Iron Tip Shapes and Applications

Iron Tip Shapes and Applications

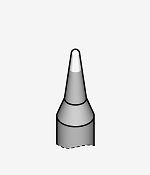

Conical

Universal type, small diameter is the mainstream. Ideal for fine soldering. The conical shape allows the same application to be performed on any surface. It is one of the general tip shapes often used for fine soldering without the need to change grips.

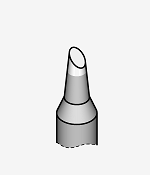

Bevel

(Conical and Cut Tip)

Heat is transferred to a wide surface from the angle at which the hand grips the tip. The tip has a C-cut (sloping cut) and the contact surface of the tip is wide even when the grip hold like a pencil. The same diameter all the way to the tip is suitable for parts with large heat capacity. Also used to clean solder surfaces during rework.

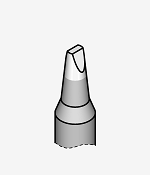

Chisel

(Screwdriver Type)

The tip is shaped like a flathead screwdriver and has a large contact surface. Suitable for chip parts and large parts. There are various types of chisels from very small to wide for various chip components and components with rectangular surfaces, and it is the general shape for surface-mounted components.

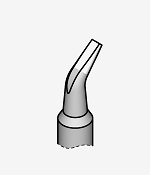

Conical Bent

The iron tip can contact easily in places where it is difficult to approach, enabling advantageous work. Even if the grip hold like a pencil, the tip of the soldering iron naturally points toward the connection point. Essential for devices with terminals that do not protrude from the surface or for thin shapes (J-lead and I-lead parts, etc.).

Bevel Bent

(Bent Conical and Cut Tip)

The iron tip can contact easily in places where it is difficult to approach, enabling advantageous work. The cut tip provides a wide contact surface with the component electrode or board pad. The cut surface can be adjusted angle to use in both large and small heat capacities.

Chisel Bent

(Bent screwdriver type)

The iron tip can contact easily in places where it is difficult to approach, enabling advantageous work. The flat-head screwdriver shape allows a larger contact area than other tip shapes, making it suitable for chip parts and large parts.

Spoon Tip

The spoon has an indentation inside the cut surface to fill with molten solder, making it ideal for soldering QFPs and other multi-pin soldering. Linear soldering requires continuous feeding of a constant amount of solder, and this shape eliminates uneven feeding and keep stable soldering quality.

Blade knife

Used for mounting and removing wide components, such as DIPs and SOPs, and has the advantage of being able to heat multiple points at the same time. On the other hand, it is not suitable for adjusting and correcting individual soldering points. Knife type can also be used for fixing solder bridge.

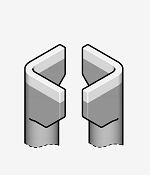

Unique Shape

One of the unique shapes for specific components such as QFPs, etc. Used for QFP removal because it can heat the lead pins on all four sides at the same time. The shape is suited to the specific component, thus minimizing damage to peripheral components and patterns.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español