ADVANTEST CORPORATION

“Visualize” your company’s strengths and communicate your superiority in the global marketplace

Strengths of Japanese companies in the global market and their ability to respond to market changes.

Advantest Corporation is a leading manufacturer of semiconductor test equipment, with overseas sales accounting for over 90% of total sales. Semiconductor test equipment, which requires extremely high precision, accurate, and high-speed processing, tends to incorporate larger and multi-layered electronic substrates, and requires advanced mounting technology for manufacturing. Advantest has been utilizing the IPC standard for two years now, and has successfully addressed various issues and established its own superiority in the global market.

name of companyAdvantest Corporationestablishment1954.Net sales (Consolidated)Approx. 162.1 billion yen (actual for the fiscal year ended March 31, 2016)Number of employees (consolidated)4,494 (excluding temporary and contract employees)

| Company Name | ADVANTEST CORPORATION |

|---|---|

| Founded | 1954 |

| Gross Sales | 162.1 billion yen(FY2016) |

| Number of employees | 4,494 |

| Business | Semiconductor and component test system business, mechatronics-related business, services, etc. |

The panelists discussed the trends in the global market and IPC initiatives in a panel discussion titled “Strengths of Japanese Companies in the Global Market and Their Ability to Respond to Market Changes. The benefits of IPC and its response to international standards.” The panelists discussed trends in the global market and IPC initiatives.

-Panelist:

Mr.Soichi Tsukagoshi(Managing Executive Officer and General Manager of Production Division)

Mr.Noboru Saito(General Manager of Production Engineering Department)

Mr.Hideki Ito(Functional Manager of Production Engineering Group, Production Engineering Department)

Dr.John W. Mitchell (President and CEO)

To learn more, click here to download the PDF file.

The supply chain we have built to date alone cannot meet global demand.

Global Market Trends and the Strengths and Challenges for Japanese Companies

Tsukagoshi : There are three things that I feel are changing in the global marketplace: First, there is polarization. The second is the “widening gap between the two. The third is “oligopoly,” in which powerful companies gain an advantage through mergers and acquisitions.

What are the advantages of Japanese companies in the global market? Both of them stress that “quality” and “reliability” are the key factors. On the other hand, as globalization progresses, it is becoming increasingly difficult for Japanese companies to handle all processes on their own. The challenge for Japanese companies is how to communicate their superiority to the rest of the world and build a strong and flexible supply chain.

Dr. Mitchell: These days, we are becoming more globally connected, with ‘connected’ as the key word. Japan is a leader in the electronics industry, but it has historically been inward-looking, so changing that environment will be a big challenge.

Verigy Ltd. acquisition triggers efforts to restructure supply chain

How will the introduction of IPC change the company?

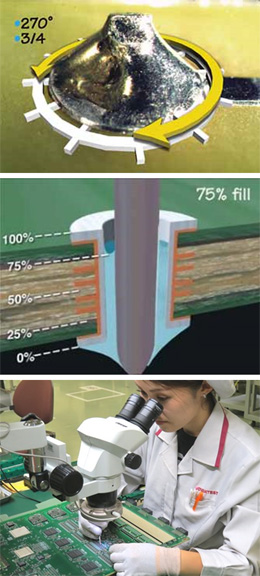

Advantest’s introduction of IPC was triggered by its acquisition of Verigy, a company spun off from Agilen Technologies. Until then, everything had been manufactured in-house, but Verigy utilized an EMS, and two different forms of production were incorporated into the company. This process has allowed the company to introduce international standards, but by comparing and complementing existing in-house standards, the company has been able to smoothly incorporate them without confusion.

Dr. Mitchell: The manufacturing quality of Japanese companies is so high that even if we introduced IPC, we would not have to make major changes to our processes. For example, during a meeting to determine the quality of a product, we may say, ‘Only the processes listed on pages 8-13 of IPC-A-610 should be processed using the special method we have specified. Otherwise, please proceed with Class 2 of IPC-A-610. If you make a request in this way, you will be able to communicate smoothly and clearly with the partners.

As a result, Advantest has succeeded in adding to its three existing strengths and gaining a strong advantage in the global marketplace.

- To be able to provide a one-stop solution for all equipment related to semiconductor testing.

- Must have high speed range measurement technology.

- High Reliability.

A new addition is the ability to distinguish between in-house production and external production using EMS. The introduction of IPC has further complemented the company’s original strengths and has enabled to explain the details of its business with overseas partners and clients.

How do we communicate this advantage to the world?

What is the importance of the IPC standardization process in the global market?

Mr.Tsukagoshi: PCB Mounting technologies are becoming increasingly difficult, and unless we establish our own soldering and assembly technologies, we will not be able to manufacture our products around the world and meet global demand. We will continue to utilize IPC to increase the number of excellent engineers we have around the world.

Dr. Mitchell: IPC wants to break down barriers between countries and create a smaller world through standardization. By getting Japanese companies to understand IPC, we can develop new business in the global marketplace.

To learn more, click here to download the PDF file.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español