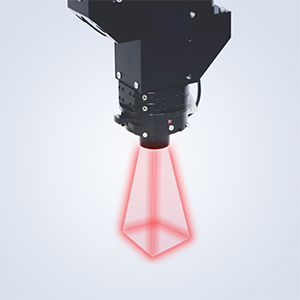

Area Laser (Simultaneous Multi-point Soldering Method)

What is Area Laser Soldering that covers from SMT to back-end process?

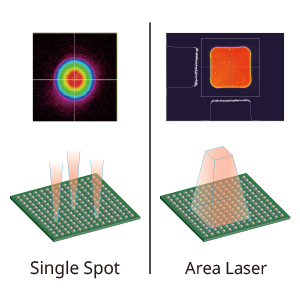

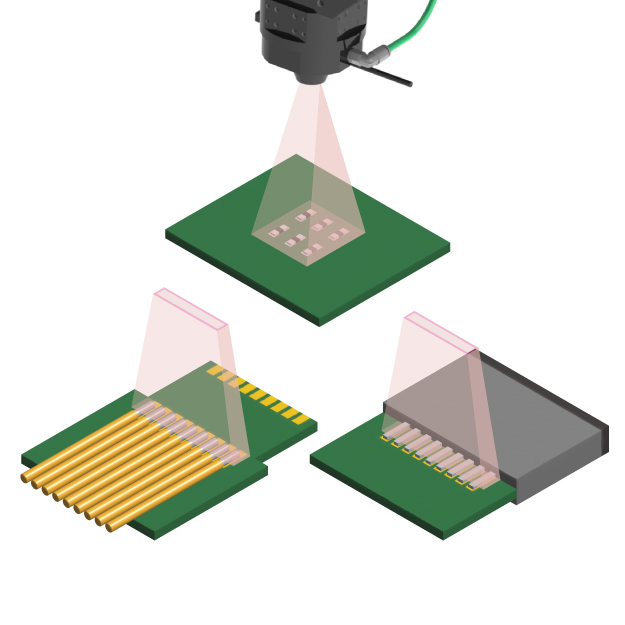

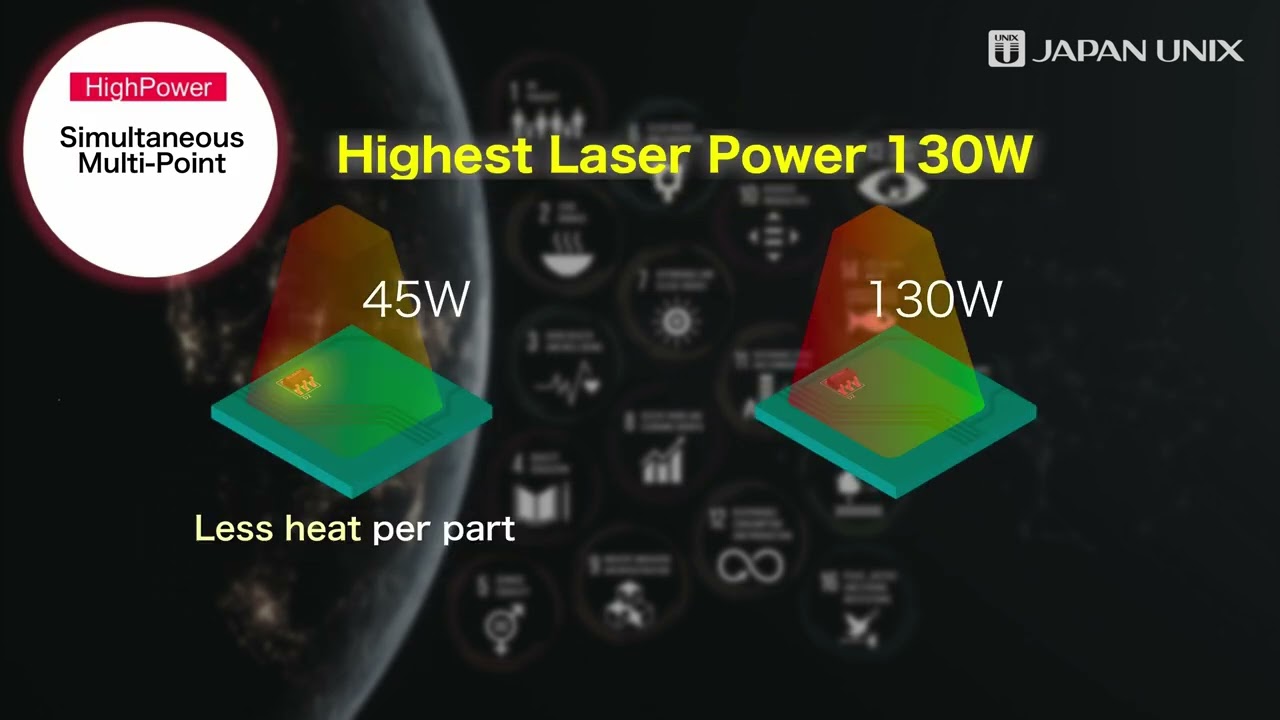

Unlike conventional single-spot lasers, these lasers can irradiate a wide area with uniform energy density.

This enables selective SMT processes and simultaneous multi-point soldering.

Feature

Spot SMT Process

(Selective Reflow)

Selective heating of the area irradiated by the area laser, rather than total heating, reduces the heat load on components.

Compared to reflow ovens, this system saves space and power.

Simultaneous Multi-point Soldering

Even items with a large number of points, such as FFC, can be soldered at the same time, contributing to shorter cycle time.

Uniform Energy

Provides uniform heat supply within the irradiated area.

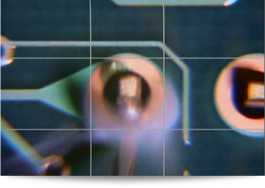

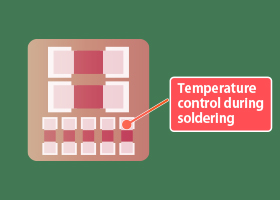

Temperature Management with ThermoPro™

Temperature control using Thermo Pro reduces the thermal load on components.

By performing temperature management even when soldering components with different thermal capacities, the area laser profile control is performed to achieve the ideal temperature profile.

Reference Videos

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español