What is the advantage of laser soldering? [YouTube Tech Article]

YouTube Tech Article

The Allure of Laser Soldering Explained in 4 Minutes

Watch the Video for this Tech Article

Theme

Host: Hello everyone, I’m Unokuchi, supporting your soldering life. Today, I want to continue from our previous tech article, which was an introduction to laser soldering. I want to talk about the advantages of laser soldering and share what our customers find attractive about it.

Japanunix has been using laser soldering for 20 years and introduced it to various customers. I’ve been asking them what they find appealing about it, and I want to share that with you today.

The Key Features of Laser Soldering

Host: The biggest feature of laser soldering is that it has minimal points of change. The reason for this is that it is a non-contact method.

The non-contact method has the advantage of contributing to stable quality.

Conditions

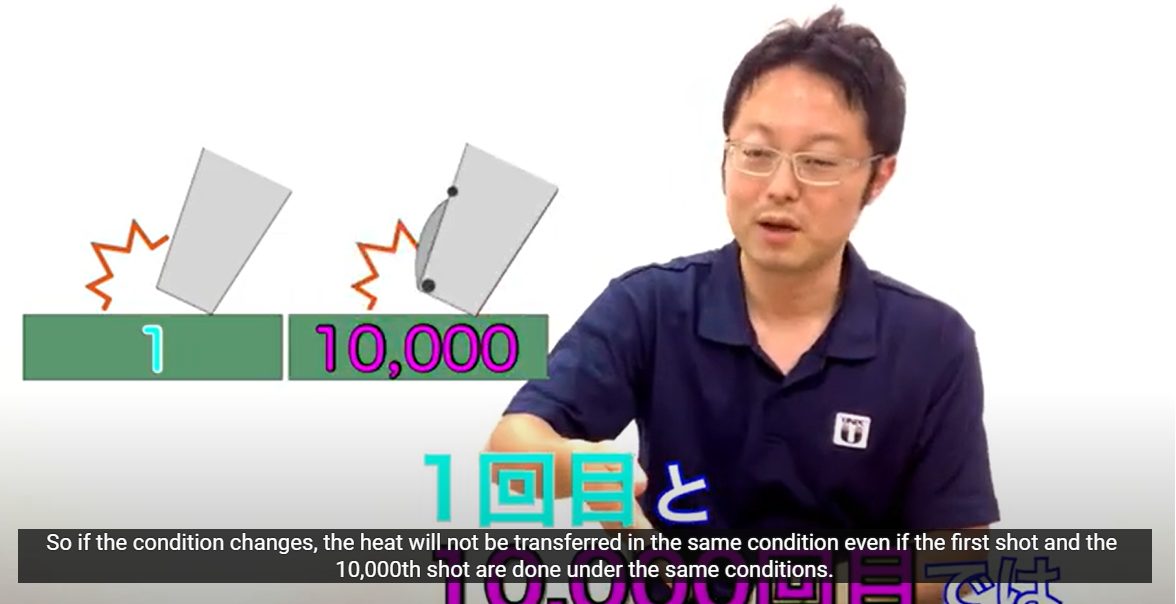

Host: In the case of contact soldering, there can be instances where solder comes off or the flux in the solder gets attached. Additionally, because heat is applied, the state can change due to carbonization and oxidation.

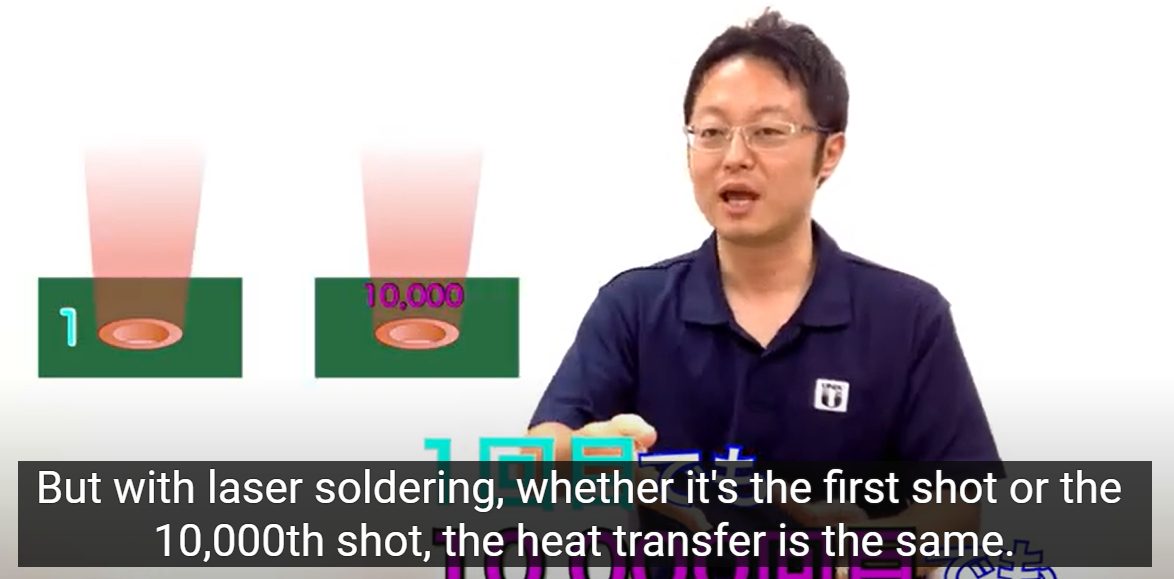

So, when the state changes, even if soldering is performed under the same conditions for the first and ten thousandth time, there can be differences in how heat is transmitted if the equipment is not maintained. While there are ways to compensate for this, laser soldering allows for consistent heat transfer and contributes to stable quality without the need for constant adjustment.

Maintenance

Host: Being a non-contact method, maintenance can be significantly reduced. As I mentioned earlier, in contact methods, various substances can get attached. However, in non-contact methods, they don’t get attached, so there’s no need for cleaning or replacement.

The time spent on cleaning and replacement involves stopping the equipment, and since other work is also paused during that time, minimizing the downtime is a significant advantage for both the personnel and overall operation.

Running Cost

Host: In terms of operating cost and running cost, it is also very low. As mentioned before, there are consumables. However, they are minimal, including replacement parts and solder materials. In conventional methods like solder pots, not all the solder in the pot is used for soldering. Some of it inevitably needs to be discarded.

Additionally, there is the cost of electricity required to heat the solder pot. When heating a large apparatus, it incurs a significant amount of electricity cost. But with laser soldering, only the part being heated and irradiated uses energy, so the running cost for operation is very low.

Summary

Host: So, these are the three advantages I mentioned: stable quality, minimal downtime, and low consumables and running costs. These advantages are derived from the minimal points of change. I believe this is the reason why laser soldering has experienced significant growth in the past decade.

In the future, we want to continue sharing information about laser soldering and other soldering methods. Thank you, and see you next time!

Related Products & Services

Watch the Video for this tech article

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español