The rigorous soldering quality requirements of the aviation & aerospace industry

Aircraft and spacecraft are precision machines used in harsh environments. This section describes Japan Unix’s laser soldering technology, which is used by many companies in the aerospace industry.

Precision machinery used in the harshest environments on earth

Aircraft and spacecraft are precision machines composed of highly precise parts and electronic devices. Moreover, they are used in the harshest environments on earth, such as at altitudes exceeding 10,000 m and under oxygen-free conditions, where the temperature is minus 50degrees[celsius] and the air pressure is 240 hPa. To ensure that electronic control functions reliably even in such extreme environments, the design and manufacturing of electronic equipment requires the highest level of quality.

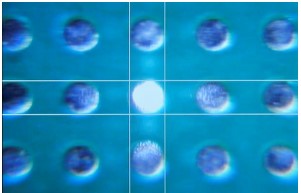

Electronic circuit boards for aircraft are usually thick and high-current. Moreover, the mounted components are small and heat sensitive, making it difficult to mount them in narrow pitches and at high densities. Therefore, laser soldering is ideal for the manufacture of aircraft and spacecraft, as it excels at ultra-fine components and can solder in tight and intricate spaces. In fact, many clients in the aerospace industry have adopted Japan Unix laser soldering.

Why Japan Unix is Chosen by the Aerospace Industry

(1) Knowledge of lasers

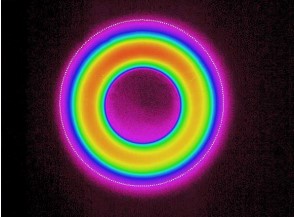

In order to introduce laser soldering and automate production processes in the aerospace industry, it is essential to have sufficient laser knowledge and technology. Japan Unix has developed its proprietary “Multi-φ Laser” technology that automatically changes the irradiation diameter according to the shape of the component and other factors. We also offer optimization proposals for lasers with irregular shapes, such as doughnut and ellipse lasers, to solve the problems of production efficiency and quality degradation on boards with a mixture of large and small parts.

(2) Soldering technology

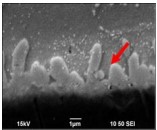

Soldering involves heating metals such as tin, silver, and copper and chemicals such as flux to accelerate chemical reactions that reduce surface tension of the metals before they solidify again. Designing optimal soldering requires not only accumulated experience, but also knowledge of metallurgy, fluid mechanics, chemistry, thermodynamics, mechanical engineering, and much more. Japan Unix has a “Soldering Lab” that scientifically analyzes soldering and trains many highly skilled soldering specialists.

(3) Robot control technology

Automating optimally designed soldering conditions requires automation knowledge, including robotics. Japan Unix has acquired many patents for technologies that precisely control heat source securing, wire solder feeding, and heat supply. In addition, we have accumulated decades of experience in robot automation and soldering data. As a rare soldering robot manufacturer that can clear the special requirement of “objects that move in places where humans cannot operate,” Japan Unix has received inquiries from all over the world.

To learn more about soldering challenges in the aerospace industry, Japan Unix’s laser technology, IPC soldering standards, and more, click here to download a PDF file.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español