Multi-diameter Laser

Optimizing laser exposure diameters to fit any component size or board patterns

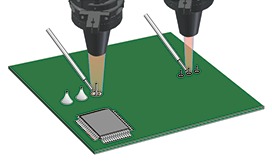

Laser beam spot diameters are adjustable without moving. The variable spot diameters allow ideal soldering outcomes to diverse component shapes or various land patterns. Due to designing the best conditions to each, not only quality but also speed is enhanced.

Multi-φ laser soldering(Multi-phi Laser)

Variable laser beam spot diameters soldering system

IMMOBILE

FLEXIBLE

OPTIMIZATION

Multi-φ Laser Overview

Name: Multi-φ Laser Soldering System (Multi-phi Laser)

Dimensions: 214mmx120mmx92mm

Power Supply: single-phase 220V±10%

Positioning System: coaxial observation using a CCD camera *1

Laser Exposure Diameter: Min. 0.6mm, Max. 3.0mm

Laser Exposure Distance: 30-120mm (1.18-4.72in)

Beam diameter : 0.6-3.0mm (0.024-0.12in)*1

Note: For customers already using our laser soldering, replacing new laser head is available. Please contact us regarding refinement and improvement of existing equipment.

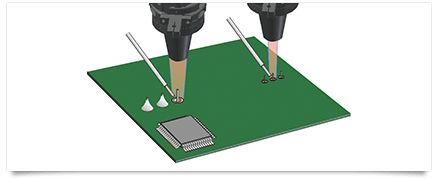

Sample of a multi-phi laser system-mounted apparatus

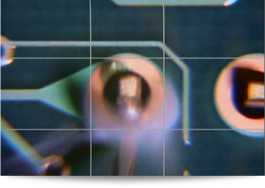

Changing diameters takes only 0.2 sec.*1. optimization will never negatively affect cycle time.

*1:The exact time may vary depending on users circumstances

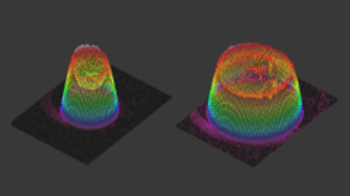

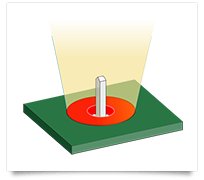

Max. diameter φ3.0mm

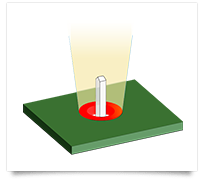

Min. diameter φ0.1mm

Once conditions are set, beam diameters are adjusted automatically according to each pad size.

Reference Videos

Typical failures caused from inappropriate diameter

Reasons and why a wrong choice of laser beam diameter easily causes you typical soldering problems

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español