What is a soldering robot? What are the benefits and future challenges of automation?

What is a soldering robot? The benefits and future challenges of automation.

Table of Contents

- Soldering Robots Automate Soldering Operations

- Difference between Mass Soldering Systems and Soldering Robots

- Advantages of soldering robots

- Challenges with soldering robots

- History of soldering robots

- Current soldering robots (Types & Products)

- Future requirements for soldering robots

- Continuous evolution of soldering robots

Soldering Robot for Automated Soldering Work

A soldering robot is a specialized industrial robot designed for automated soldering processes. It serves as a key component in automated electronics assembly lines, replacing manual tasks with high precision.

The first appearance of soldering robots can be traced back to the 1970s when industrial robots such as those used in automobile assembly, welding, and painting were introduced. Initially, these robots had a soldering iron attached to the end of their arm, but their precision was not sufficient at that time. Even after the introduction of soldering robots, soldering remained primarily a skilled craftsmanship performed by experienced workers.

However, with technological advancements, the precision of soldering robots has significantly improved. The transition to lead-free soldering since the 2000s increased the difficulty of the process, making automation more critical. Furthermore, factors such as the increasing complexity of circuit board designs, labor shortages, and the challenge of knowledge transfer have contributed to the widespread adoption of soldering robots.

The significant difference between humans and robots lies in the time required to acquire proficiency. Skilled human operators can make fine adjustments based on their senses, making them suitable for soldering delicate components. However, achieving that level of skill requires extensive training.

Modern robots, on the other hand, can start operating immediately after initial setup and are capable of soldering at a higher speed and consistent quality from day one.

Differences between Mass Soldering Systems and Soldering Robots

There are two main methods for automating soldering: “Mass Soldering Systems (Wave / Reflow),” which efficiently perform soldering in batches, and “Soldering Robots (Selective Soldering),” which perform precise and detailed soldering (point soldering). Each has its strengths and is used selectively in production lines.

Mass Soldering (Automated Soldering Equipment)

