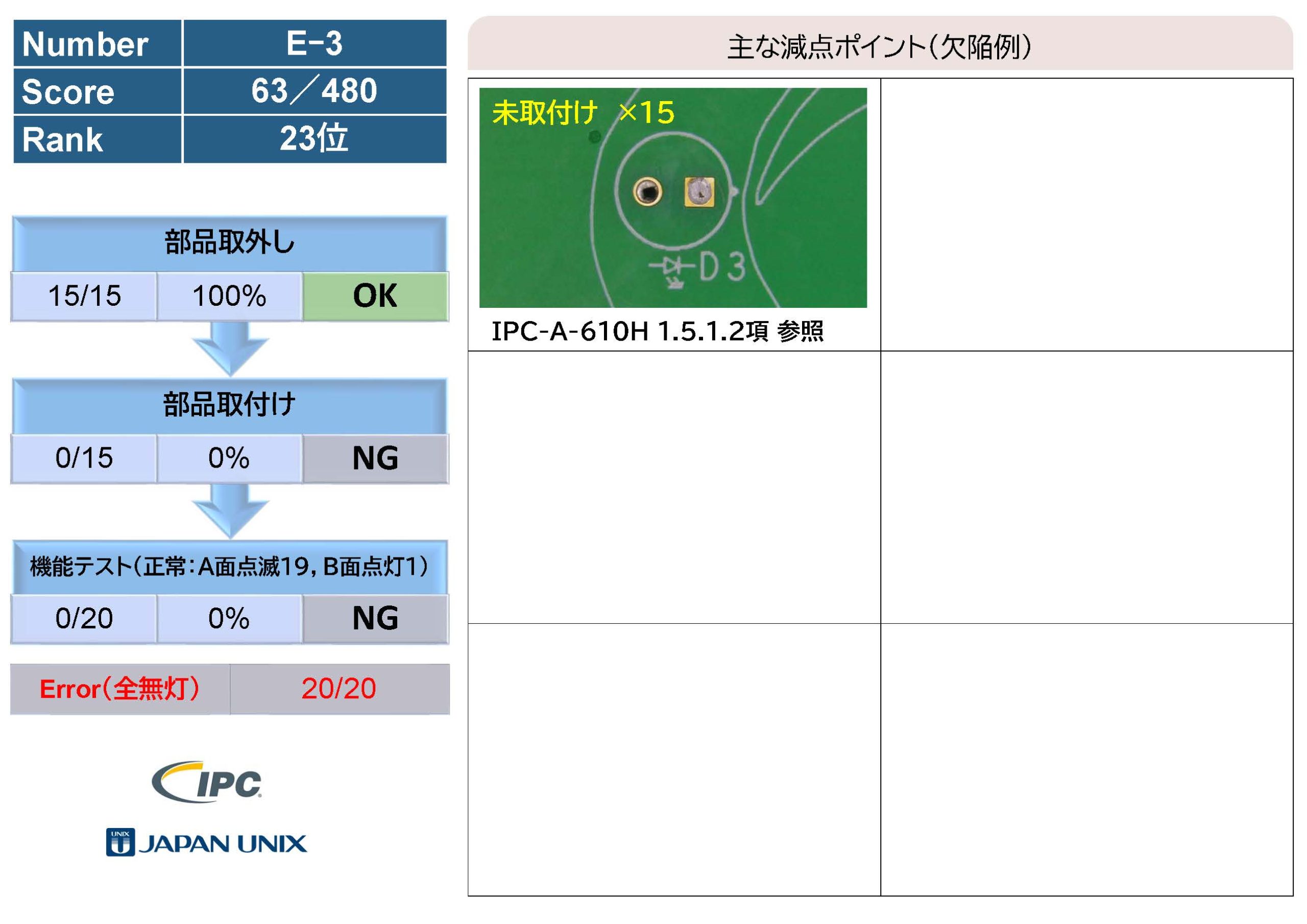

| 23rd | 63/480 | E-3 |

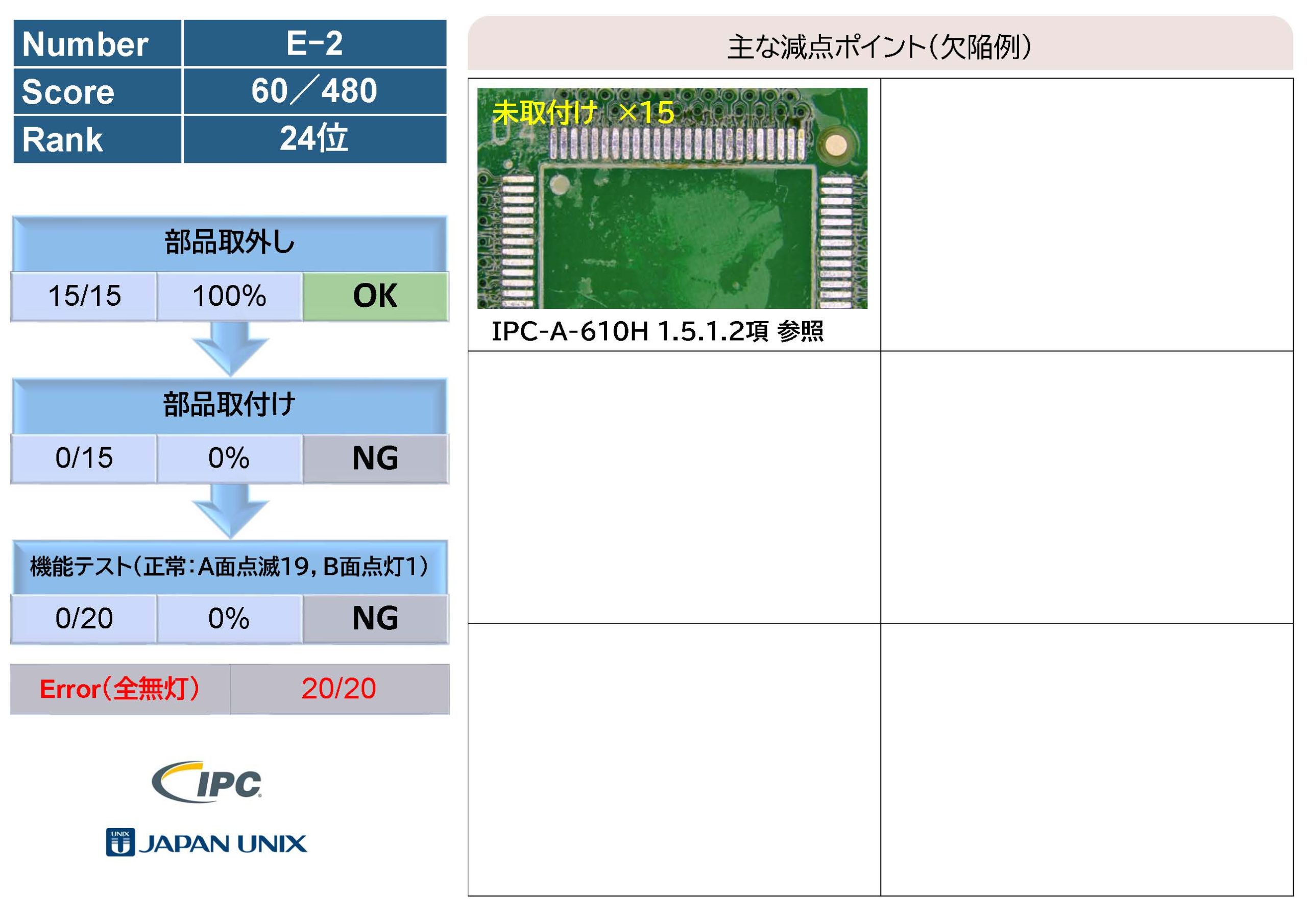

| 24th | 60/480 | E-2 |

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español