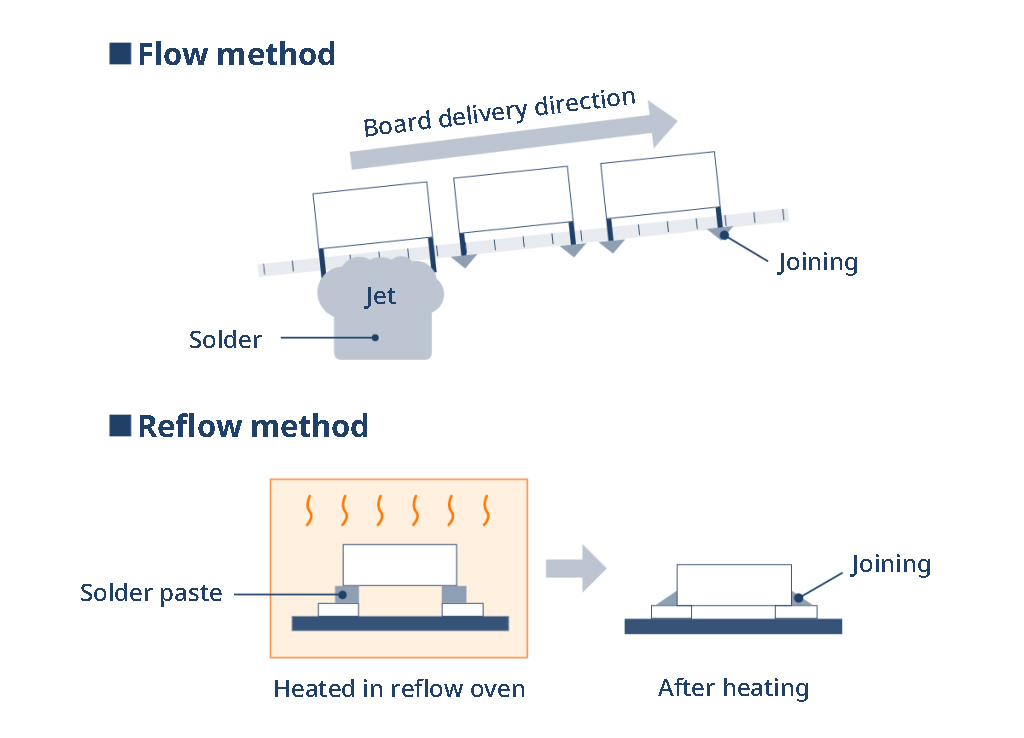

Mass soldering is suitable for efficiently producing large quantities of the same item. The two main methods are:

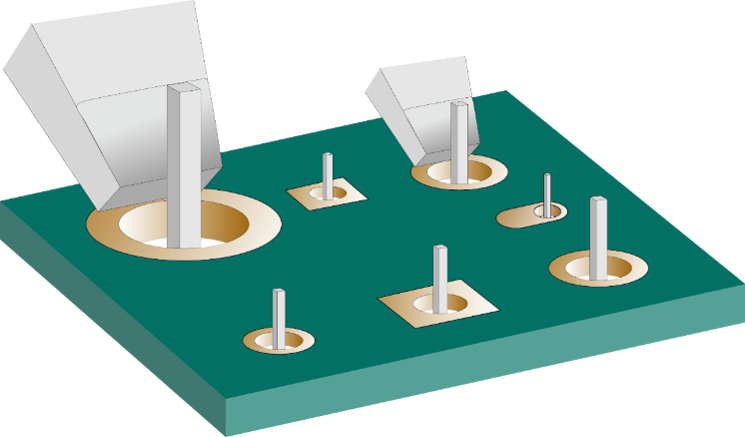

- Flow Method (Wave Soldering): Applying pre-melted solder to the soldering area.

- Reflow Method: Applying solder paste, placing components, and melting the solder via heat.

Both methods are ideal for bulk soldering of electronic components. However, the flow method is not suitable for fine soldering in densely packed areas, and the reflow method cannot be used for heat-sensitive components that cannot withstand the oven’s temperature.

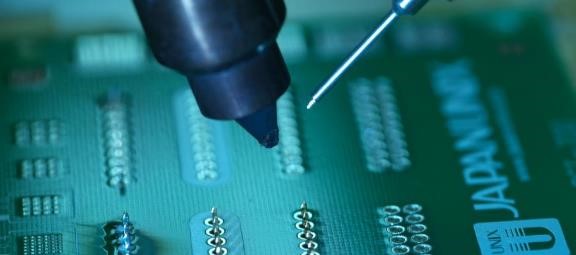

Soldering Robots (Selective Soldering)

Soldering robots are designed for post-process soldering or high-mix production. They excel at:

- Selective soldering (point soldering)

- Soldering heat-sensitive components (avoiding thermal stress on the whole board)

- Precise soldering in high-density areas

Their strength lies in the ability to perform these tasks accurately and repeatedly, complementing the mass soldering process.

Advantages of Soldering Robots

Soldering robots offer three main advantages: “reproducibility,” “stabilization of quality,” and “visualization of data.”

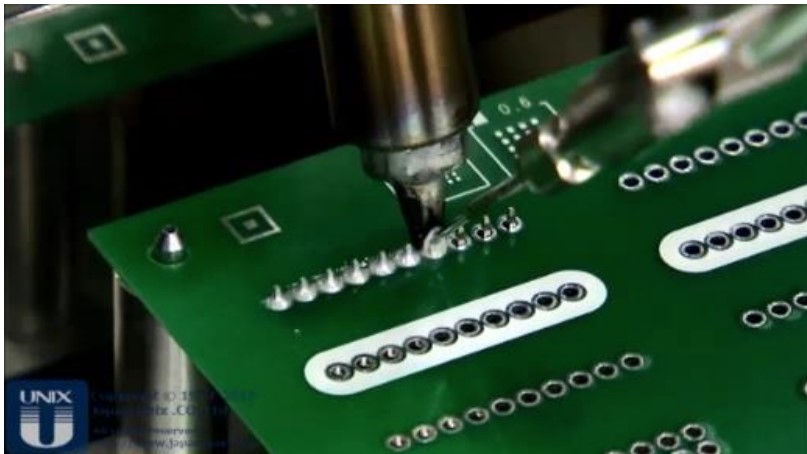

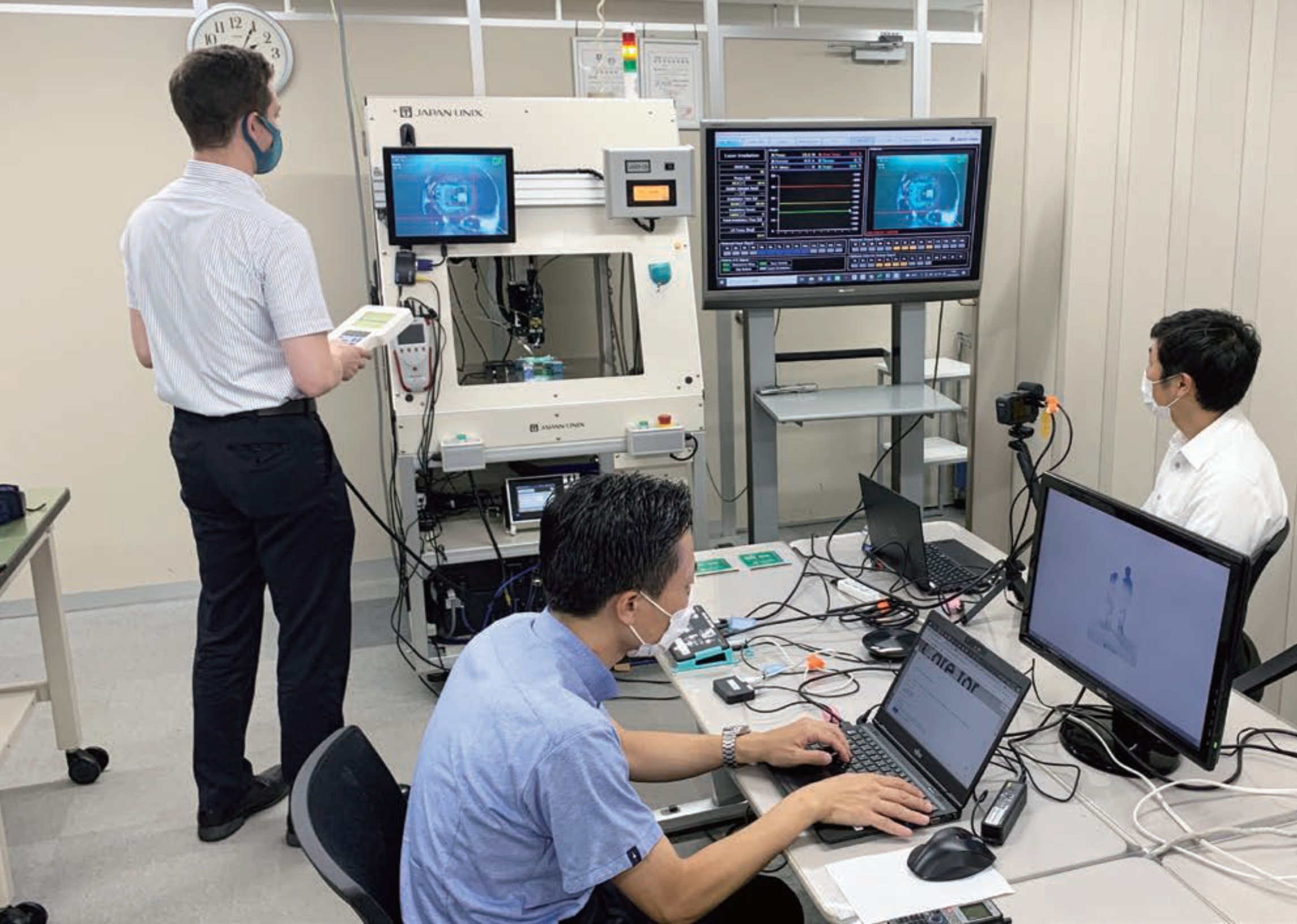

For example, in the case of Japan Unix’s soldering robots, the soldering position is adjusted with a correction accuracy of ±0.05mm using a tip position correction mechanism, ensuring high reproducibility.

Furthermore, by setting optimal conditions for up to 255 profiles—such as solder feed amount, speed, and approach angle—they achieve stable soldering quality.

Additionally, various log data can be stored, ensuring traceability. It is possible to monitor soldering temperatures, set counters, save error histories, and manage production via QR codes.

By introducing soldering robots, manufacturers can achieve higher speed and accuracy compared to manual operations, leading to improved throughput and reduced defect rates.

Challenges for Soldering Robots

Historically, soldering robots struggled with tasks such as “extremely narrow areas,” “products difficult to fix with jigs (like harnesses),” and “high-mix, low-volume products” requiring frequent changeovers.

However, advanced technologies like Laser Soldering are overcoming the issue of narrow access where iron tips cannot reach. While robots are becoming more versatile, skilled human operators are still valuable for specific, non-standardized tasks. The goal is to let robots handle the repetitive precision work, allowing humans to focus on complex decision-making.

History of Soldering Robots

Soldering requires dexterity, visual judgment, and experience, which is why its automation took longer compared to general industrial robots (welding/painting).

Japan Unix developed the first soldering robot aimed at replicating “human hand movements” in the early 1980s. In 1985, the vertical multiple-joint 5-axis soldering robot “UNIX-511” was completed. Since then, we have continuously improved performance, repeatability, and speed.

Previously considered a “replacement for simple tasks,” user needs have now shifted to “using robots for high-precision tasks that are difficult for humans.”

Types of Soldering Robots Based on Structure

Japan Unix offers various configurations to match your production line:

Demands for Future Soldering Robots

The manufacturing industry faces challenges such as labor shortages, skill transfer, and the transition to carbon neutrality (SDGs). Soldering robots are key to addressing these issues.

Addressing Labor Shortages

While robots alleviate labor shortages, they introduce maintenance needs. Future demands include reproducible functions and automated maintenance to reduce downtime caused by flux cleaning or tip replacement.

Further Visualization (DX)

To optimize efficiency, “visualizing” the manufacturing floor through DX is essential. Soldering robots must break down skilled processes into quantifiable data. Software solutions like Soldering Manager help visualize quality, speed, and troubleshooting, enabling anyone to manage production effectively.

Adapting to High-Mix Low-Volume Production

As products become more customized, production lines must support high-mix, low-volume runs. Soldering robots need flexibility—supporting multi-variety production with simplified program switching and versatile hardware.

Approaching CO2 Reduction Goals (SDGs)

Environmental consideration is now a global standard. Manufacturers are setting CO2 reduction goals. In this context, there is increasing demand for energy-efficient solutions. Laser Soldering is gaining attention as it applies heat only to the specific point required, significantly avoiding unnecessary power consumption compared to maintaining a large solder bath.

The Evolution of Soldering Robots Will Continue

Soldering robots have evolved remarkably since the late 20th century. While they lack human senses (vision, touch), advancements in sensing technology are bridging the gap. Future developments in robot hardware, software, and AI integration will continue to bring robots closer to the level of skilled master craftsmen.

Related Products & Services

Related Videos

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español